FUEL

SYSTEM

BLEEDING

(PRIMING)

THE

FUEL

SYSTEM/20.0

KW

AND25.0KW

There

is

one bleed point

in

the

on-engine

fuel

system

to

open

for

the removal

of

air.

On

the

20.0

KW

and

25

KW

this bleed

screw

is

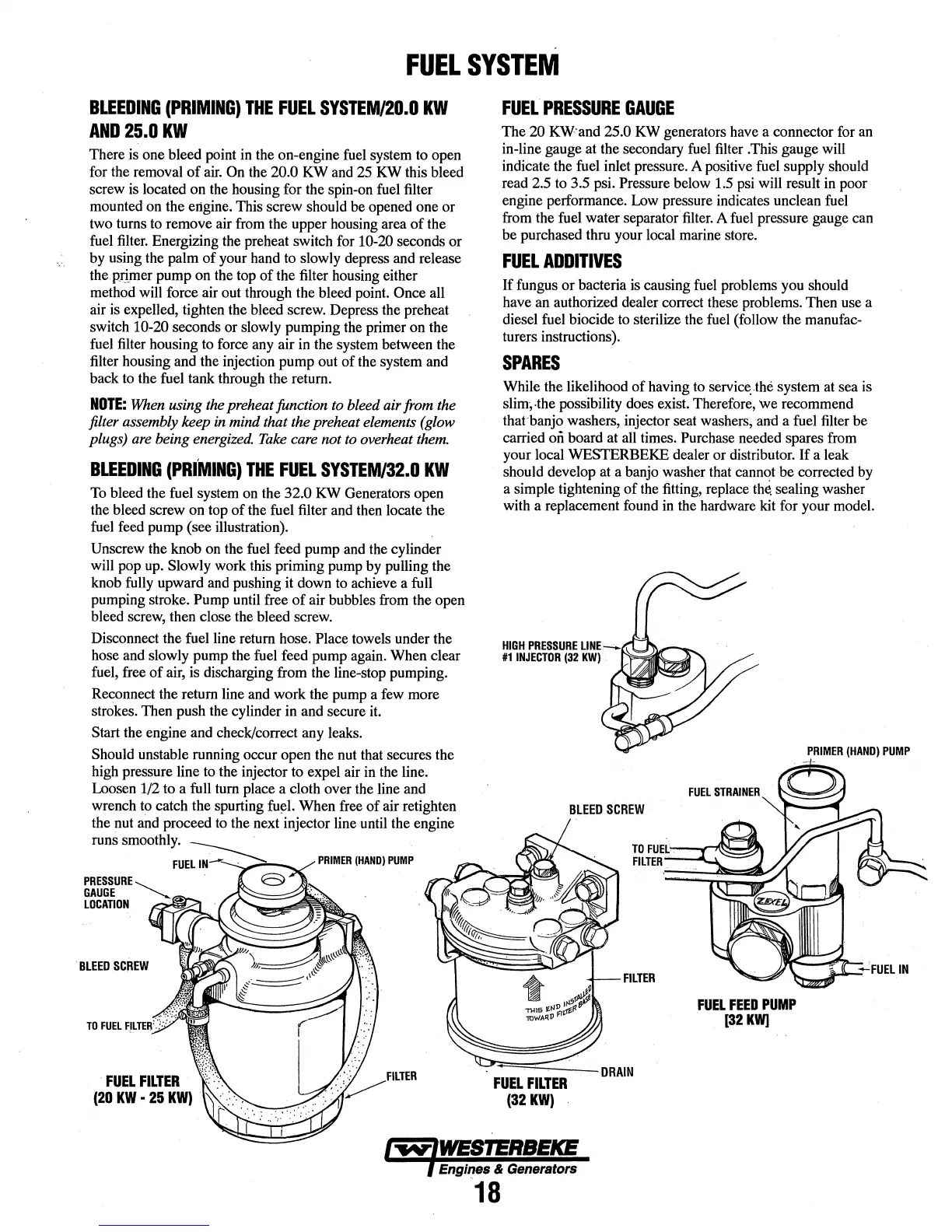

located on the housing for the spin-on fuel filter

mounted on the engine. This screw should

be

opened one or

two

turns

to

remove

air

from

the upper

housing

area

of

the

fuel

filter.

