STARTING/STOPPING

PROCEDURE

THE

STARTING

SYSTEM

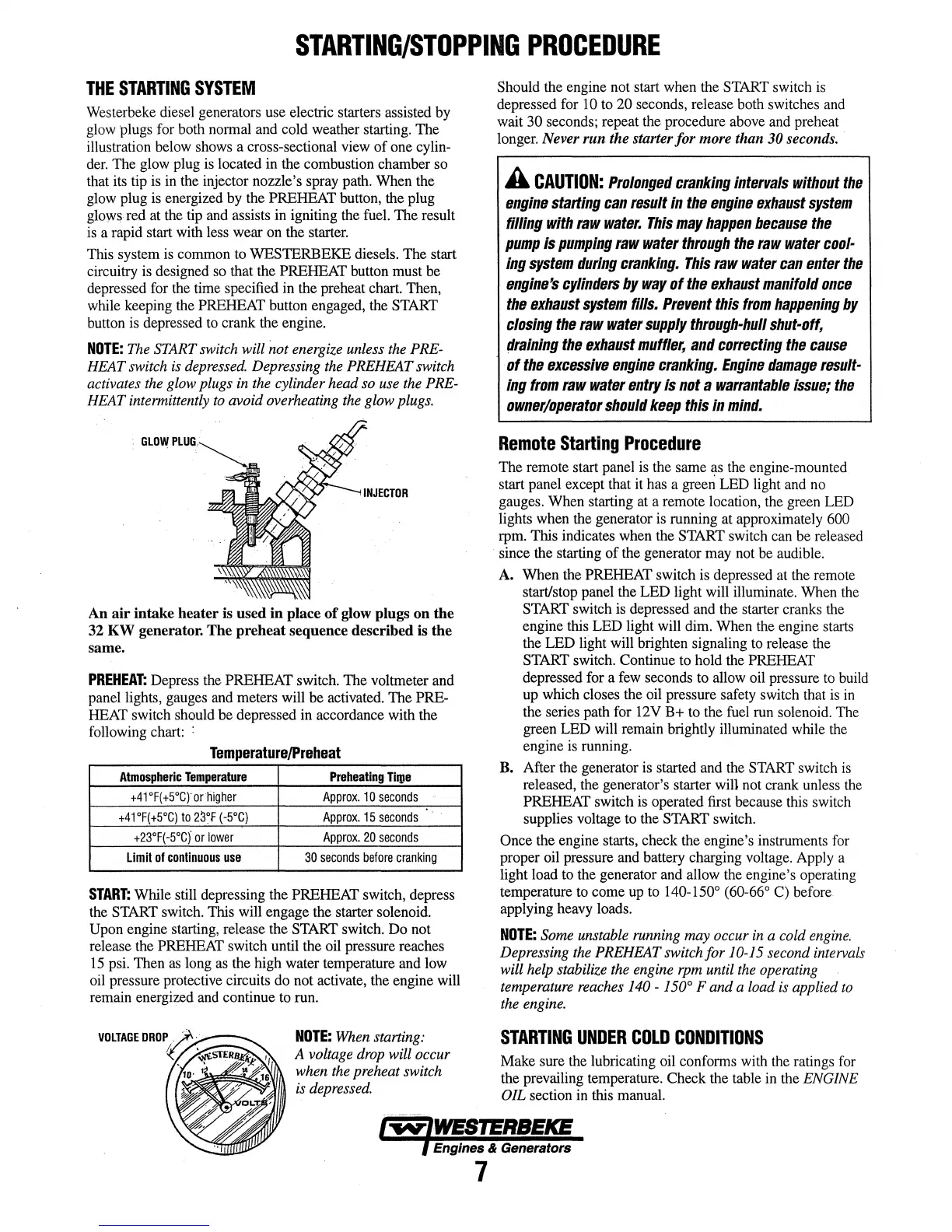

Westerbeke

diesel

generators

use

electric starters assisted

by

glow

plugs

for

both nonnal

and

cold weather starting. The

illustration

below

shows

a cross-sectional

view

of one cylin-

der.

The

glow

plug

is

located

in

the combustion chamber

so

that

its

tip

is

in

the

injector nozzle's spray

path.

When

the

glow

plug

is

energized

by

the

PREHEAT

button,

the

plug

glows

red

at

the

tip

and

assists in igniting the

fuel.

