CYLINDER

BLOCK

INSPECTION

AND

PISTON

CLEARANCE

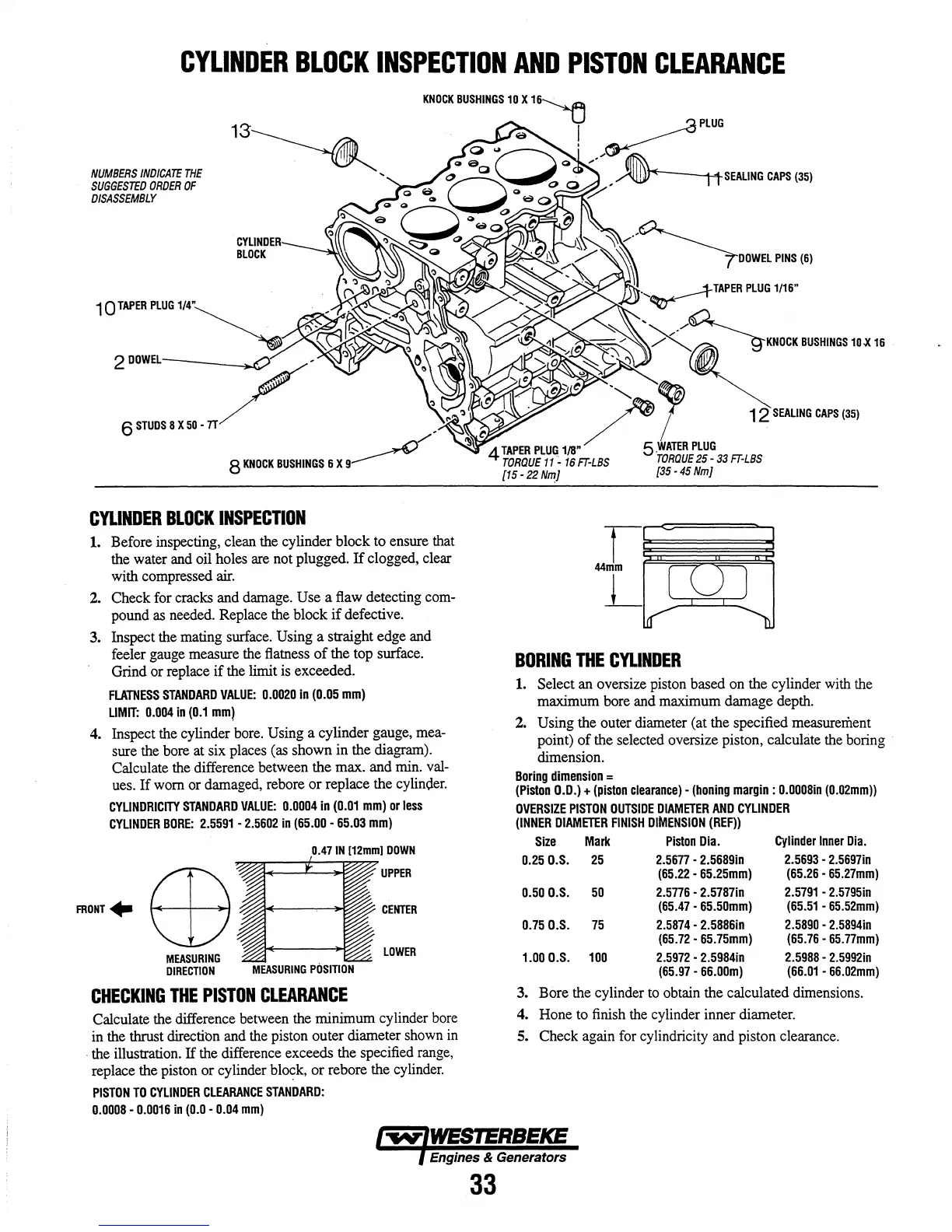

NUMBERS

INDICATE

THE

SUGGESTED

ORDER

OF

DISASSEMBLY

2DDWEL--_

6

STIJIlS

"01·

n/

.

8

KNOCK

BUSHINGS

6 X

9~

CRINDER

BLOCK

INSPECTION

1. Before inspecting, clean the cylinder block to ensure that

the water and oil holes are not plugged.

If

clogged, clear

with compressed air.

2. Check for cracks and damage.

Use

a flaw detecting com-

pound as needed. Replace the block

if

defective.

3. Inspect the mating surface.

Using a straight edge and

feeler gauge measure the flatness

of

the top surface.

Grind or replace

if

the limit is exceeded.

FLATNESS

STANDARD

VALUE:

0.0020

in

(0.05

mm)

LIMIT:

0.004

in

(0.1

mm)

4. Inspect the cylinder bore. Using a cylinder gauge, mea-

sure the bore at six places (as shown in the diagram).

Calculate the difference between the max. and min.

val-

ues.

If

worn or damaged, rebore

or

replace the cylinder.

