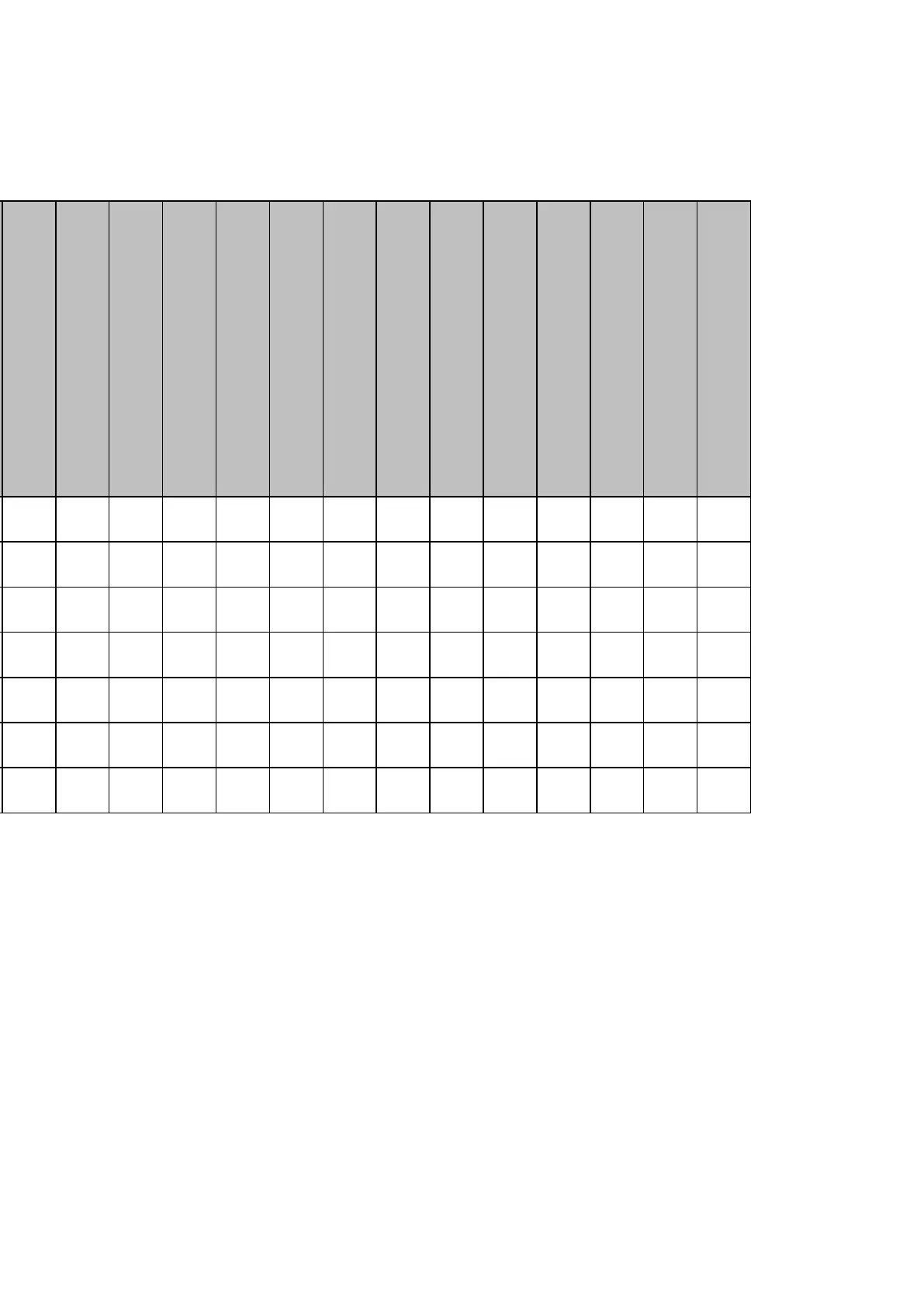

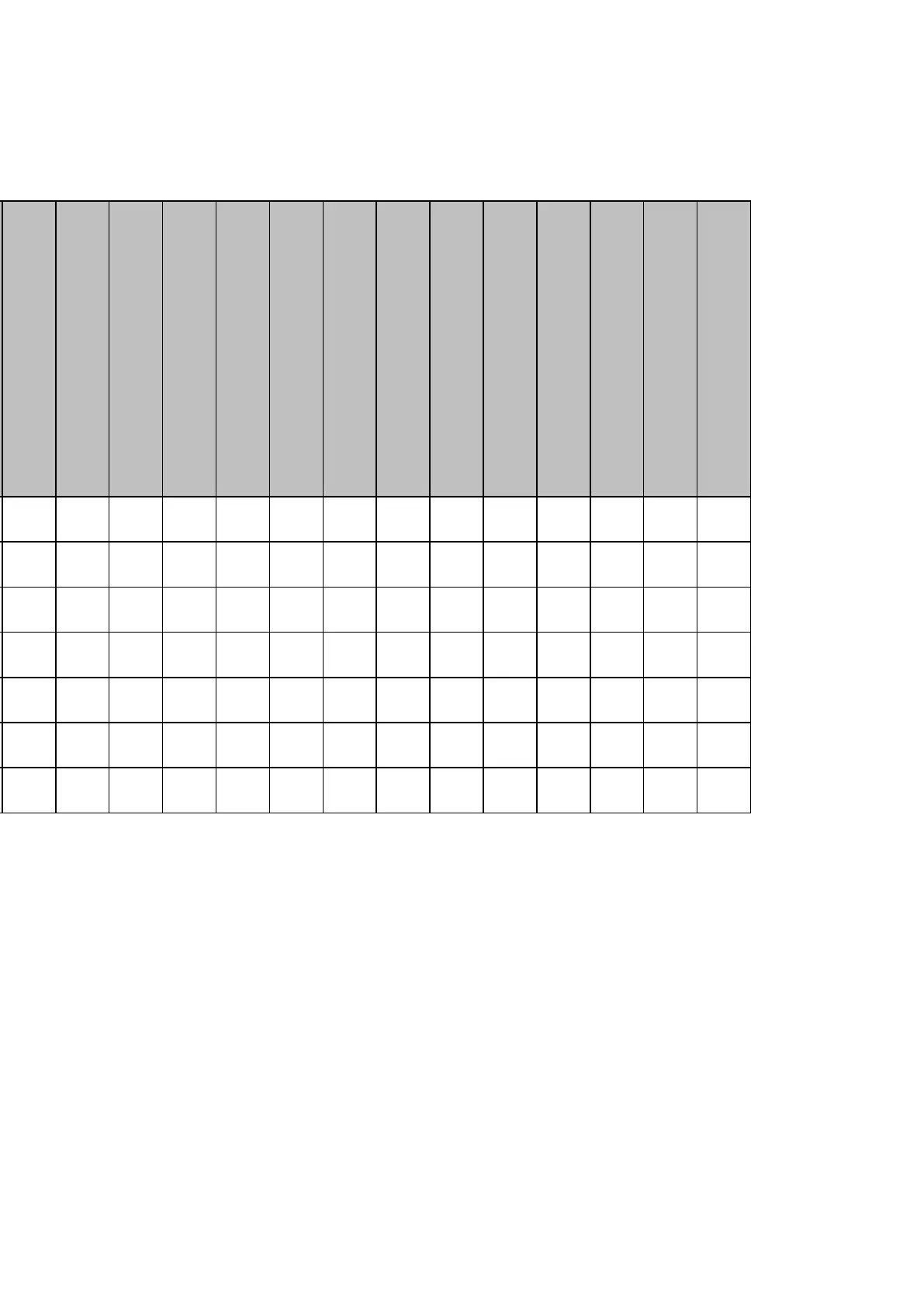

37

Activity

Check for visible damage, leaks, etc.

Check the control and safety devices for

proper operation

Check threaded unions an hoses for

leaks, tighten threaded unions

Check hydraulic oil level

Check engine oil level

Check coolant level in the expansion

reservoir and in the radiator

Check the charging status of the trans-

mier

Check the air lter. Clean, if necessary

Check all threaded unions for rm seat

Clean the water / hydraulic oil radiator

from the outside

Check and drain the water separator

Change engine oil and engine oil lter

Check condion and tension of the Fan

V-belt. Adjust if necessary

Check engine support and aachments

for rm seat

Check the cooling system for rm seat

Lubricate the arculated joint

Lubricate the drum bearings

Lubricate the cylinder

Replace air lter

Change fuel lter

Lightly oil all bare parts

Check joints and moving parts for

smooth operaon

Change the engine V-belt

Clean the diesel tank

Change hydraulic oil and lter

Change coolant (or every 2 years)

Check injecon nozzles

Interval

Initial maintenance /

25 operating hrs

X X X

Daily maintenance

X X X X X X X X

Every 50 operating

hrs

X X X

Every 150 operating

hrs

X X X X X X X X X X X

Every 300 operating

hrs

X X X X X X X X X X X X X X

Every 600 operating

hrs

X X X X X X X X X X X X X X X X X X X

See section 10.2.3 10.2.3 10.2.3 6.3 10.2.6 10.2.7

10.2.4

10.2.5

10.2.12 10.2.1410.2.1410.2.14 10.2.6 10.2.8 10.2.13 Kubota

10.2.9

10.2.10

Kubota

Loading...

Loading...