The result

is

a rapid start

with

less

wear

on

the

starter.

This

system

is

common

to

WES1ERBEKE diesels. The start

circuitry

is

designed

so

that the

PREHEAT

button must

be

depressed

for

the

time

specified in the preheat

chart.

Then,

while

keeping

the

PREHEAT

button engaged, the

START

button

is

depressed

to

crank the engine.

NOTE:

The

START switch will not

energize

unless

the

PRE-

HEAT

switch

is

depressed.

Depressing

the

PREHEAT switch

activates

the

glow

plugs

in

the

cylinder head

so

use

the

PRE-

HEAT intermittently

to

avoid overheating

the

glow

plugs.

•

GLOW

An

air

intake

heater

is

used

in

place

of

glow pings

on

the

32

KW

generator.

The

preheat

sequence described is

the

same.

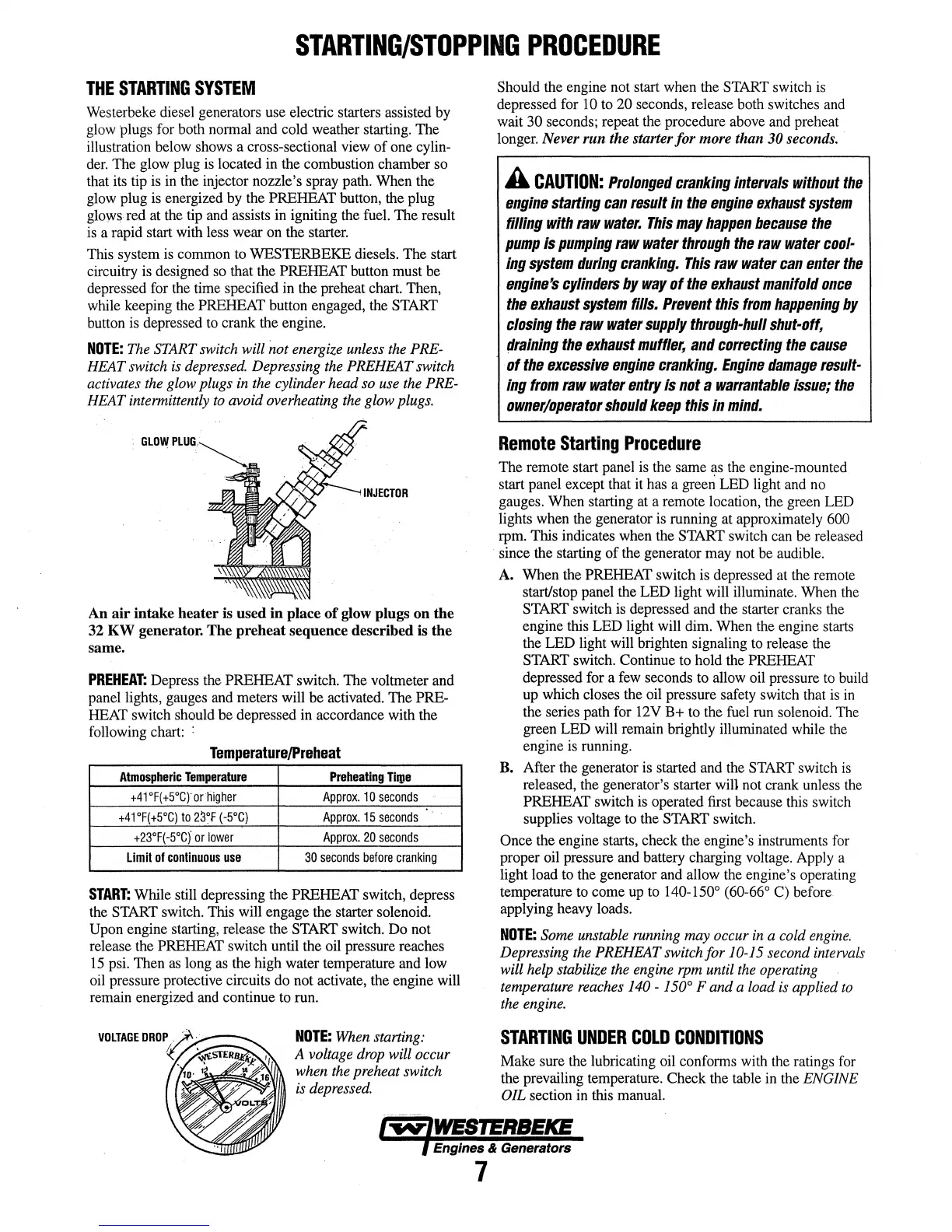

PREHEAT:

Depress the

PREHEAT

switch. The voltmeter and

panel lights,

gauges

and

meters

will

be activated. The

PRE-

HEAT

switch should be depressed

in

accordance with the

following

chart:

:

Temperature/Preheat

Atmospheric

Temperature

Preheating

Tillie

+41

•f(

+5"C).

or

higher

Approx.

