ENGINE

ADJUSTMENTS

NOTE:

WESTERBEKE

recommends

that

the

following

engine

adjustments

be

performed

by

a competent

engine

mechanic.

The

information below

is

provided

to

assist

the

mechanic.

VALVE

CLEARANCE

ADJUSTMENT

NOTE:

Retorque

the

cylinder head bolts before adjusting

the

engine's

valves

(see

TORQUING

THE CYUNDER

HEAD

BOLTS).

1.

Remove the rocker cover and gasket.

2. Rotate the crankshaft in the normal direction

of

rotation,

placing the No. 1 piston at the top

of

its compression

stroke with the exhaust and intake valves completely

closed. Adjust the intake and exhaust valves for No. 1

cylinder, the exhaust valve for

No.2

cylinder, and the

intake valve for

No.3

cylinder (see chart).

3. Rotate the crankshaft

180° in its normal direction

of

rotation. Locate the piston in No. 1 cylinder at the top

of

its exhaust stroke. Adjust the intake valve for

No.2

cylinder and the exhaust valve for

No.3

cylinder (see

chart).

CYLINDER

#

CRANK

ANGLE

1 2 3

When

No.

1

piston

is

set

at

top

of

IN

•

•

compression

stroke

•

•

EX

When

No.

1

piston

is

positioned

IN

•

at

top

of

exhaust

stroke

EX

•

4

••

Replace the rocker cover along with a new rocker cover

gasket..

Rocker

cover

torque:

2.9-5.1

Ib-n

(4

- 7

Nm)

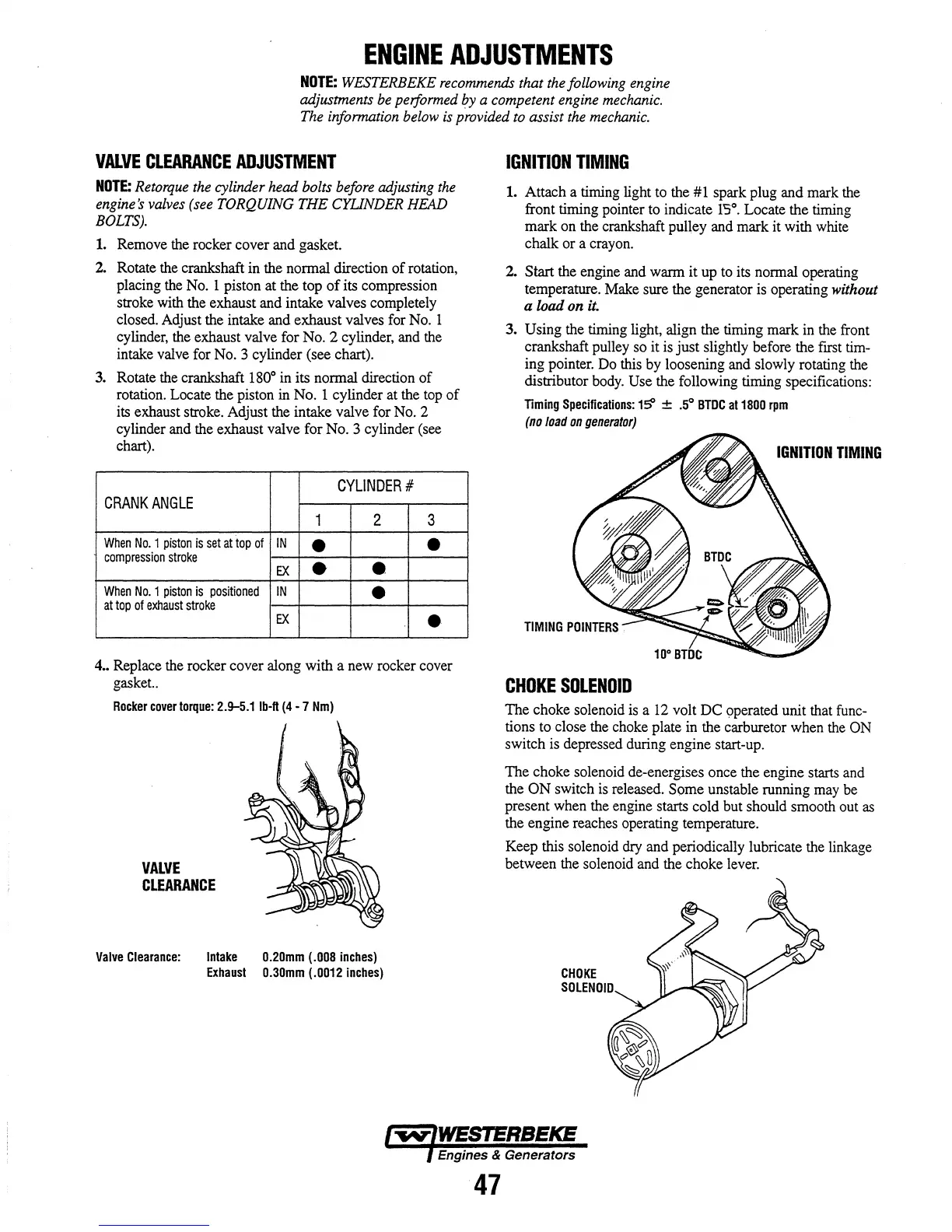

VALVE

CLEARANCE

Valve

Clearance:

Intake

0.20mm

(.008

inches)

Exhaust

0.30mm

(.0012

inches)

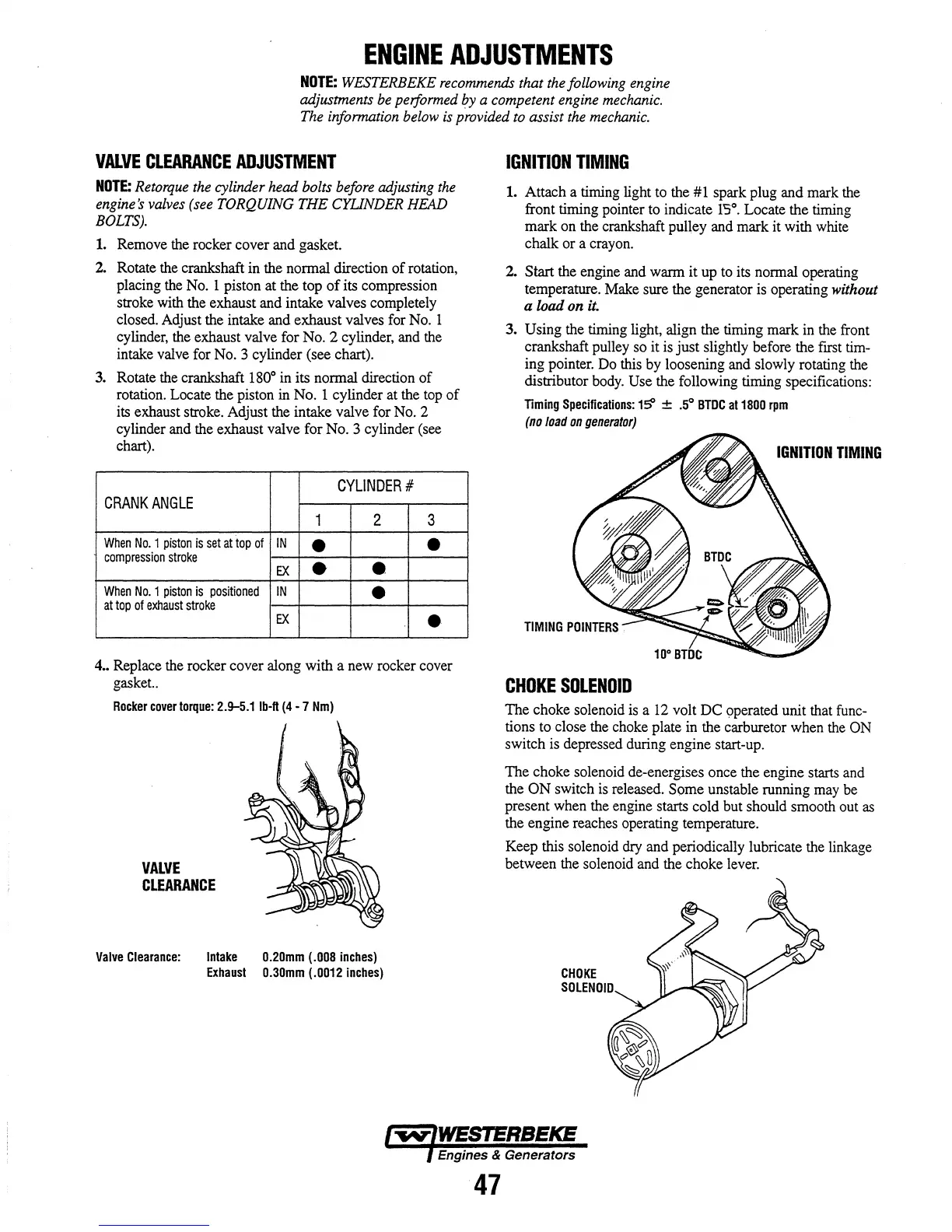

IGNITION

TIMING

1.

Attach a timing light to the #1 spark plug and mark the

front timing pointer to indicate

1'5°.

Locate the timing

mark on the crankshaft pulley and mark it with white

chalk or a crayon.

2.

Start

the engine and warm it up to its normal operating

temperature. Make sure the generator is operating without

a load

on

it.

3. Using the timing light, align the timing mark in the front

crankshaft pulley so it is

just

slightly before the

fITSt

tim-

ing pointer. Do this by loosening and slowly rotating the

distributor body.

Use the following timing specifications:

Timing

Specifications:

15' ±

.5°

BTDC

at

1800

rpm

(no

load

on

generator)

IGNITION

TIMING

CHOKE

SOLENOID

The choke solenoid is a

12

volt

DC

9perated unit that func-

tions to close the choke plate in the carburetor when the

ON

switch is depressed during engine start-up.

The choke solenoid de-energises once the engine starts and

the

ON

switch

is

released. Some unstable running may be

present when the engine starts cold but should smooth out

as

the engine reaches operating temperature.

Keep this solenoid

dry and periodically lubricate the linkage

between the solenoid and the choke lever.

CHOKE

SOLENOID

Engines & Generators

47

Loading...

Loading...