Energizing

the

preheat switch

for

10-20

seconds or

by

using the palm of your

hand

to

slowly

depress

and

release

the.pJimer pump on the

top

of the filter

housing

either

method

will

force air out through the bleed

point.

Once all

air

is

expelled, tighten the bleed screw. Depress

the

preheat

switch

10-20 seconds

or

slowly pumping

the

primer

on

the

fuel

filter

housing

to

force

any air

in

the

system

between

the

filter housing and the injection pump out of

the

system and

back

to

the

fuel

tank through the return.

NOTE:

When

using the preheat function

to

bleed air

from

the

filter assembly keep

in

mind that the preheat elements (glow

plugs)

are

being

energized.

Take

care not

to

overheat

them.

BLEEDING

(PRIMING)

THE

FUEL

SYSTEM/32.0

KW

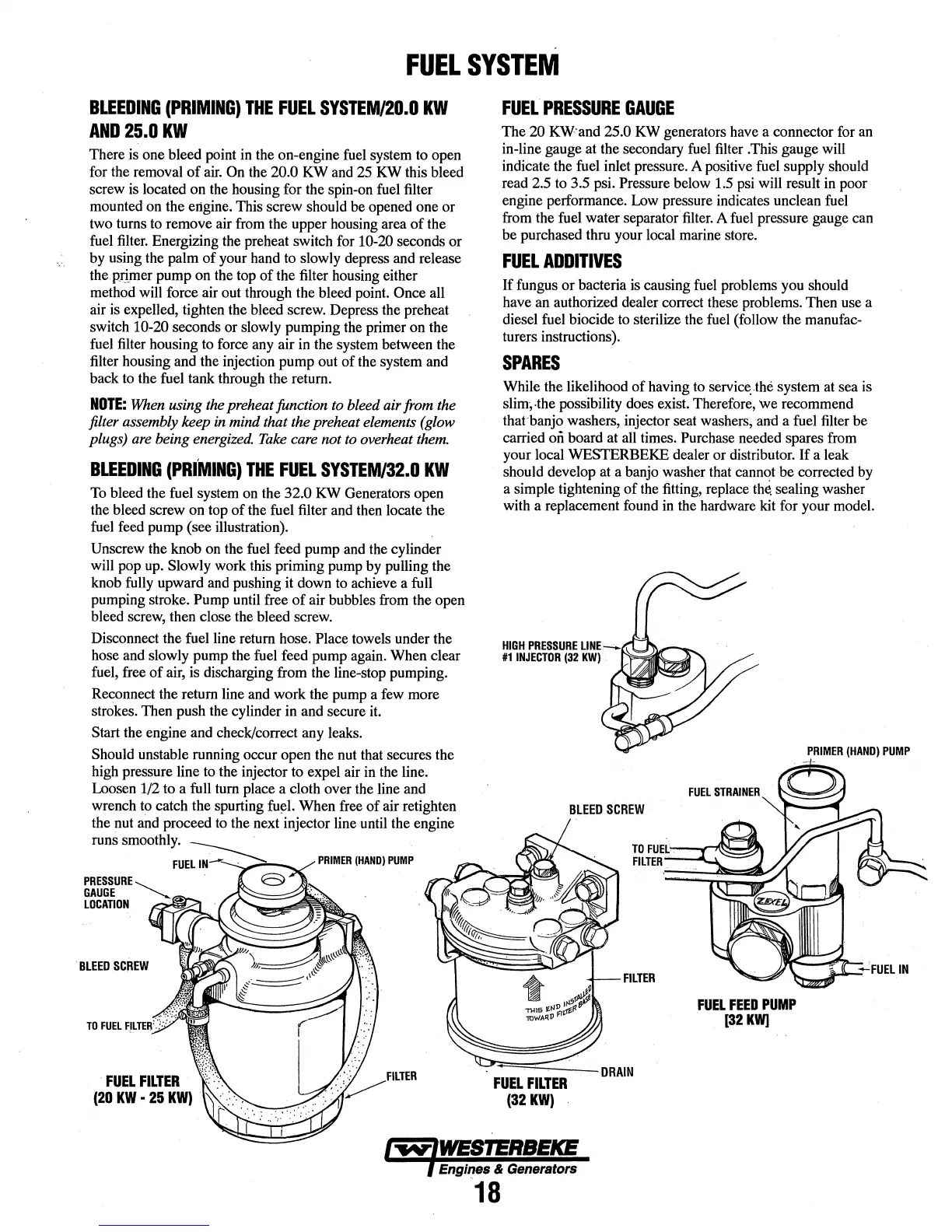

To

bleed the

fuel

system

on

the 32.0

KW

Generators open

the bleed screw on

top

of the

fuel

filter

and

then

locate the

fuel

feed

pump (see illustration).

Unscrew the knob

on

the

fuel

feed pump

and

the

cylinder

will

pop

up.

Slowly work this priming pump

by

pulling the

knob

fully

upward

and

pushing it down

to

achieve a full

pumping stroke.

Pump until

free

of air bubbles

from

the open

bleed

screw,

then close

the

bleed

screw.

Disconnect the

fuel

line return hose. Place towels under the

hose

and

slowly pump

the

fuel

feed pump

again.

When clear

fuel,

free

of

air,

is discharging from the line-stop pumping.

Reconnect the return line

and

work the pump a

few

more

strokes. Then push the cylinder in

and

secure

it.

Start the engine

and

check/correct

any

leaks.

Should unstable running occur open the

nut

that secures the

high pressure line

to

the injector

to

expel air

