ENGINE

COOLING

CIRCUIT

DESCRIPTION

Westerbeke marine diesel generators are designed and

equipped for fresh water cooling. Heat produced in the

engine by combustion and friction is transferred

to

fresh

water coolant which circulates throughout the engine. This

circulating fresh water coolant cools the engine block and its

internal moving parts. The heat is transferred externally from

the fresh water coolant to raw water by means

of

a heat

exchanger, similar in function to an automotive radiator. Raw

water flows through the tubes

of

the heat exchanger while

fresh water coolant flows around the tubes; engine heat trans-

ferred to the fresh water coolant

is

conducted through the

tube walls to the raw water which is then pumped into the

exhaust system where finally

it

is discharged overboard. In

other

w~rds,

the engine

is

cooled by fresh water coolant, this

coolant

IS cooled by raw water, and the raw water carries the

transferred heat overboard through the exhaust system. The

fresh water coolant and raw water circuits are independent

of

each other. Using only fresh water coolant within the engine

allows the cooling water passages to stay clean and free from

harmful deposits.

Fresh

Water

Circuit

NOTE:

Refer to ENGINE COOLANT section for the recom-

mended antifreeze and water mixture to be used as the fresh

water coolant.

Fresh water coolant

is

pumped through the engine by a circu-

lating pump, absorbing heat from the engine. The coolant

then passes through the thermostat into the manifold, to the

heat exchanger where it

is

cooled and returned to the engine

block via the suction side

of

the circulating pump.

