ENGINE/GENERATOR

TROUBLESHOOTING

OPERATING

PROCEDURES

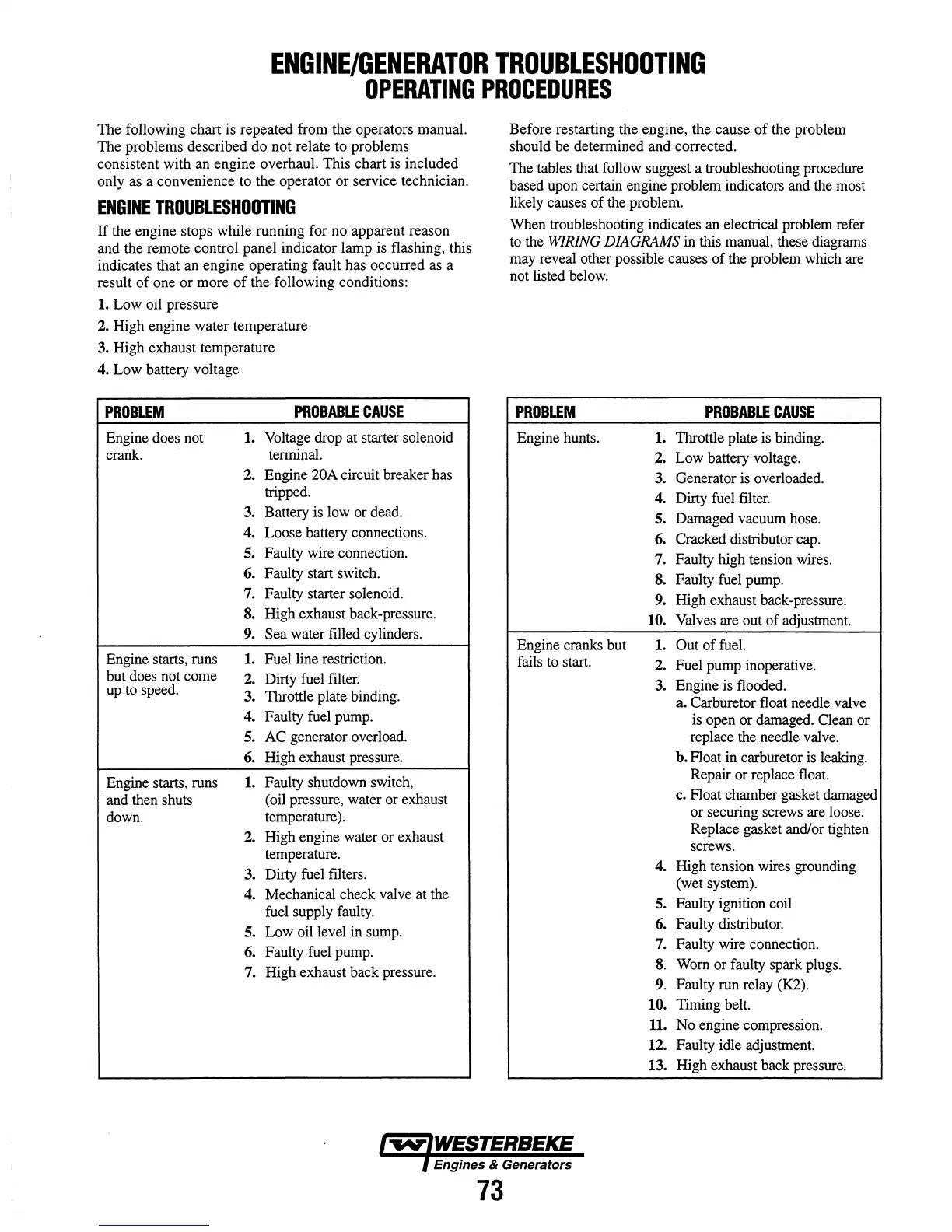

The following chart is repeated from the operators manual.

The problems described do not relate to problems

consistent with an engine overhaul. This chart is included

only as a convenience to the operator

or

service technician.

ENGINE

TROUBLESHOOTING

If

the engine stops while running for no apparent reason

and the remote control panel indicator lamp is flashing, this

indicates that an engine operating fault has occurred as a

result

of

one

or

more

of

the following conditions:

1. Low oil pressure

2. High engine water temperature

3. High exhaust temperature

4. Low battery voltage

PROBLEM

PROBABLE

CAUSE

Engine does not

1.

Voltage drop at starter solenoid

crank.

terminal.

2. Engine 20A circuit breaker has

tripped.

3.

Battery is low or dead.

4.

Loose battery connections.

s.

Faulty wire connection.

6.

Faulty start switch.

7.

Faulty starter solenoid.

S.

High exhaust back-pressure.

9.

Sea water filled cylinders.

Engine starts, runs

1.

Fuel line restriction.

but does not come

2.

Dirty fuel filter.

up to speed.

3.

Throttle plate binding.

4.

Faulty fuel pump.

S.

AC generator overload.

6.

High exhaust pressure.

Engine starts, runs

1.

Faulty shutdown switch,

. and then shuts (oil pressure, water or exhaust

down.

temperature).

2.

High engine water or exhaust

temperature.

3.

Dirty fuel filters.

4.

Mechanical check valve at the

fuel supply faulty.

S.

Low oil level in sump.

6.

Faulty fuel pump.

7.

High exhaust back pressure.

Before restarting the engine, the cause

of

the problem

should be determined and corrected.

The tables that follow suggest a troubleshooting procedure

based upon certain engine problem indicators and the most

likely causes

of

the problem.

When troubleshooting indicates an electrical problem refer

to the WIRING DIAGRAMS in this manual, these diagrams

may reveal other possible causes

of

the problem which are

not listed below.

PROBLEM

PROBABLE

CAUSE

Engine hunts.

1.

Throttle plate is binding.

2.

Low battery voltage.

3. Generator is overloaded.

4.

Dirty fuel filter.

s.

Damaged vacuum hose.

6.

Cracked distributor cap.

7.

Faulty high tension wires.

S. Faulty fuel pump.

9. High exhaust back-pressure.

10.

Valves are out

of

adjustment.

Engine cranks but

1.

Out

of

fuel.

fails to start.

2.

Fuel pump inoperative.

3.

Engine is flooded.

a. Carburetor float needle valve

is open or damaged. Clean or

replace the needle valve.

b.

Float in carburetor is leaking.

Repair

or

replace float.

c. Float chamber gasket damaged

or

securing screws are loose.

Replace gasket and/or tighten

screws.

4. High tension wires grounding

(wet system).

s.

Faulty ignition coil

6.

Faulty distributor.

7.

Faulty wire connection.

S.

Worn or faulty spark plugs.

9.

Faulty run relay (K2).

10.

Timing belt.

11.

No

engine compression.

12.

Faulty idle adjustment.

13. High exhaust back pressure.

Engines & Generators

73

Loading...

Loading...