4.4. Welding Cresent top (CT)

Required Tools:

You must be familiar with the instructions for welding with FBW before continuing

with this procedure.

FBW Welding Kit

CT Cutting Bar for all FBW welding tool sizes Cat. # 81626365

Wood Chisel 6 mm (¼”)

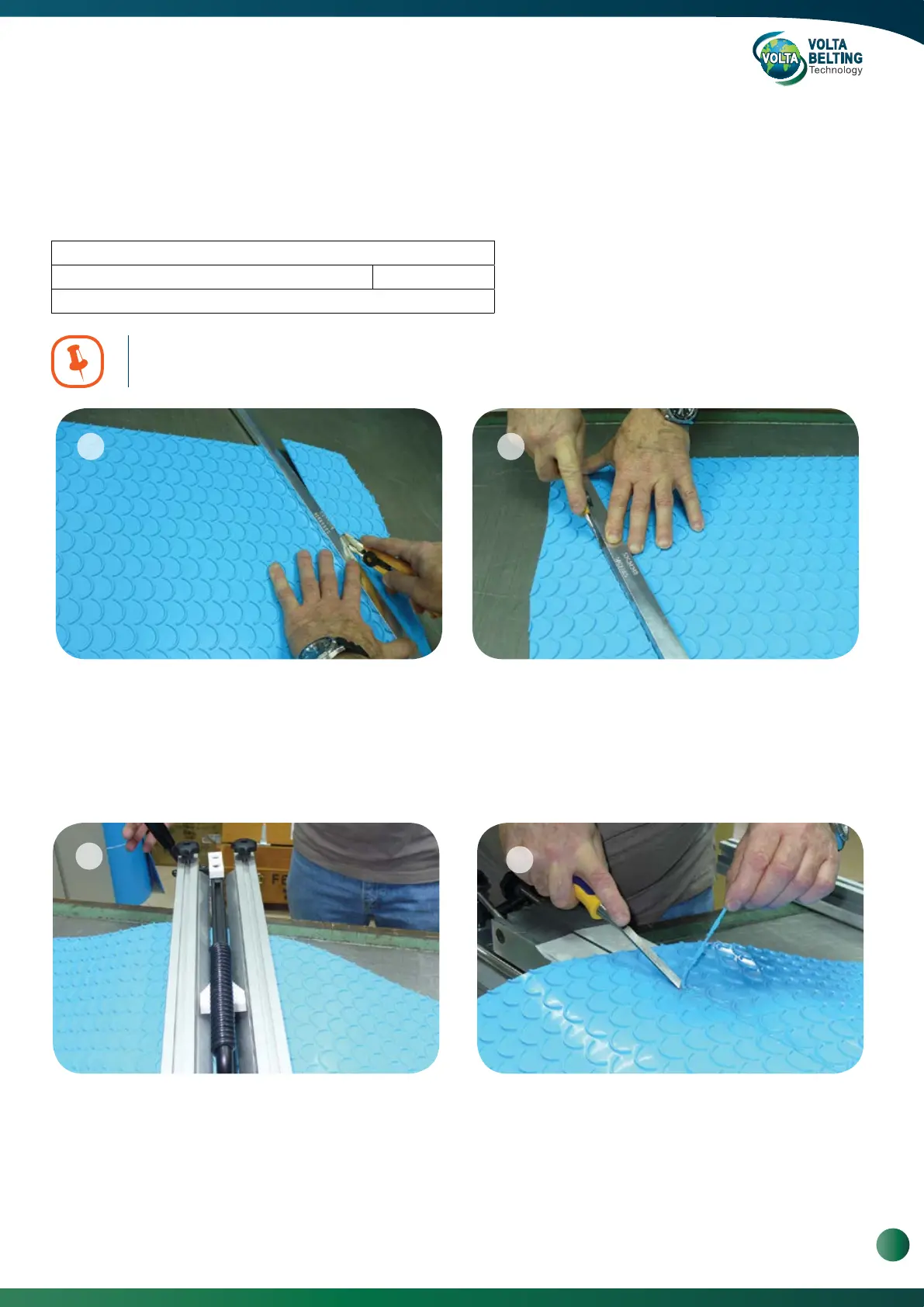

Go to the other side of the belt and insert the Cutting Bar

as close to the required size. Make sure that the scrap and

the “Cutting” engraving (on the bar) are on your right-hand

side. To carry out this step, please stand on the opposite

side of the belt. Add or deduct from the length of the belt

according to the position of the pattern.

