21

22

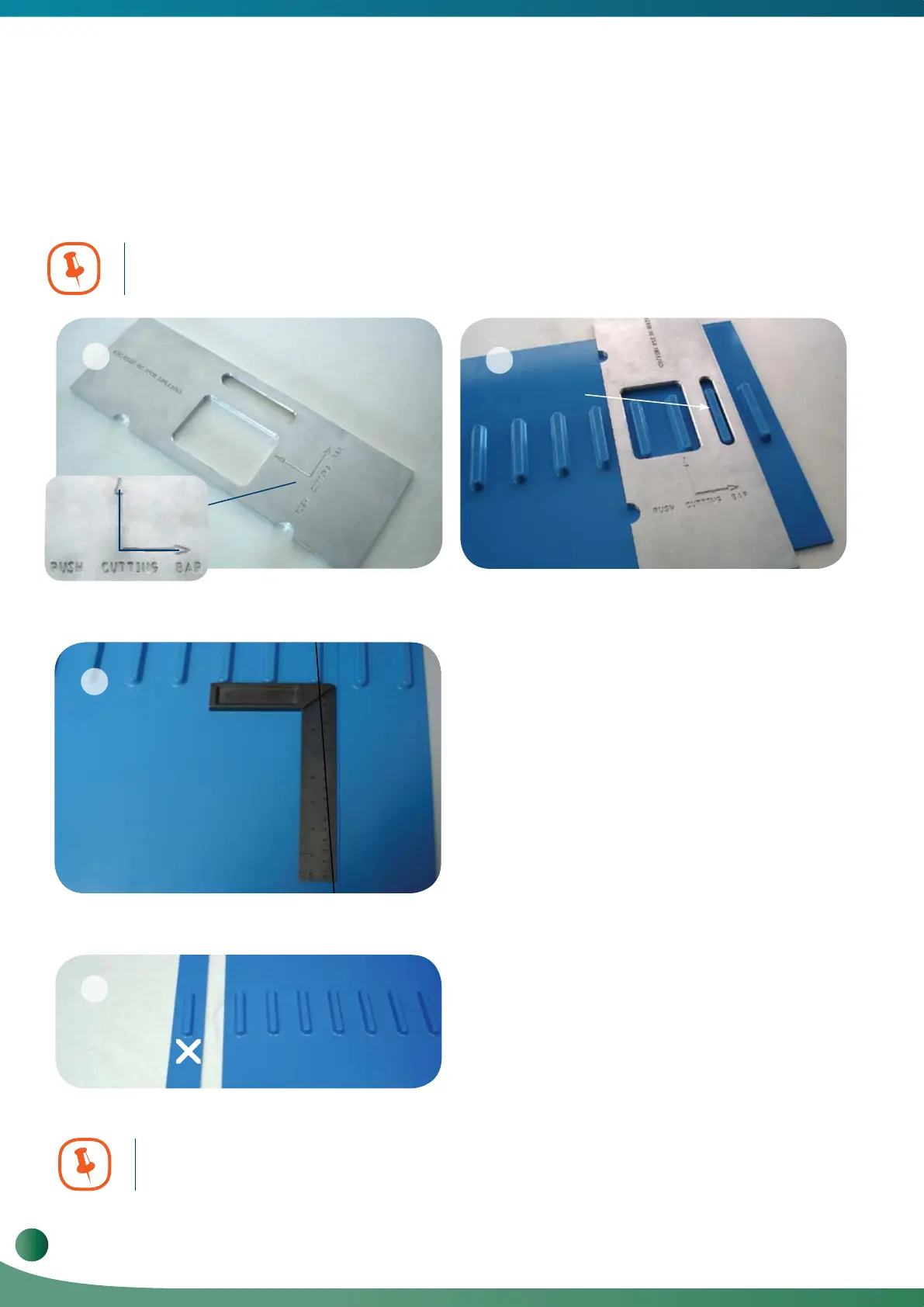

No Gap

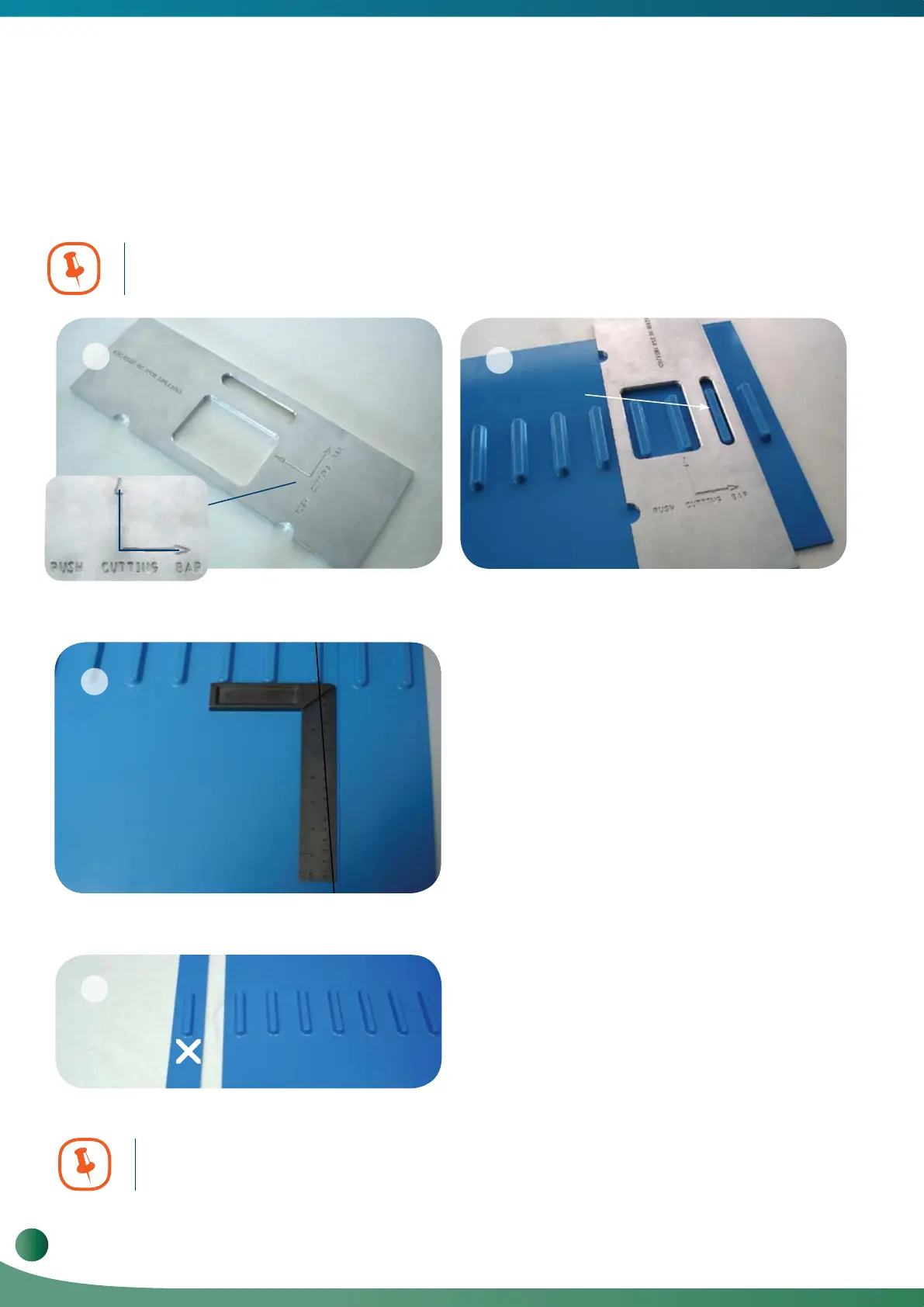

PUSH CUTTING BAR

8. Welding Positive Drive Belts

8.1. Instructions for Welding SuperDrive™ H/M Material Belts

Using FBW-301, FBW-721, FBW-1061 or FBW-1301.

It is Essential to carry out several welding trails to become familiar with welding the

Positive Drive conveyor belts.

1.

a.

b.

Tip. Use double sided tape on the bottom side of the cutting bar to prevent

slippage while cutting.

Reposition the cutting bar make a clean cut using a

sharp knife. When cutting the SD, we will have 2

ends one usable and one unusable (Photo 4, 5, 6)

this is due to the fact that we did not cut in the middle

of the pitch.

Use the Cutting Bar to cut the belt between the teeth,

to ensure a 90º cut and the correct pitch. Push the

cutting bar away from you and then against the right

side until the single tooth stencil fits exactly in line with

the tooth, giving you a perfect 90º position for marking

your line.Draw a line and then check that the line is

parallel to the teeth. Photo’s 2 & 3. When cutting the

belt this line will help us to make sure that the cut is

square.

The cutting bar is marked with positioning arrows as

per photo 1.

1

3

2

4

20

Volta Belting Technology Ltd.

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

Loading...

Loading...