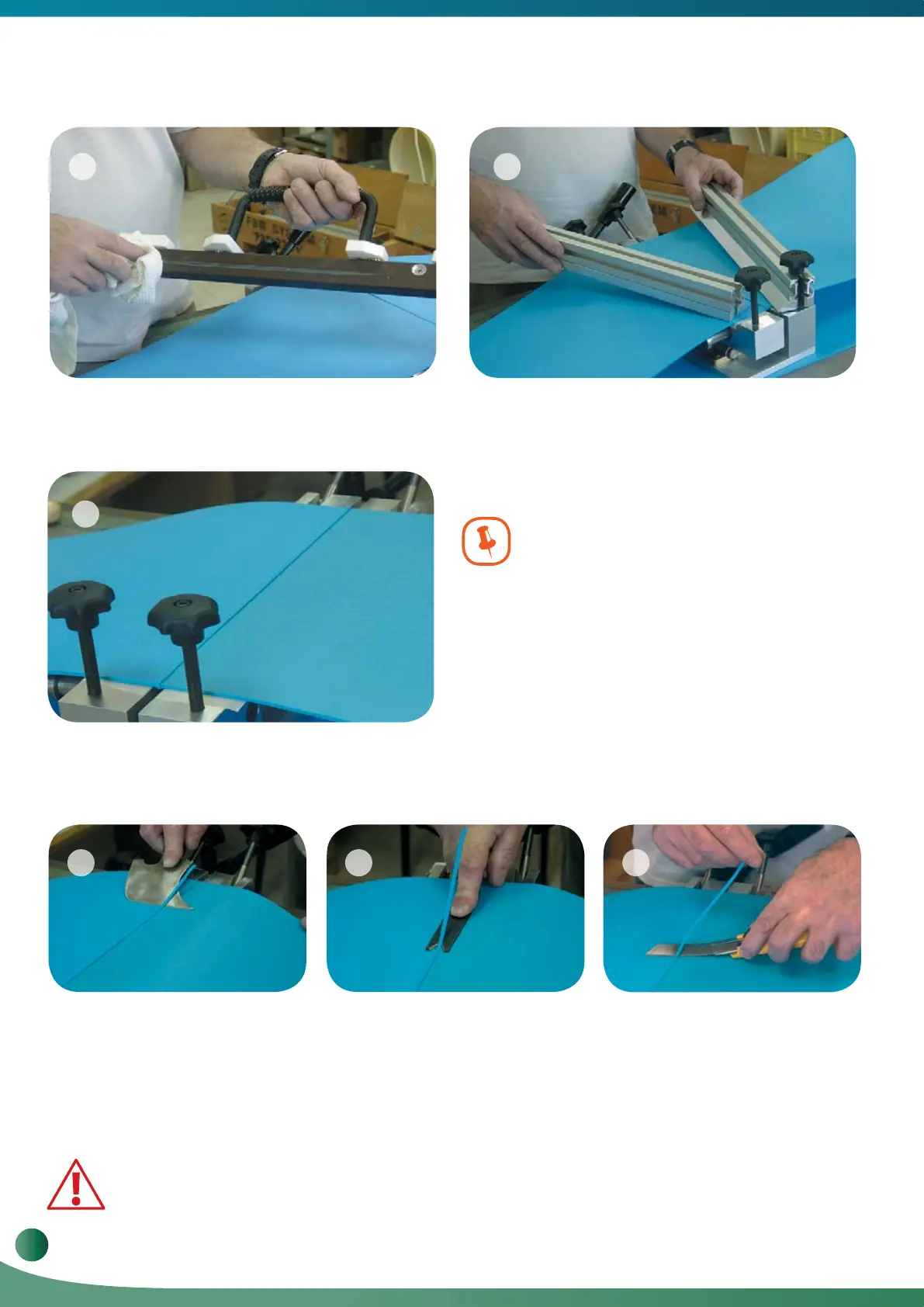

Clean the Welder using a clean, dry, lint-free soft Cotton

cloth while the Welder is hot. Leaving material on the

Welder will damage the Welders surface and reduce the

efficiency of the Welder and the quality of the welds.

Separate the belt from the Pliers and turn it over placing

the trimmed surface on the Pliers. Trim the excess from

the bottom of the belt.

Check the splice quality by bending the belt in both

directions. Check the quality of the splice across the

width of the belt and on both sides. A good weld will be

free of cracks and defects. In case of a bad splice repeat

the above steps (this will cause the loss of about 5 mm

of the belt’s length).

The amount of pressure required to secure the ends of the

belt depends on the thickness and type of material being

welded.

During welding, air bubbles are formed in the melted ends.

The bubbles should be pressed out during the operation.

