TIMING

BELT

DISASSEMBLY

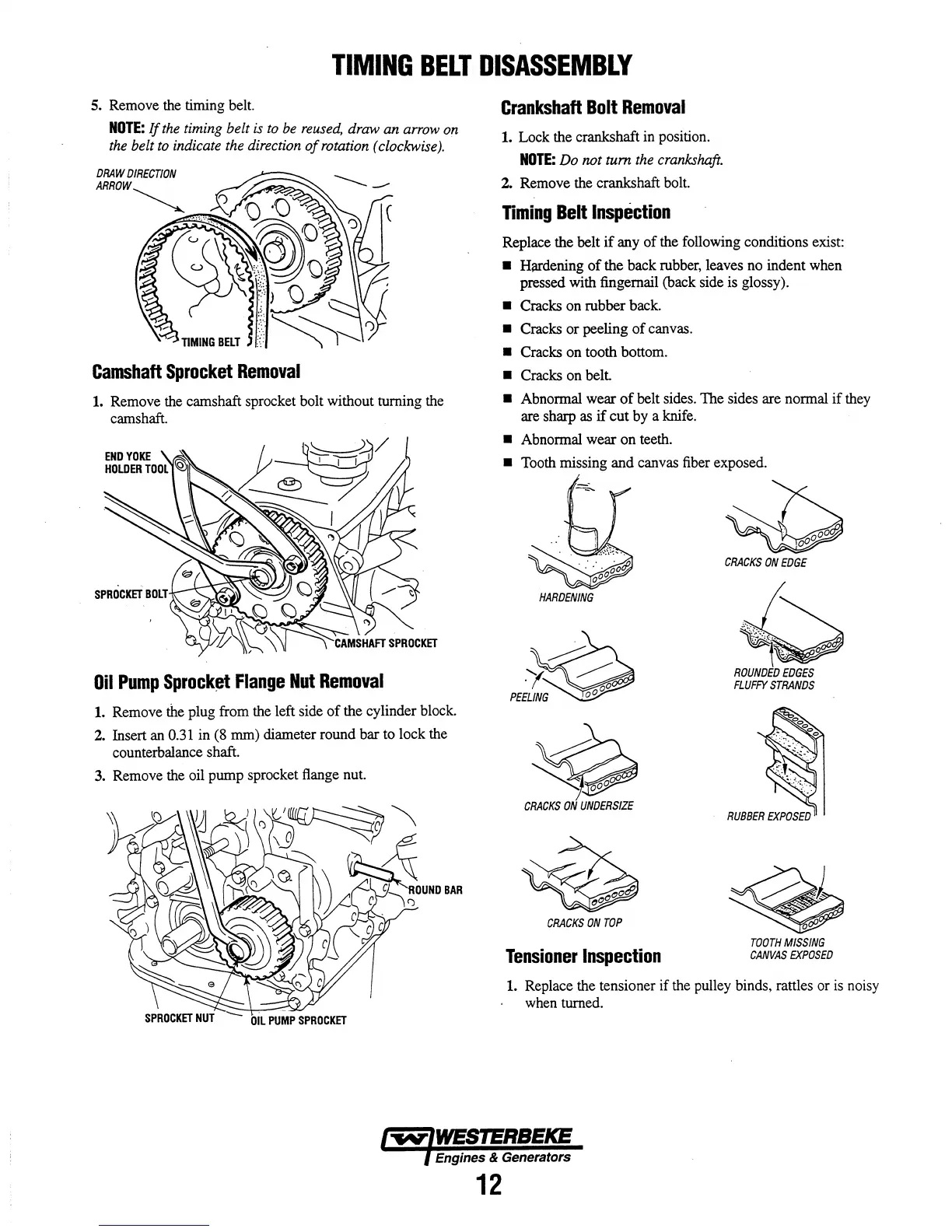

5. Remove the timing belt.

NOTE:

lfthe

timing belt

is

to be reused, draw

an

arrow on

the belt to indicate the direction

of

rotation (clockwise)

..

Camshaft

Sprocket

Removal

1.

Remove the camshaft sprocket bolt without turning the

camshaft.

SPROCKET

BOLT

Oil

Pump

Sprock~

Flange

Nut

Removal

1. Remove the plug from the left side

of

the cylinder block.

2. Insert an

0.31 in (8 mm) diameter round bar to lock the

counterbalance shaft.

3. Remove the oil pump sprocket flange nut.

OIL

PUMP

SPROCKET

Crankshaft

Bolt

Removal

1. Lock the crankshaft in position.

NOTE:

Do

not

tum

the crankshaft.

2.

Remove the crankshaft bolt.