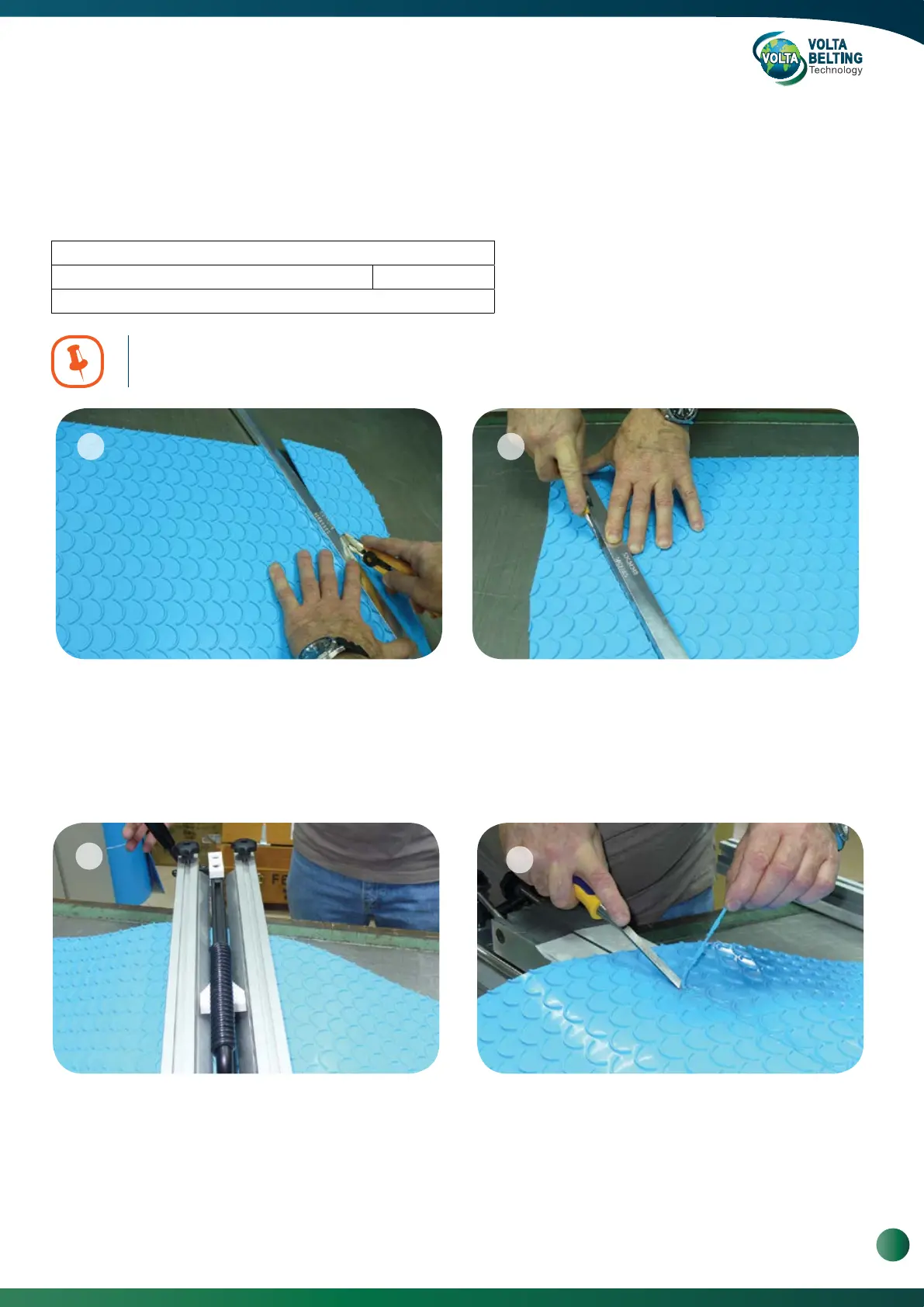

Place the belt with the pattern facing to the left as shown

in the picture. Insert the Cutting Bar at an angle between

the patterns when the “Cutting” engraving (on the bar) and

the belt scrap is on the right-hand side. Cut the belt with a

sharp knife. If the belt is wider than the adapter, cut the

belt in two steps.

The weld is performed at an angle alongside the crescent pattern. There will be a 20 mm difference on the final length of

the belt according to the cutting line between the patterns.

1 2

21

22

Weld the belt according to the instructions as described

in the FBW Intruction Manual (Page 13). When welding

belts made of L material, be careful and use less

pressure during the melting process and tightening after

melting.

After cooling the belt, trim the weld with a wood chisel

when the flat side is facing the belt. Use liquid soap to

improve the cut if required. Turn the belt and trim the

bottom weld as usual. Check the weld and perform

“cosmetic” finish if necessary. A good weld will be free of

cracks and defects.

4

3

17

www.voltabelting.com

Loading...

Loading...