FRONT

CASE

I

COUNTERBALANCE

SHAFT

AND

OIL

PUMP

INSTALLATION

Counterbalance

Rear

Bearing

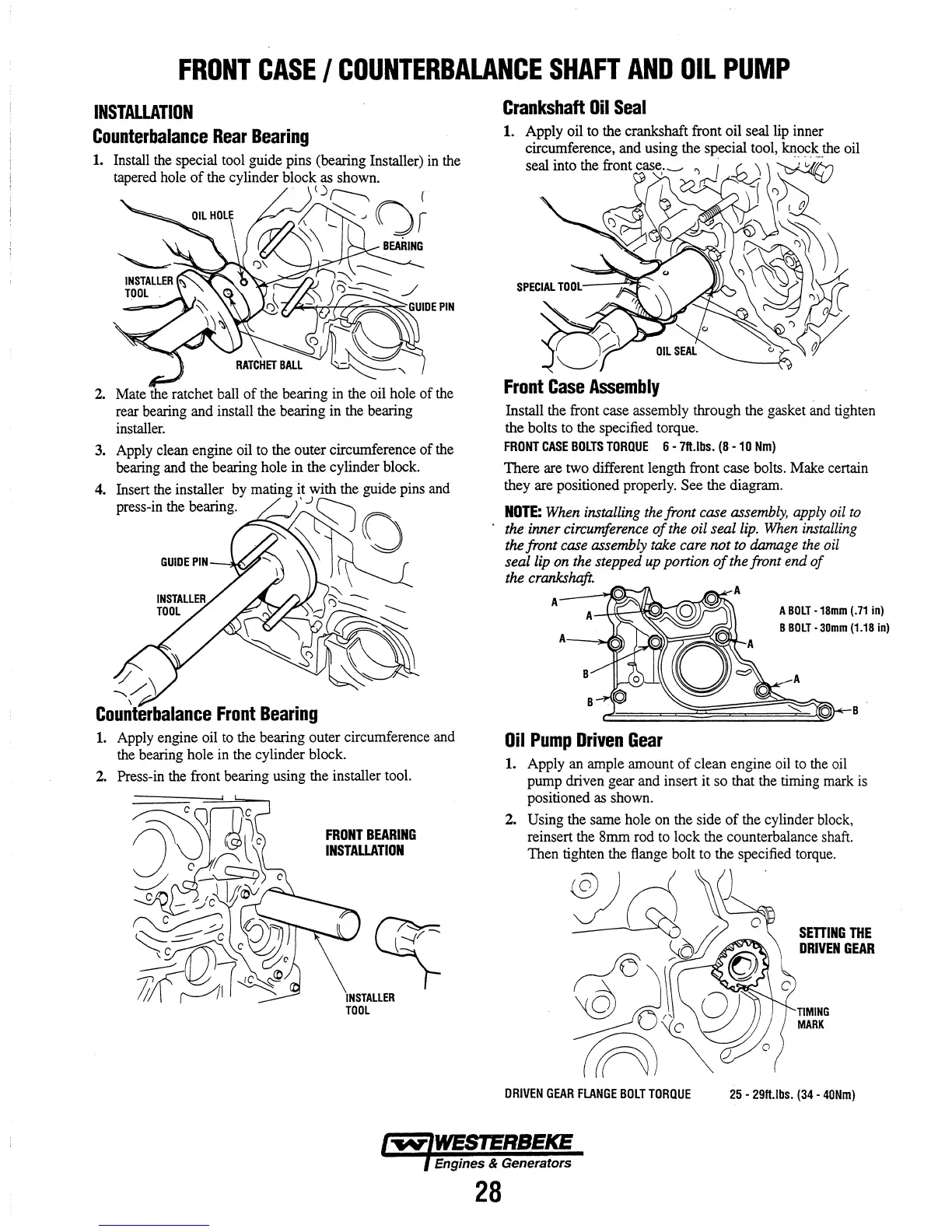

1. Install the special tool guide pins (bearing Installer) in the

tapered hole

of

the cylinder block as shown .

. \

t)r---,

(

OIL

HOLE

~

~

J

0..

r

\

'-

"::J

~\

BEARING

2. Mate the ratchet ball

of

the bearing in the oil hole

of

the

rear bearing and install the bearing in the bearing

installer.

3. Apply clean engine oil to the outer circumference

of

the

bearing and the bearing hole in the cylinder block.

4.

GUIDE

PIN

-

__

.v

\

Counterbalance

Front

Bearing

1. Apply engine oil to the bearing outer circumference and

the bearing hole in the cylinder block.

2. Press-in the front bearing using the installer tool.

FRONT

BEARING

INSTALLATION

Crankshaft

Oil

Seal

1.