10

seconds

+41"F(

+5.C)

to

23~f

(

-s·c)

Approx.

15

seconds

+23.F(-5"Cf

or

lower

Approx.

20

seconds

Limit

of

continuous

use

30

seconds

before

cranking

START:

While still depressing the

PREHEAT

switch, depress

the

START

switch.

This

will

engage the starter solenoid.

Upon

engine starting, release the

START

switch.

Do

not

release the

PREHEAT

switch until the oil pressure reaches

15

psi.

Then

as

long

as

the high water temperature

and

low

oil

pressure protective circuits

do

not

activate,

the engine

will

remain energized

and

continue

to

run.

NOTE:

When

starting:

A voltage

drop

will occur

when

the

preheat switch

is

depressed.

Should the engine

not

start

when

the

START

switch

is

depressed

for

10

to

20 seconds, release both switches

and

wait 30 seconds; repeat

the

procedure

above

and

preheat

longer.

Never run the starter for more than 30 seconds.

A

CAUTION:

Prolonged

cranking

Intervals

without

the

engine

starting

can

result

In

the

engine

exhaust

system

filling

with

raw

water.

This

may

happen

because

the

pump

Is

pumping

raw

water

through

the

raw

water

cool-

Ing

system

during

cranking.

This

raw

water

can

enter

the

engine's

cylinders

by

way

of

the

exhaust

manifold

once

the

exhaust

system

fills.

Prevent

this

from

happening

by

closing

the

raw

water

supply

through-hull

shut-off,

f/ralnlng

the

exhaust

muffler,

and

correcting

the

cause

of

the

excessive

engine

cranking.

Engine

damage

result-

Ing

from

raw

water

entry

Is

not

a

warrantable

Issue;

the

owner/operator

should

keep

this

In

mind.

Remote

Starting

Procedure

The remote start

panel

is

the same

~s

the

engine-mounted

start panel except that

it

has

a green

LED

light

and

no

gauges.

When

starting

at

a remote location, the green

LED

lights

when

the

generator

is

running

at

approximately

600

rpm.

This indicates

when

the

START

switch

can

be released

since

the

starting of the generator

may

not

be

audible.

A. When

the

PREHEAT

switch

is

depressed at

the

remote

start/stop panel the LED light

will

illuminate.

When

the

START

switch

is

depressed

and

the

starter cranks the

engine this LED light will

dim.

When

the engine

starts

the LED light will brighten signaling

to

release

the

START

switch.

Continue

to

hold the

PREHEAT

depressed for a

few

seconds to

allow

oil pressure

to

build

up which closes

the

oil

pressure safety switch that

is

in

the series path for

12V

B+

to

the

fuel

run

solenoid. The

green

LED

will

remain brightly illuminated

while

the

engine

is

running.

B.

After

the

generator

is

started and

the

START

switch

is

released, the generator's starter

will

not

crank

unless

the

PREHEAT switch is operated

first

because

this

switch

supplies voltage

to

the

START

switch.

Once the engine starts, check the engine's instruments

for

proper

oil

pressure

and

battery charging

voltage.

Apply

a

light load

to

the

generator

and

allow

the

engine's operating

temperature

to

come

up

to

140-150°

(60-66°

C)

before

applying

heavy

loads.

NOTE:

Some

unstable

running

may occur

in

a cold

engine.

Depressing

the

PREHEAT switch for 10-15 second

intervals

will help stabilize

the

engine

rpm

until

the

operating

temperature

reaches

140-

150° F

and

a

load

is

applied

to

the

engine.

STARTING

UNDER

COLD

CONDITIONS

Make sure

the

lubricating oil confonns with

the

ratings

for

the

prevailing temperature. Check

the

table

in

the

ENGINE

OIL section

in

this manual.

Engines & Generators

7

Loading...

Loading...