Timing

Belt

Inspection

Replace the belt

if

any

of

the following conditions exist:

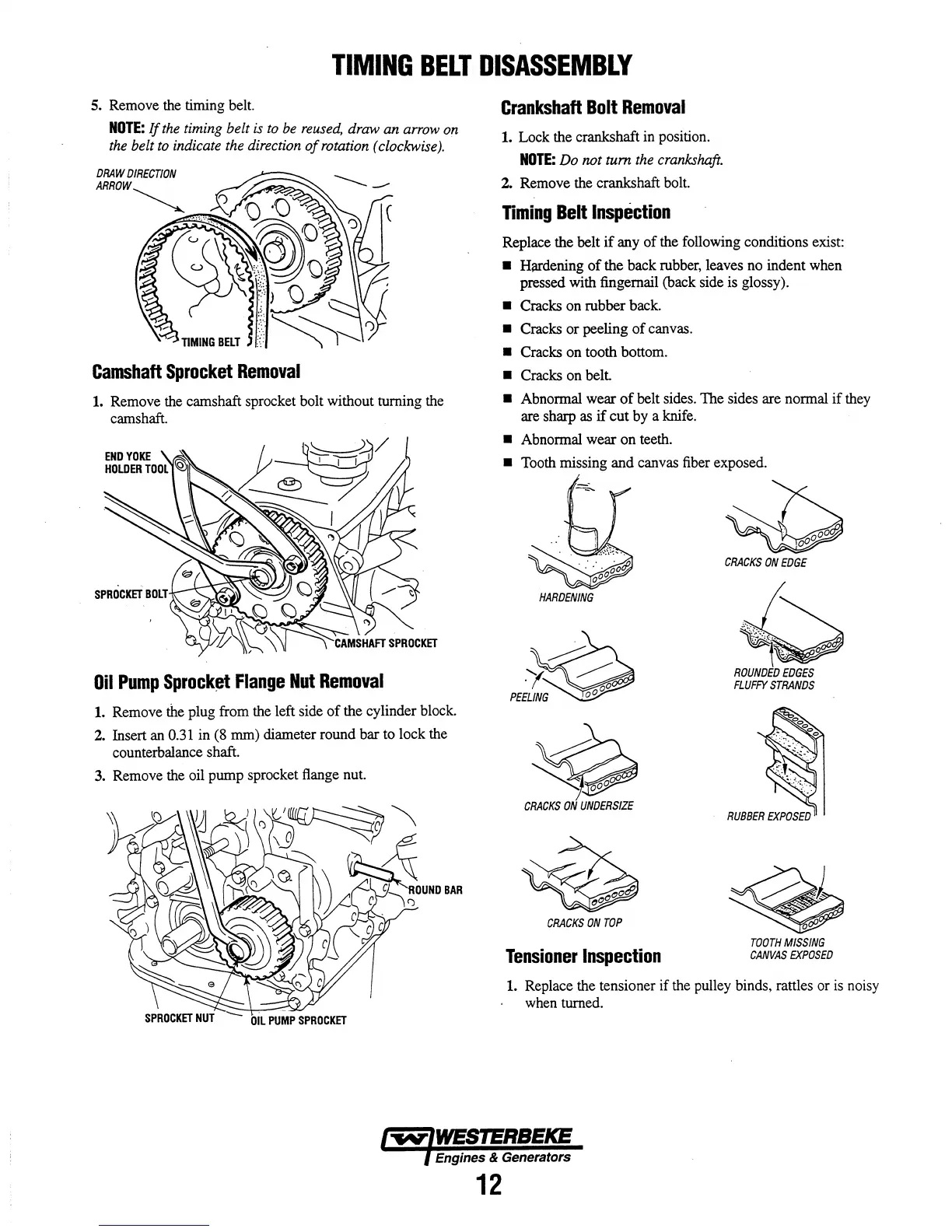

• Hardening

of

the back rubber, leaves no indent when

pressed with fingernail (back side is glossy).

• Cracks on rubber back.

• Cracks

or

peeling

of

canvas.

• Cracks on tooth bottom.

• Cracks on

belt

• Abnormal wear

of

belt sides. The sides are normal

if

they

are

sharp as

if

cut

by

a knife.

• Abnormal wear on teeth.

• Tooth missing and canvas fiber exposed.

HARDENING

~

CRACKS

ON

UNDERSIZE

CRACKS

ON

TOP

Tensioner

Inspection

CRACKS

ON

EDGE

ROUNDED

EDGES

FLUFFY

STRANDS

TOOTH

MISSING

CANVAS

EXPOSED

1.

Replace the tensioner if the pulley binds, rattles or

is

noisy

when turned.

Engines & Generators

12

Loading...

Loading...