CYLINDRICITY

STANDARD

VALUE:

0.0004

in

(0.01

mm)

or

less

CYLINDER

BORE:

2.5591

-

2.5602

in

(65.00

-

65.03

mm)

UPPER

~f+------l~~

CENTER

MEASURING

DIRECTION

MEASURING

POSITION

LOWER

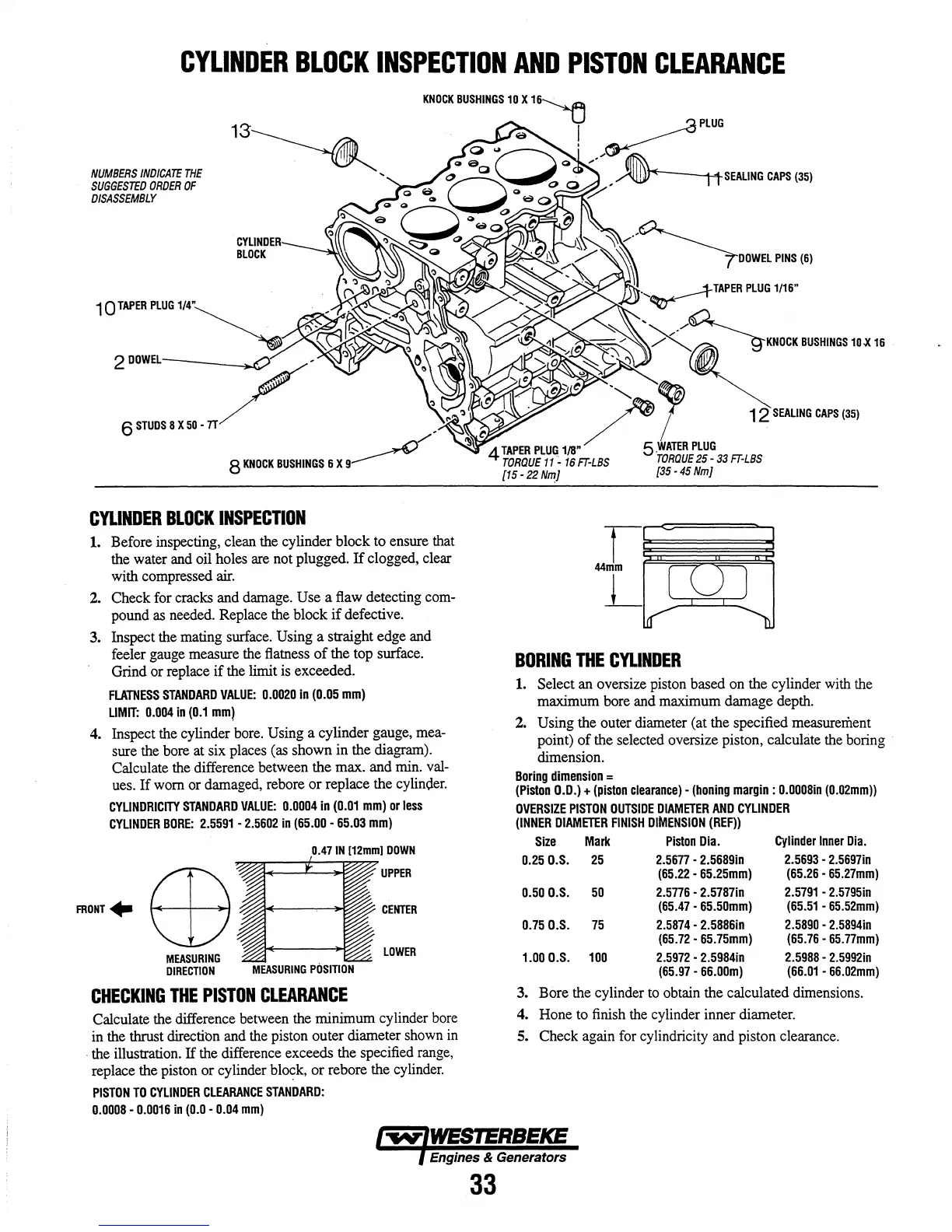

CHECKING

THE

PISTON

CLEARANCE

Calculate the difference between the minimum cylinder bore

in the thrust direction and the piston outer diameter shown in

. the illustration.

If

the difference exceeds the specified range,

replace the piston or cylinder

blo,?k,

or

rebore the cylinder.

PISTON

TO

CYLINDER

CLEARANCE

STANDARD:

0.0008

-

0.0016

in

(0.0

-

0.04

mm)

1"1

SEALING

CAPS

(35)

BORING

THE

CRINDER

1. Select an oversize piston based on the cylinder with the

maximum bore and maximum damage depth.

2.

Using the outer diameter (at the specified measurement

point)

of

the selected oversize piston, calculate the boring

dimension.

Boring

dimension

=

(Piston

0.0.) +

(piston

clearance)

-

(honing

margin:

0.0008in

(0.02mm))

OVERSIZE

PISTON

OUTSIDE

DIAMETER

AND

CYLINDER

(INNER

DIAMETER

FINISH

DIMENSION

(REF))

Size

Mark

Piston

Dia.

Cylinder

Inner

Dia.

0.250.S.

25

2.5677

-

2.5689in

2.5693

-

2.5697in

(65.22

-

65.25mm)

(65.26

-

65.27mm)

0.500.S.

50

2.5776

-

2.5787in

2.5791

-

2.5795in

(65.47

-

65.50mm)

(65.51

-

65.52mm)

0.750.S.

75

2.5874

-

2.58861n

2.5890

-

2.5894in

(65.72

-

65.75mm)

(65.76

-

65.77mm)

1.000.S.

100

2.5972

-

2.5984in

2.5988

-

2.59921n

(65.97

-

66.00m)

(66.01

-

66.02mm)

3. Bore the cylinder to obtain the calculated dimensions.

4. Hone to finish the cylinder inner diameter.

S. Check again for cylindricity and piston clearance .

Engines & Generators

33

Loading...

Loading...