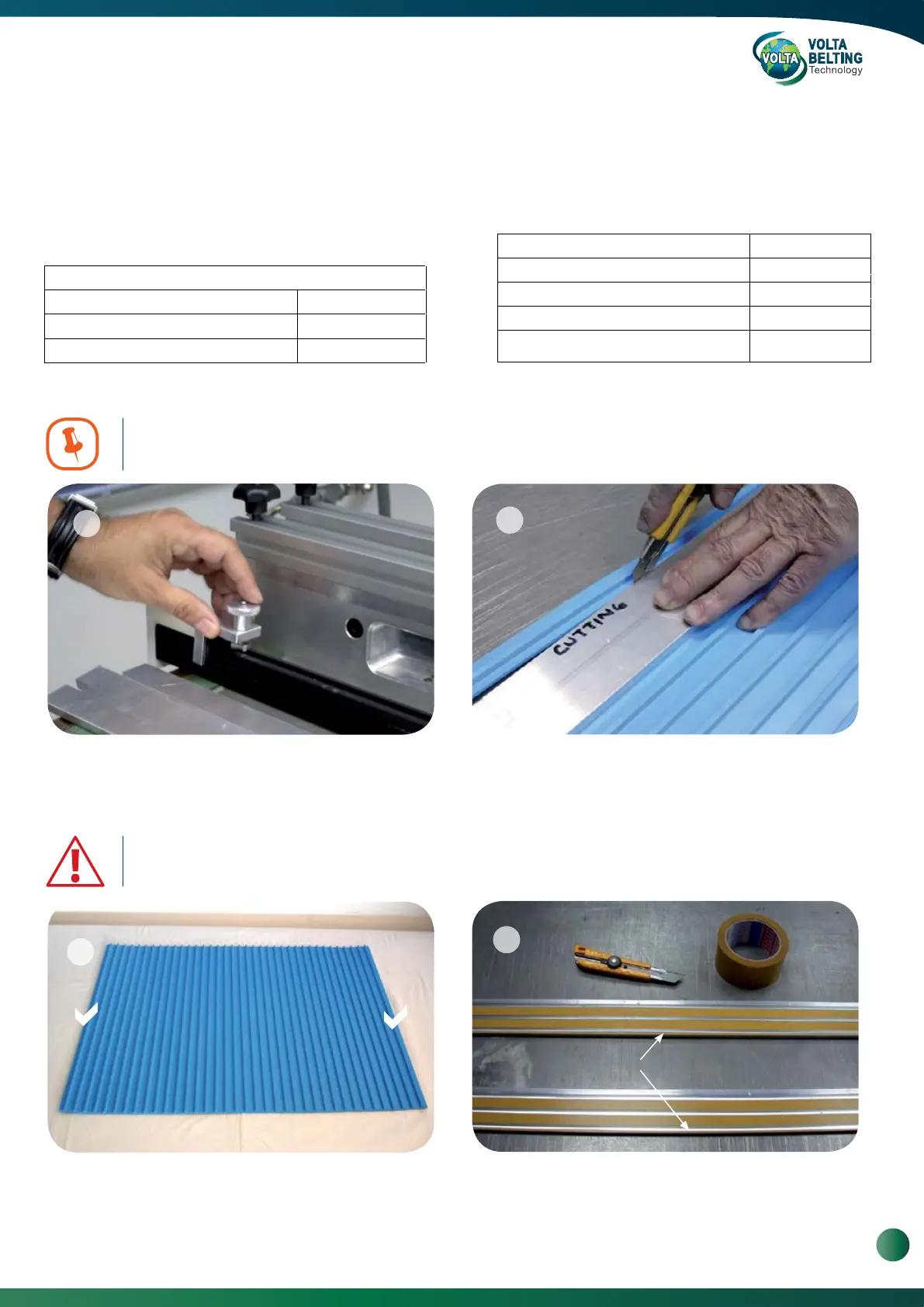

To keep the correct pitch, place the stopper on the

welder. Loosen the screws of the Stoppers and place

them in the groove on the end sides of the Welder. Tightly

secure the screws.