If too much pressure is applied during welding, the heat will

penetrate only a very narrow section along the edge of the

belt. When the Pliers are closed this small amount of melted

material will be pushed out. To ensure a quality weld, the

heat must penetrate a wide section of the belt.

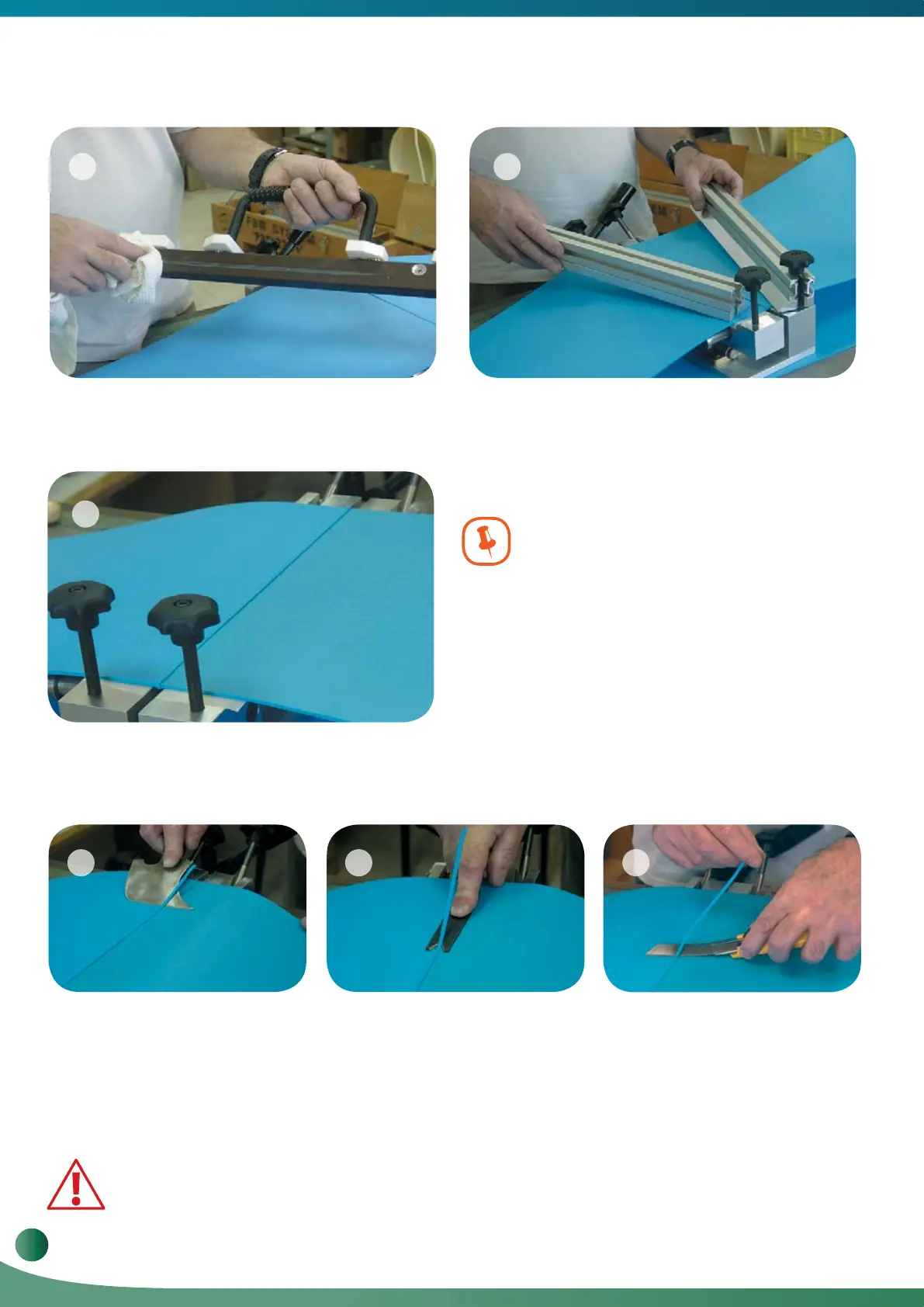

Using Leister Knife to trim

excess from weld

Using V-trimmer to trim

excess from weld

Using Utility knife to trim

excess from weld

e.

f. When the belt is cooled, leave the Pliers closed and

remove the two Crossbars.

g. Welded belt with excess.

3.5. Trimming and Checking the Weld

a.

Using a Leister Knife or other appropriate tool, trim the excess from the top of the belt.

c.

b.

The following factors must be kept in mind

when welding:

•

•

•

15 16

17

18 19 20

Use a finger guard when engaging in various activities that involve the use

of sharp objects. Handle the knife with care. Cut away from your body, not toward it.

12

Volta Belting Technology Ltd.

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

Loading...

Loading...