46

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

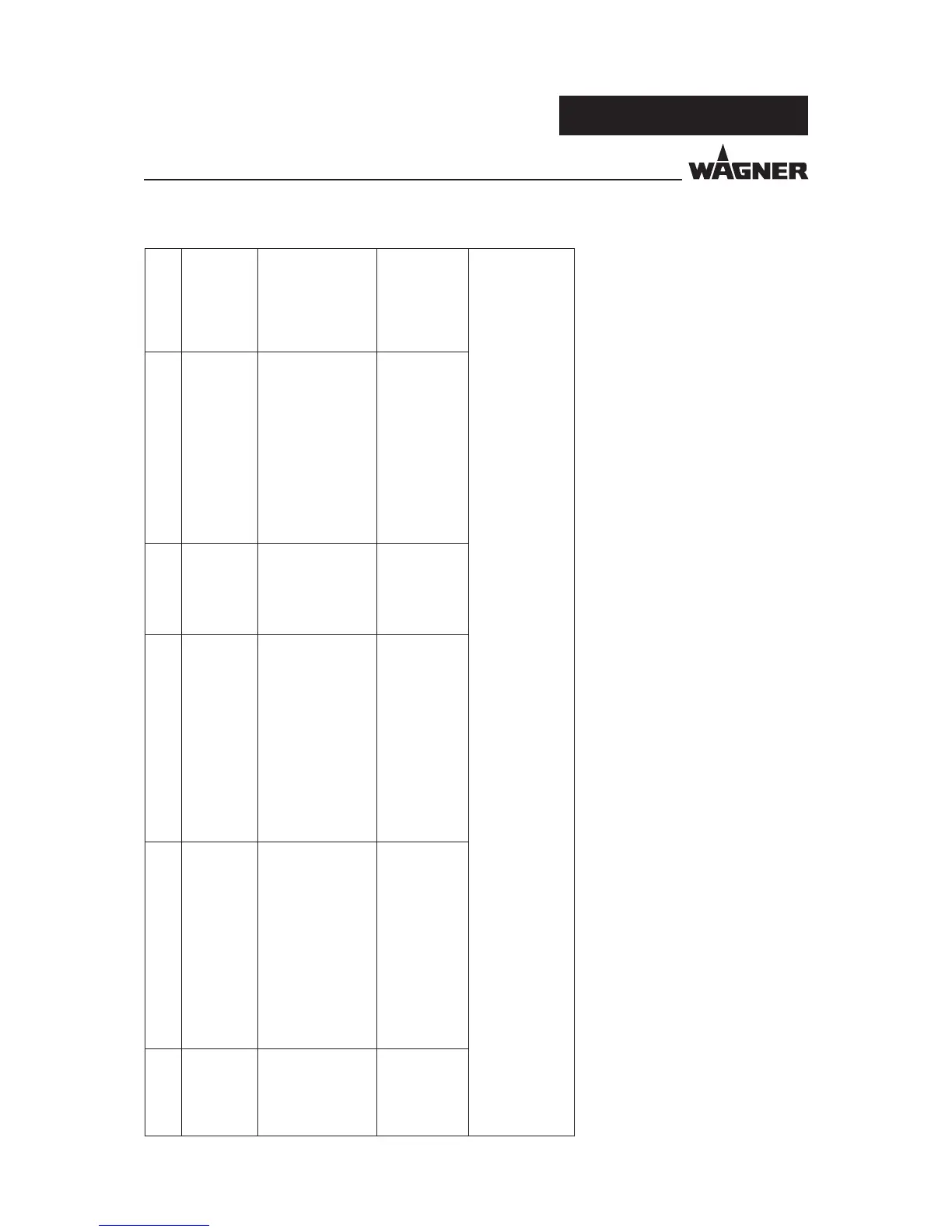

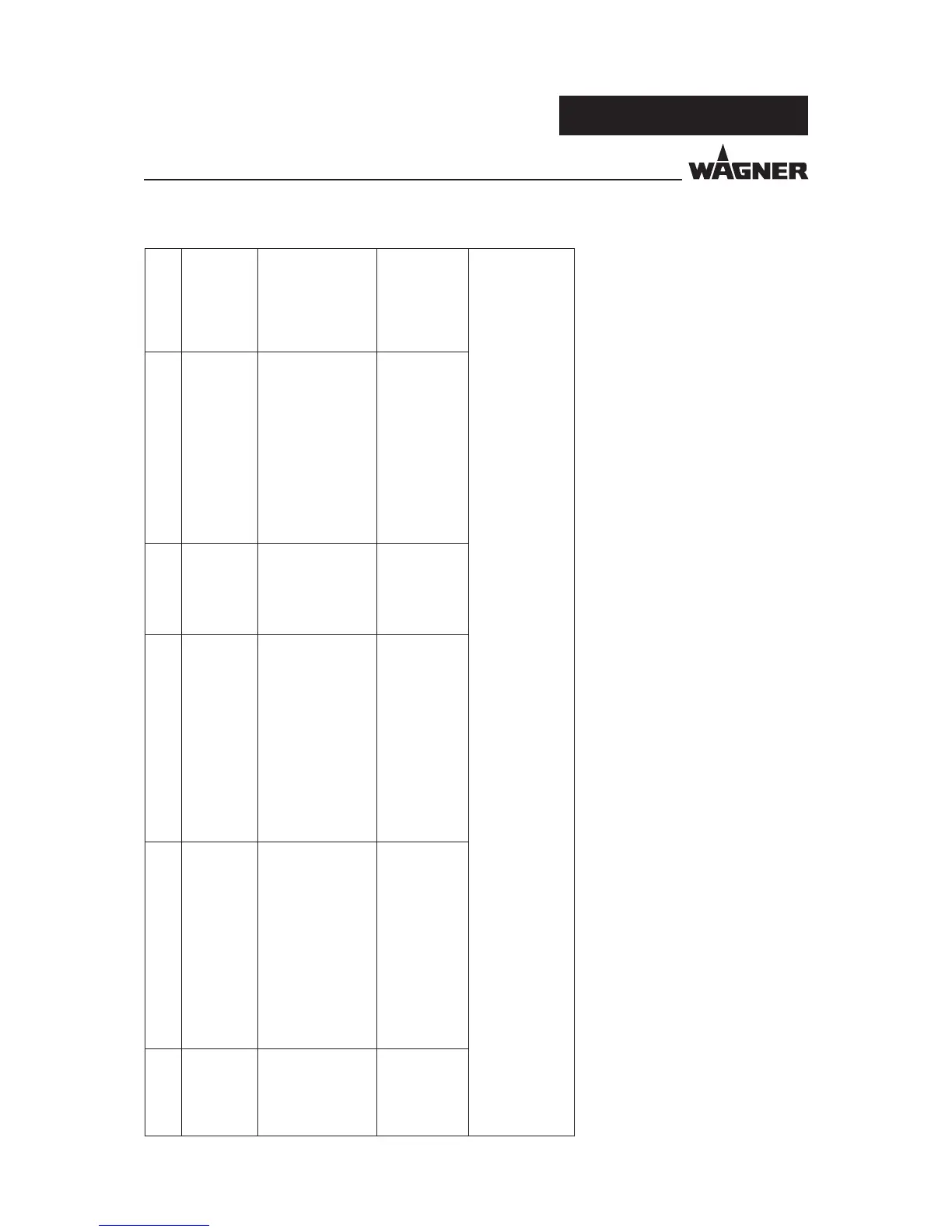

Section Type of inspection Requirements Inspection

by

Type of inspection Inspection

interval

1 Checking the e ectiveness of

technical ventilation

Checking the e ectiveness of

technical ventilation

TP/SP

ME

Measurements of air ow speed/

air quantities

Check the di erential pressure

indicator

continuously

2 Link between technical ventilation

equipment and high voltage,

compressed air and coating

material supply

The technical ventilation should

be interlocked such that the

powder feed and high voltage

cannot be switched on, while the

technical ventilation is not working

e ectively.

SP

FI

Test whether the system is safely

stopped and the product supply,

supply air, and high voltage

are switched o when the

ventilation is shut down.

annually

3 Parts carrying high voltage outside

the spray area

Parts carrying high voltage outside

the spray area must be routed such

that discharges which put people at

risk do not occur.

SP

FI

Inspect and test (e.g., by

measurement) whether all parts

carrying high voltage do not

result in discharge which puts

people at risk.

weekly

Legend:

MF = Manufacturer

ER = Employer

SP = Skilled person

FPO = Fire prevention o cer

ELT = Electrician

TP = Trained person

FI = Function inspection

ME = Measurement

OC = Organization check

VI = Visual inspection

CM = Constant monitoring

TT = Technical testing

Loading...

Loading...