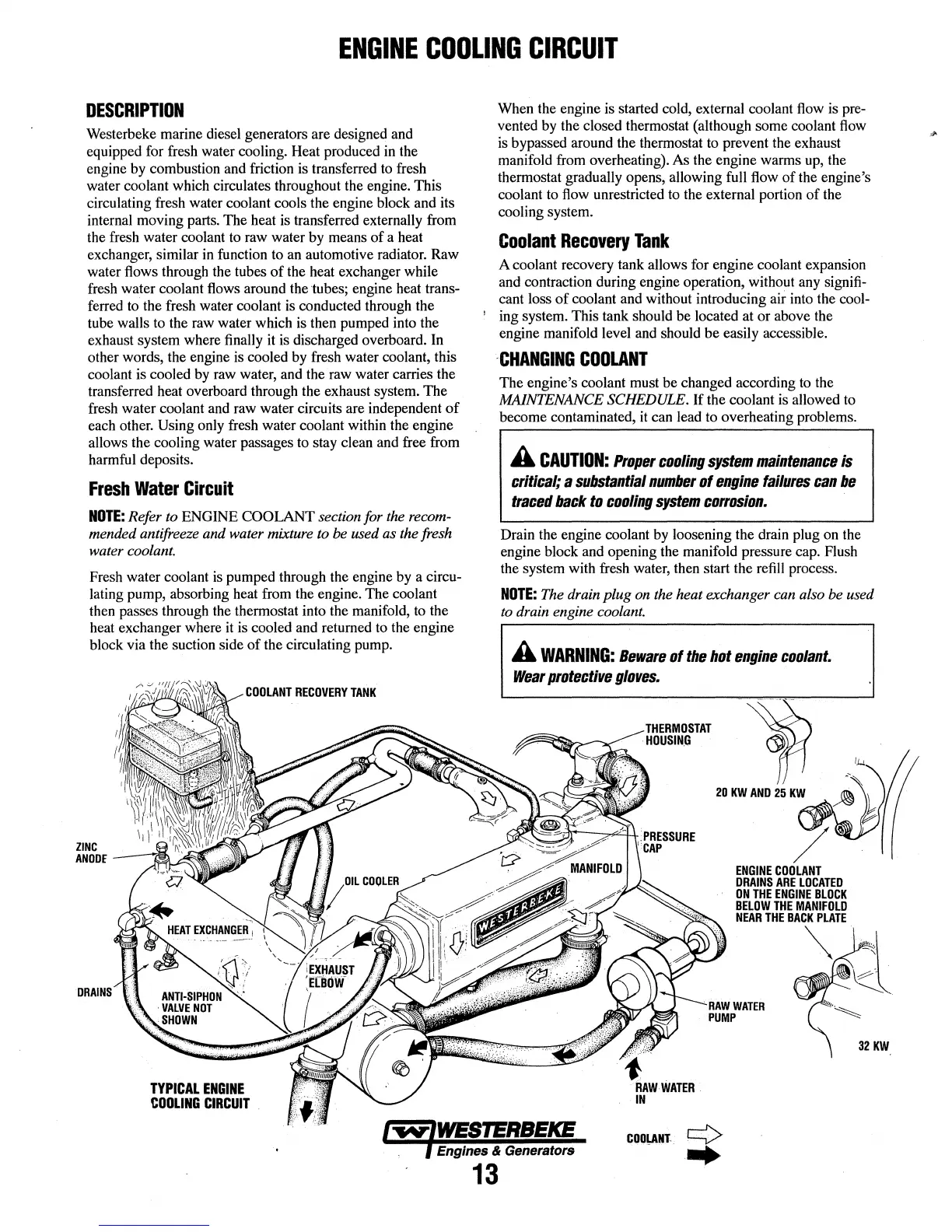

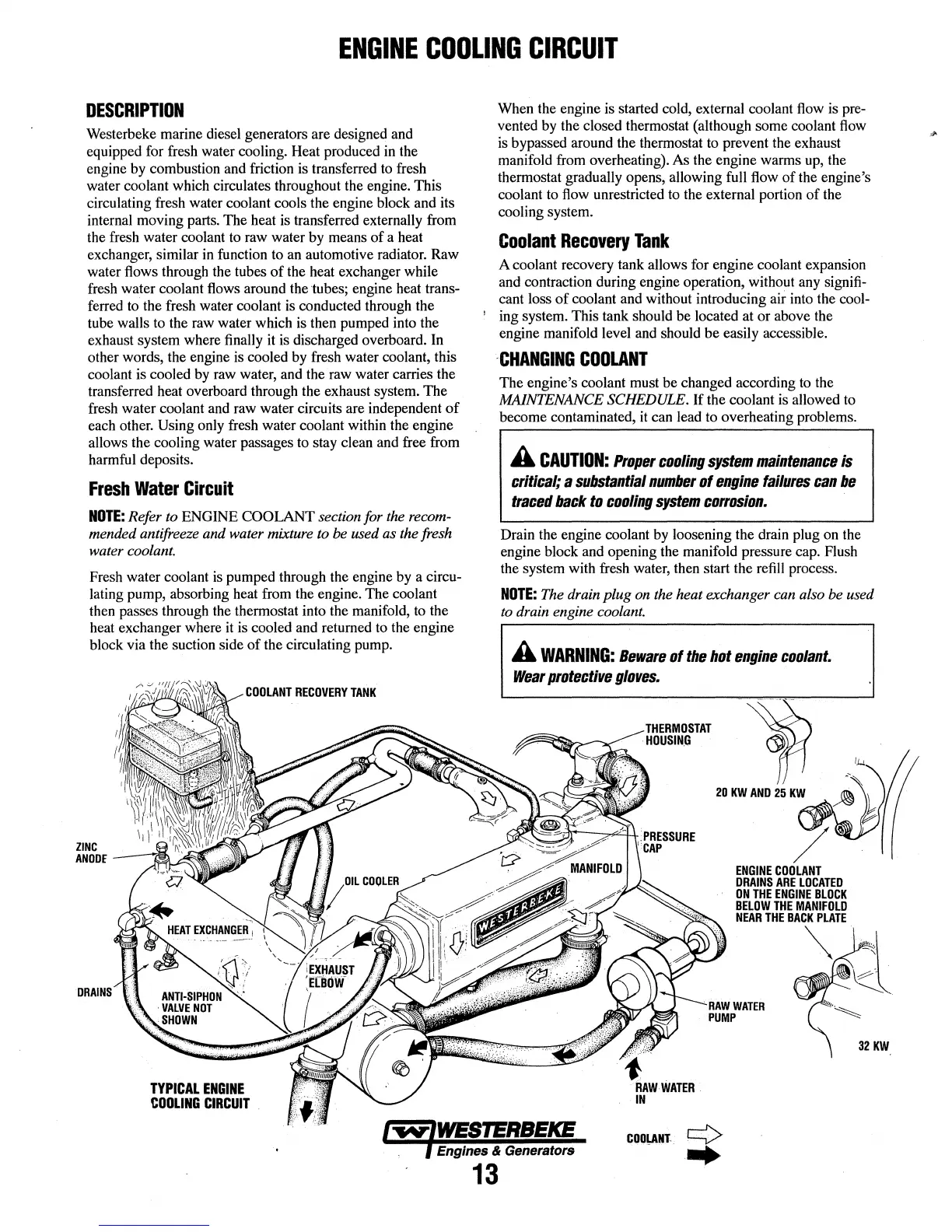

COOLANT

RECOVERY

TANK

TYPICAL

ENGINE

COOLING

CIRCUIT

When the engine is started cold, external coolant flow is pre-

vented by the closed thermostat (although some coolant flow

is

bypassed around the thermostat to prevent the exhaust

manifold from overheating). As the engine warms up, the

thermostat gradually opens, allowing full flow

of

the engine's

coolant to flow unrestricted to the external portion

of

the

cooling system.

Coolant

Recovery

Tank

A coolant recovery tank allows for engine coolant expansion

and contraction during engine operation, without any signifi-

cant loss

of

coolant and without introducing air into the cool-

' ing system. This tank should be located at

or

above the

engine manifold level and should be easily accessible.

,CHANGING

COOLANT

The engine's coolant must be changed according to the

MAINTENANCE SCHEDULE. If the coolant is allowed to

become contaminated,

it

can lead to overheating problems.

A

CAUTION:

Proper

cooling

system

maintenance

is

critical;

a

substantial

number

of

engine

failures

can

be

traced

back

to

cooling

system

corrosion.

Drain the engine coolant by loosening the drain plug on the

engine block and opening the manifold pressure cap. Flush

the system with fresh water, then start the refill process.

NOTE:

The drain

plug

on the heat exchanger can also

be

used

to drain engine coolant.

A

WARNING:

Beware

of

the

hot

engine

coolant.

Wear

protective

gloves.

THERMOSTAT

·HOUSIN.G

COOLANT

Q

Engines

&

Generators

..

13

Loading...

Loading...