in

the

line.

Loosen

1!2

to

a full

turn

place a cloth over

the

line and

wrench to catch the spurting

fu~l.

When

free

of air retighten

the nut

and

proceed

to

the

next

injector line until the engine

runs smoothly.

FUEL

PRESSURE......__

GAUGE

..........._

LOCATION

.......

..,.

_....,

TO

FUEL

·

FUEL

FILTER

(20

KW

~

25

KW)

FUEL

PRESSURE

GAUGE

The

20

KW:and

25.0

KW

generators

have

a connector for

an

in-line gauge at the secondary

fuel

filter .This gauge will

indicate the fuel inlet pressure. A positive fuel supply should

read 2.5

to

3.5

psi.

Pressure below

1.5

psi

will result

in

poor

engine performance.

Low

pressure indicates unclean

fuel

from

the

fuel

water separator·

filter.

A

fuel

pressure gauge

can

be purchased thru

your

local marine store.

FUEL

ADDITIVES

If

fungus or bacteria

is

causing

fuel

problems

you

should

have

an

authorized dealer correct

these

problems. Then use a

diesel

fuel

biocide

to

sterilize the

fuel

(follow the manufac-

turers instructions).

SPARES

While the likelihood of having

to

servi~

.the

system

at

sea

is

slim;.the possibility

does

exist. Therefore, we recommend

that banjo washers, injector seat washers;

and a

fuel

filter

be

carried

on

board

at

all

times.

Purchase needed spares

from

your local WESTERBEKE dealer or distributor. If a leak

should develop

at

a banjo washer

that

cannot be corrected

by

a simple tightening of

the

fitting,

replace tM sealing washer

with a replacement

found

in

the

hardware

kit

for your

model.

HIGH

PRESSURE

LINE.-:..

1#11NJECTOR

(32

KW)

•

BLEED

SCREW

FILTER

FUEL

FEED

PUMP

(32

KW]

PRIMER

(HAND)

PUMP

j...,.,.IWESTERBEKE

l Engines & Generators

18

Loading...

Loading...