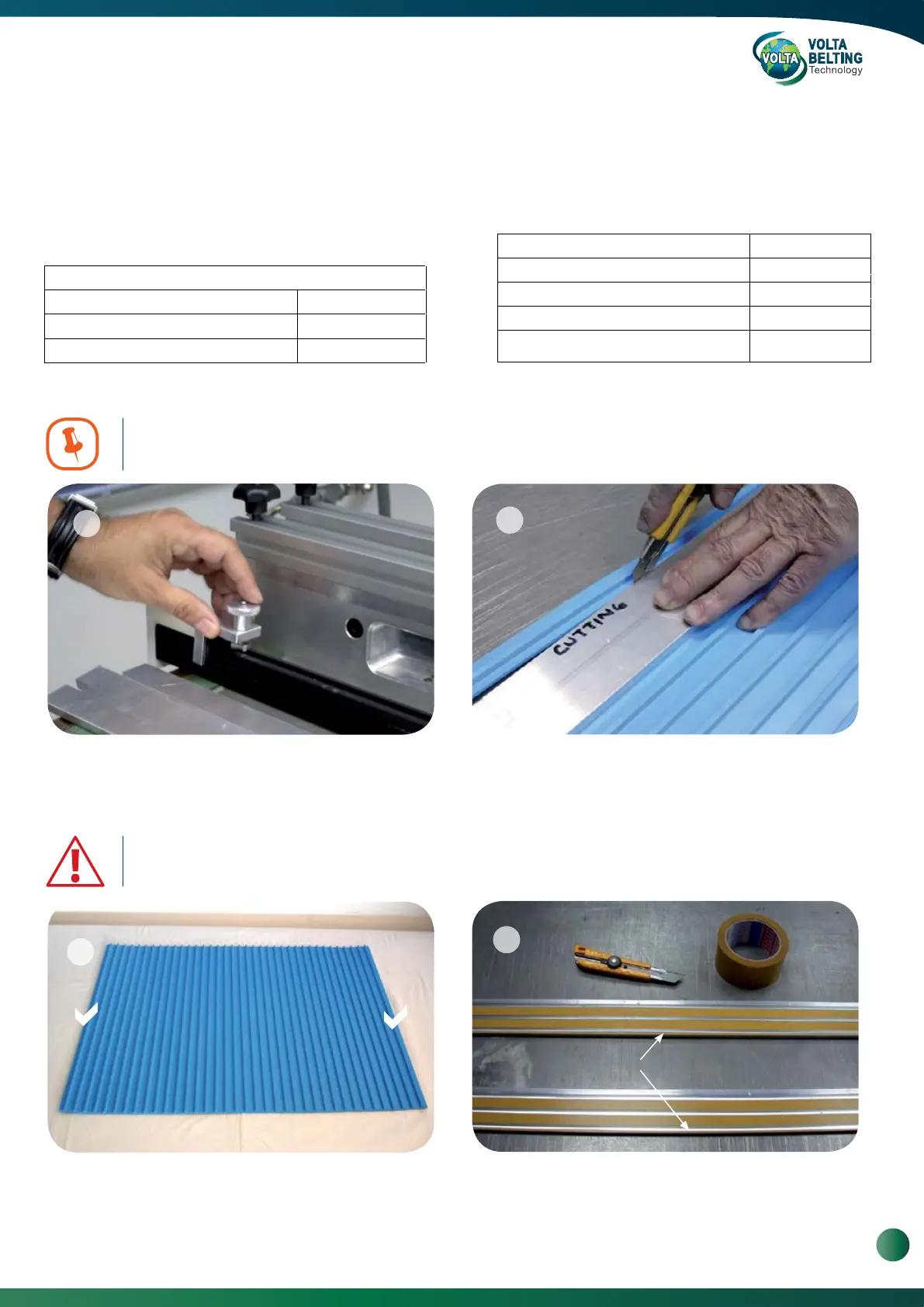

Heat up the Welder. Choose the DualDrive

TM

SP Adapter

that fits to the Pliers (see Required Tools above). Cut the

two ends of the belt along the side marked Cutting.

Ensure that the cut is accurate and straight.

Apply strips of good quality Double-Sided Tape on the

Adapters on the grooved surfaces from the narrow side

inwards. Trim the unnecessary tape from the grooves.

To ensure an accurate and efficient weld of DualDrive

TM

SP belts, use FBW DualDrive

TM

SP Adapter Kit. If you haven’t welded this

product before, weld a section of a trial belt before welding your Volta conveyor belt.

* For welding DD SP Lace follow the same instructions as seen on pages 24-25.

narrow side

8.7.

Welding DualDrive™ SP (DDSP) Belts and DDSP Lace

Required Tools:

FBW Welding Kit

DDSP Adapter Set for FBW - 301 Cat. #81626317

DDSP Adapter Set for FBW - 721 Cat. #81626327

DDSP Adapter Set for FBW - 1061 Cat. #81626332

* Non-standard

** Positioner for welder FBW - 1301 and FBW - 1701 only.

Instructions on Page 22.

DDSP Adapter Set for FBW - 1301* Cat. #81626337

Stoppers (2 units) Cat. #81626340

V Trim Knife Narrow Cat. #8153108

Utility Knife

Positioner for welder** Cat. #81626342

Do not assemble/disassemble stoppers when welder is hot.

You must be familiar with the instructions for welding with FBW before

continuing with this procedure.

1

2

4

3

29

www.voltabelting.com

Loading...

Loading...