33

VERSION 05/2019

ORDER NUMBER DOC2326960

PEM-X1 CG

7.4 OPTIMIZING THE POWDER CLOUD FOR COATING

Procedure:

1. Switch on the high-voltage generation and the powder feed.

Note:

To minimize wear on the wearing parts, the total air volume should be below 5 Nm³/h.

The atomizing air should be adjusted for the

– at jet nozzle to 0.1 Nm³/h

– round jet nozzle to > 0.2 Nm³/h

2. Adjust the powder quantity and the powder speed on a test piece.

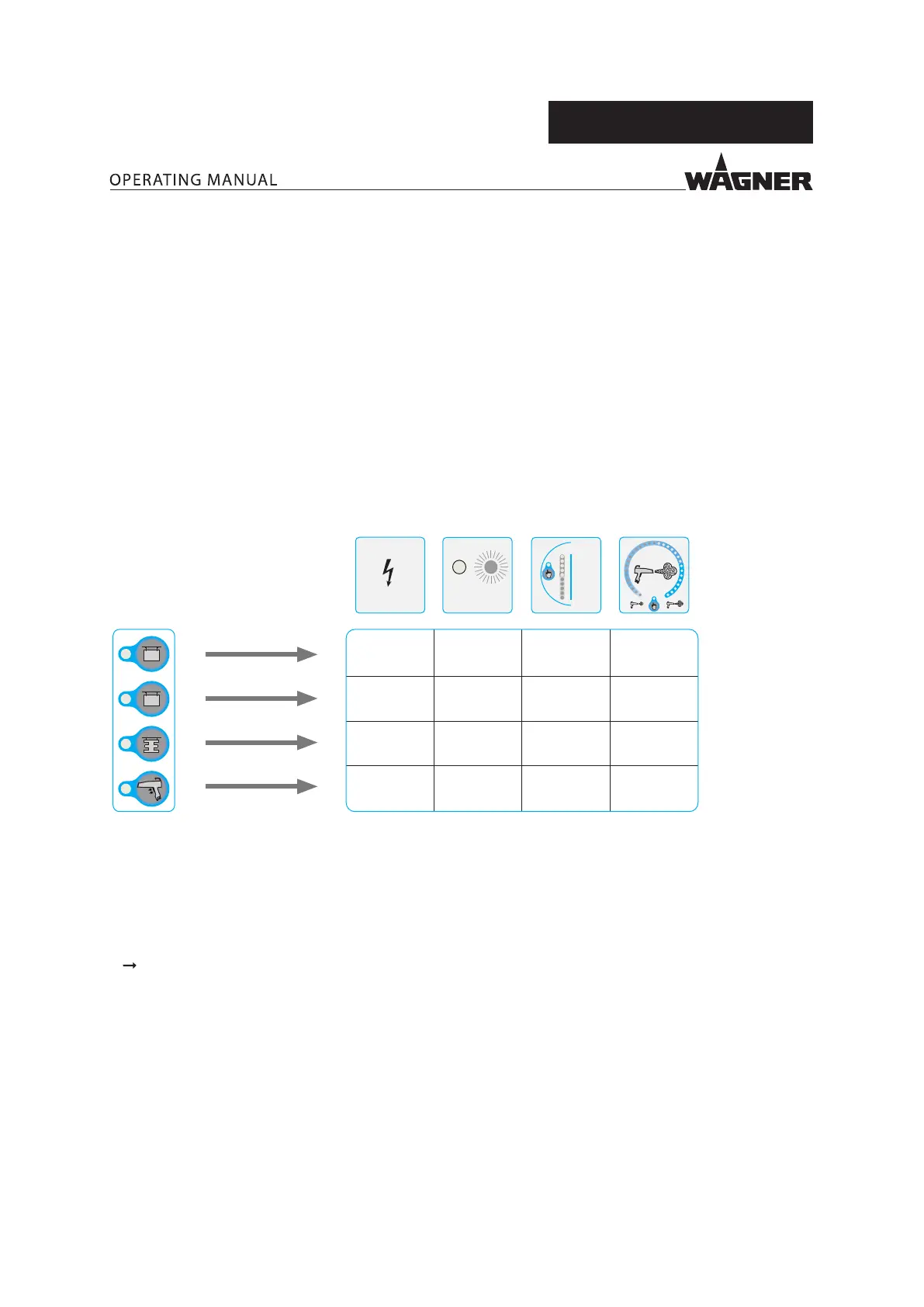

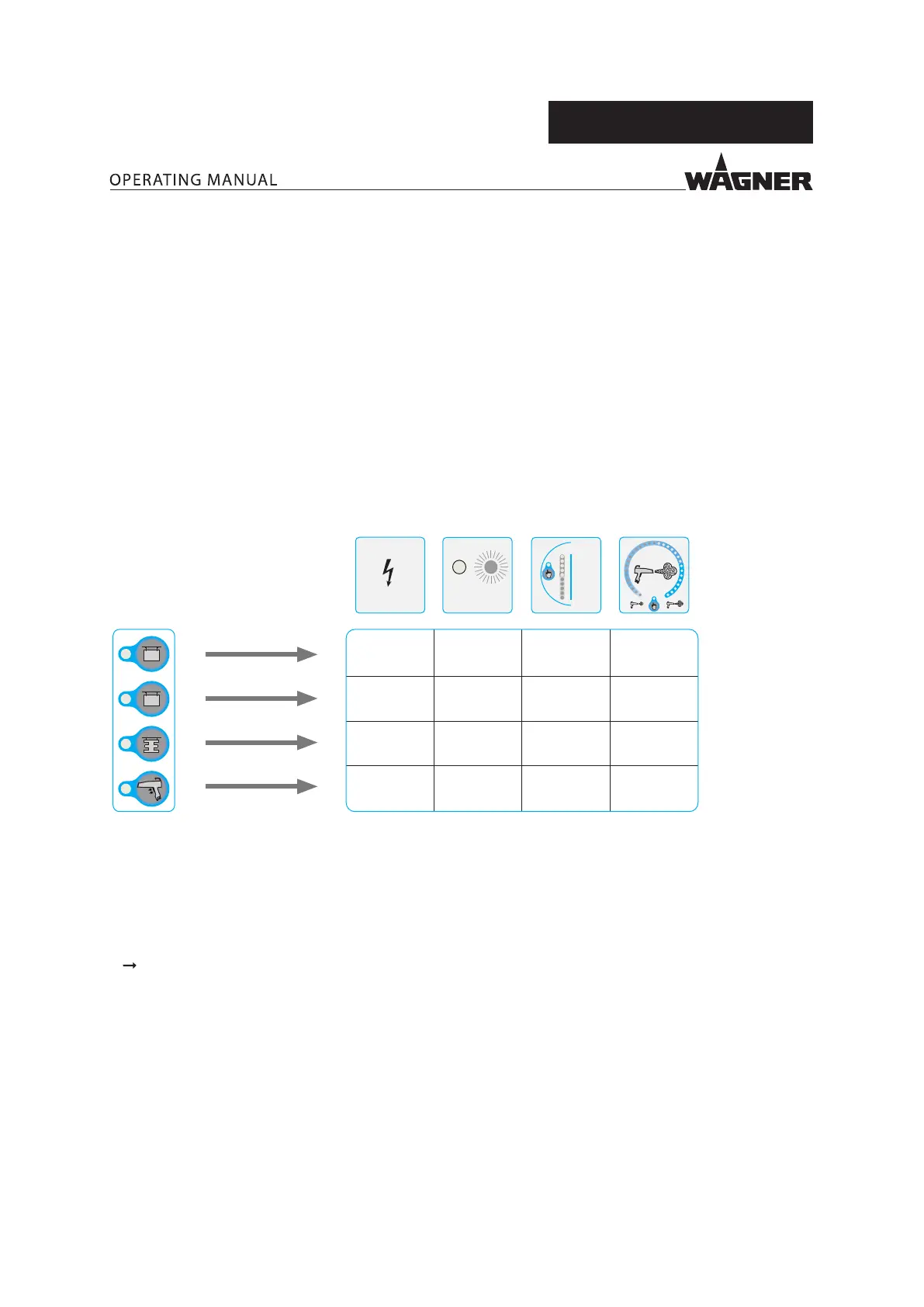

7.4.1 RECOMMENDED SETTINGS FOR TOTAL AIR VOLUME

2x

2x

Tribo Corona

Ø

12

10

11

9

8

m /h

2.0

3

5.5

4.5

3.5

2.5

0 %

100 %

10

20

30

40

50

60

70

80

90

[µA] [Nm³/h] [%][kV]

90 80 2.0 50

50 30 1.5 40

60 40 1.2 40

P_01828

82 20 1.8 30

7.5 SWITCHING OFF THE CUP GUN

When releasing the trigger, the powder feed is stopped and the high voltage switched o.

To safely switch o the cup gun, e.g., for maintenance work, the control unit must be switched o.

7.5.1 PRESSURE RELIEF/WORK INTERRUPTION

Carry out the work steps as described in the "Pressure relief" chapter:

– if pressure relief is required,

– if the coating work is interrupted or stopped,

– before the device is cleaned on the outside, checked, or serviced,

– before the spray nozzle is installed or cleaned.

Loading...

Loading...