Front

Case

Assembly

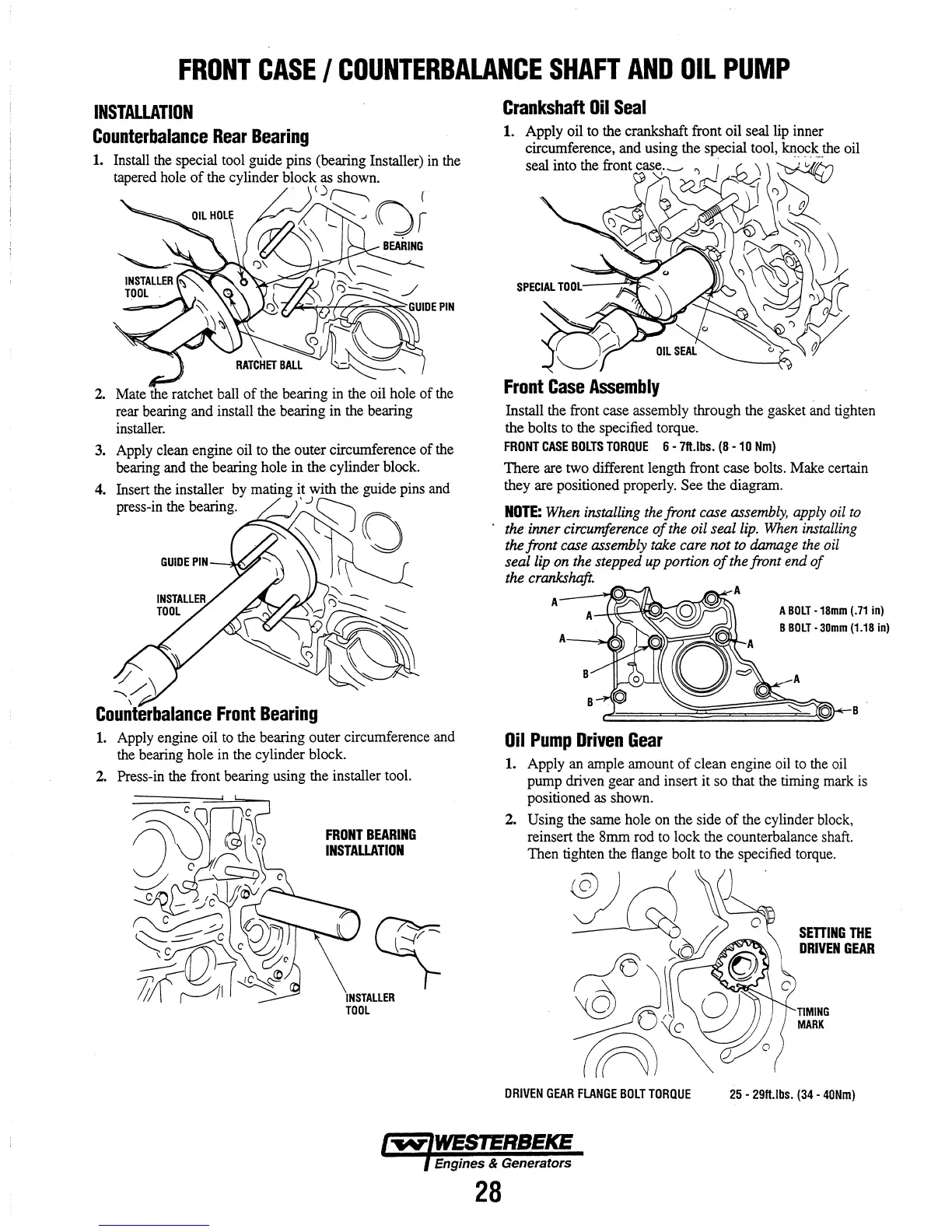

Install the front case assembly through the gasket and tighten

the bolts to the specified torque.

FRONT

CASE

BOLTS

TORQUE

6 -

7ft.Jbs.

(8

-10

Nm)

There are two different length front case bolts. Make certain

they are positioned properly. See the diagram.

NOTE:

When

installing

the

front case

assembly,

apply

oil

to

the inner circumference

of

the

oil seal

lip.

When

installing

the front

case

assembly take

care

not

to

damage

the

oil

seal

lip

on

the stepped

up

portion

of

the front end

of

the crankshaft.

A

A_-.r.-

B

B

Oil

Pump

Driven

Gear

A

BOLT

•

18mm

(.71

in)

B

BOLT·

30mm

(1.18

in)

B

1.

Apply an ample amount

of

clean engine oil to the oil

pump driven gear and insert it so that the timing mark is

positioned as shown.

2.

Using the same hole on the side

of

the cylinder block,

reinsert the 8mm rod to lock the counterbalance shaft.

Then tighten the flange bolt to the specified torque.

DRIVEN

GEAR

FLANGE

BOLT

TORQUE

SETTING

THE

DRIVEN

GEAR

TIMING

MARK

25

-

29ft.lbs.

(34·

40Nm)

Engines & Generators

28

Loading...

Loading...