ENGINE

ADJUSTMENTS

NOTE:

WESTERBEKE recommends that the following

engine adjustments be performed by a competent engine

,mechanic. The information below is provided to assist the

mechanic.

ENGINE

SPEED

(HERTZ)

ADJUSTMENT

Governor

The belt-driven, mechanically operated governor maintains

the engine's rpm under various load conditions. Engine speed

determines the hertz and voltage output of the generator.

Governor

Adiusbnents

Operate the generator to bring the unit

up

to operating tem-

perature before adjusting the governor.

NOTE:

If

the

governor is severely out

of

adjustment, manually

adjust the linkage at no-load

to

obtain a safe output voltage

before proceeding with the adjustment.

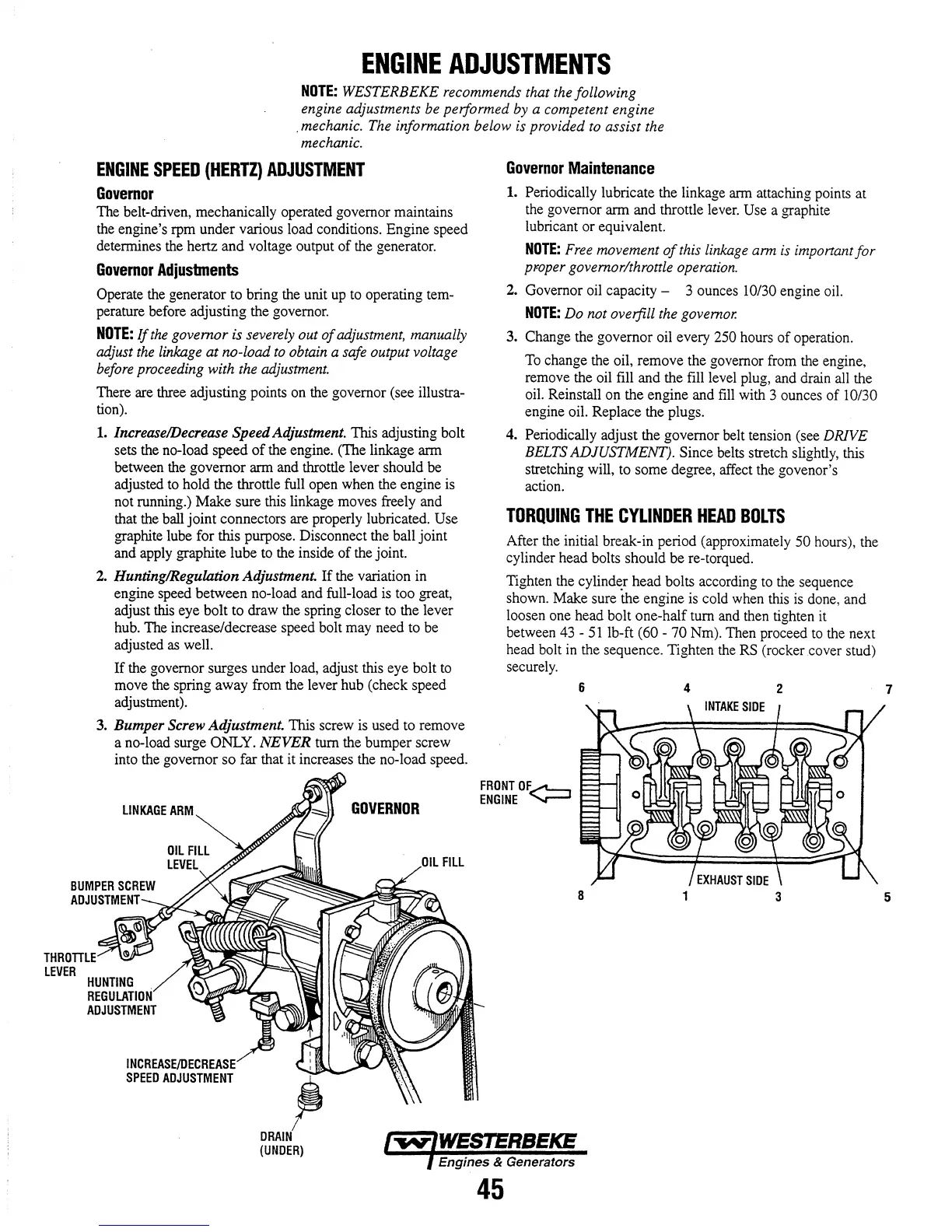

There are three adjusting points on the governor (see illustra-

tion).

1.

Increase/Decrease Speed Adjustment. This adjusting bolt

sets the no-load speed

of

the engine. (The linkage arm

between the governor arm and throttle lever should be

adjusted to hold the throttle full open when the engine

is

not running.) Make sure this linkage moves freely and

that the ball joint connectors are properly lubricated. Use

graphite lube for this purpose. Disconnect the ball joint

and apply graphite lube to the inside

of

the joint.

2.

Hunting/Regulation Adjustment.

If

the variation in

engine speed between no-load and full-load

is

too great,

adjust this eye bolt to draw the spring closer

to

the lever

hub. The increase/decrease speed bolt may need to be

adjusted

as

well.

If the governor surges under load, adjust this eye bolt

to

move the spring away from the lever hub (check speed

adjustment).

3.

Bumper Screw Adjustment. This screw

is

used to remove

a no-load surge

ONLY.

NEVER

turn the bumper screw

into the governor so far that it increases the no-load speed.

LINKAGE

ARM

INCREASEf[IECFIEA~;E

SPEED

ADJUSTMENT

GOVERNOR

L

FILL

Governor

Maintenance

1.

Periodically lubricate the linkage arm attaching points at

the governor arm and throttle lever.

Use a graphite

lubricant or equivalent.

NOTE:

Free movement

of

this linkage arm

is

important

for

proper governor/throttle operation.

2. Governor oil capacity - 3 ounces 10/30 engine oil.

NOTE:

Do not overfill the governor.

3. Change the governor oil every 250 hours

of

operation.

To

change the oil, remove the governor from the engine,

remove the oil fill and the fill level plug, and drain all the

oil. Reinstall on the engine and

fill

with 3 ounces

of

I 0/30

engine oil. Replace the plugs.

4. Periodically adjust the governor belt tension (see

DRIVE

BELTS ADJUSTMENT). Since belts stretch slightly, this

stretching will, to some degree, affect the govenor's

action.

TORQUING

THE

CYLINDER

HEAD

BOLTS

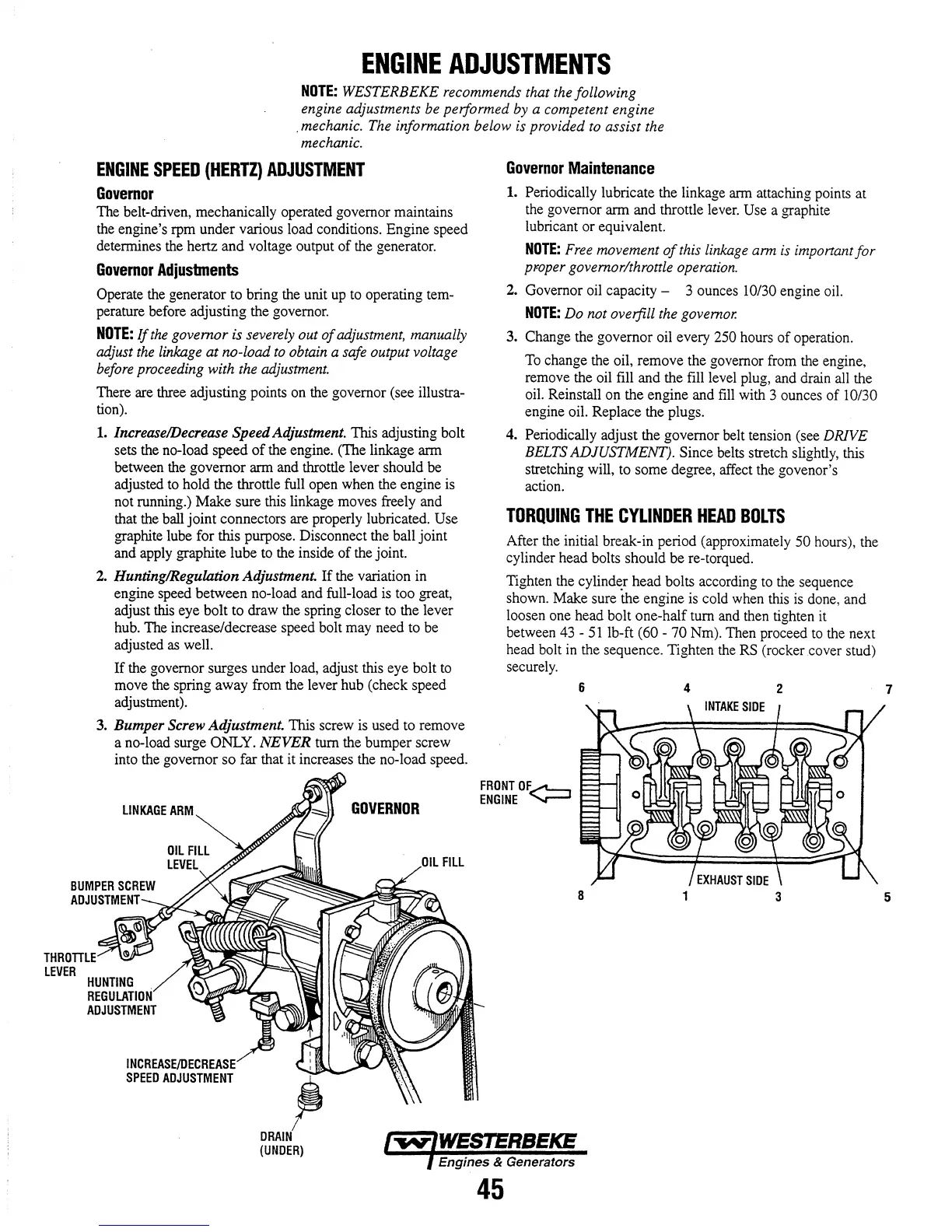

After the initial break-in period (approximately 50 hours), the

cylinder head bolts should be re-torqued.

Tighten the cylinder head bolts according to the sequence

shown. Make sure

the engine

is

cold when this

is

done, and

loosen one head bolt one-half turn and then tighten it

between

43

-

51

lb-ft (60 - 70 Nm). Then proceed

to

the next

head bolt

in

the sequence. Tighten the

RS

(rocker cover stud)

securely.

FRONTOF~

ENGINE

'-r-'

6

4

2

(UNDER)

Engines & Generators

45

7

Loading...

Loading...