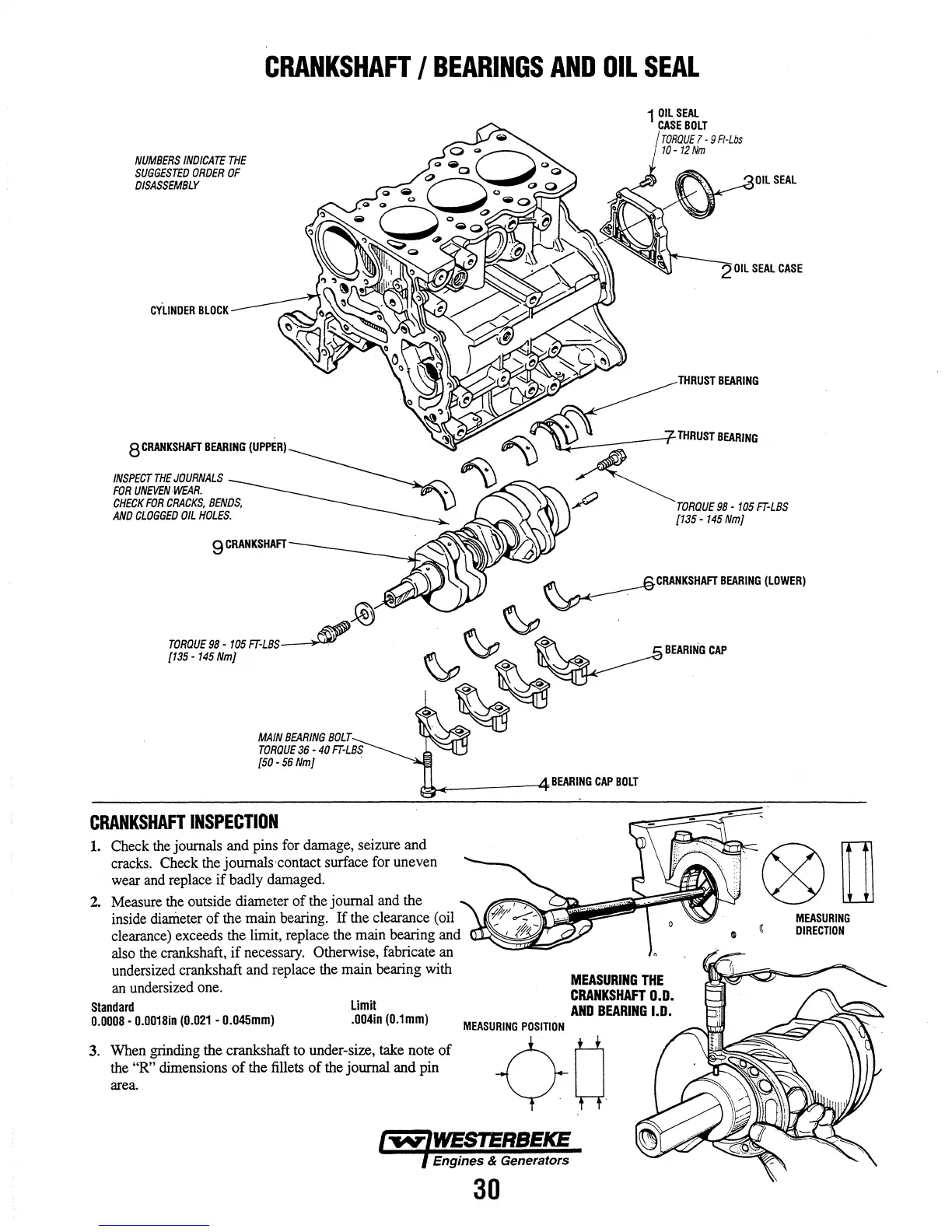

CRANKSHAFT

I

BEARINGS

AND

OIL

SEAL

NUMBERS

INDICATE

THE

SUGGESTED

ORDER

OF

DISASSEMBLY

CYLINDER

BLOCK

8

CRANKSHAFT

BEARING:

(UPPER)

INSPECT

THE

JOURNALS

FOR

UNEVEN·WEAR.

CHECK

FOR

CRACKS,

BENDS,

AND

CLOGGED

OIL

HOLES.

9

CRANKSHAFT

TORQUE

98 -

105

FT-LBS

_--"A?~.

~

[135 - 145

Nm]

MAIN

BEARING

BOLT

TORQUE

36 -

40

FT-LBS

[50-56

Nm]

1

OIL

SEAL

CASE

BOLT

I

TORQUE

1 -9

Ft-Lbs

/10-12Nm

\\

~~

__

---.

THRUST

BEARING

~

~

TORQUE

98 -

105

FT-LBS

[135 - 145

Nm]

~-+-

_____

"f'BEARING

CAP

BOLT

CRANKSHAFT

INSPECTION

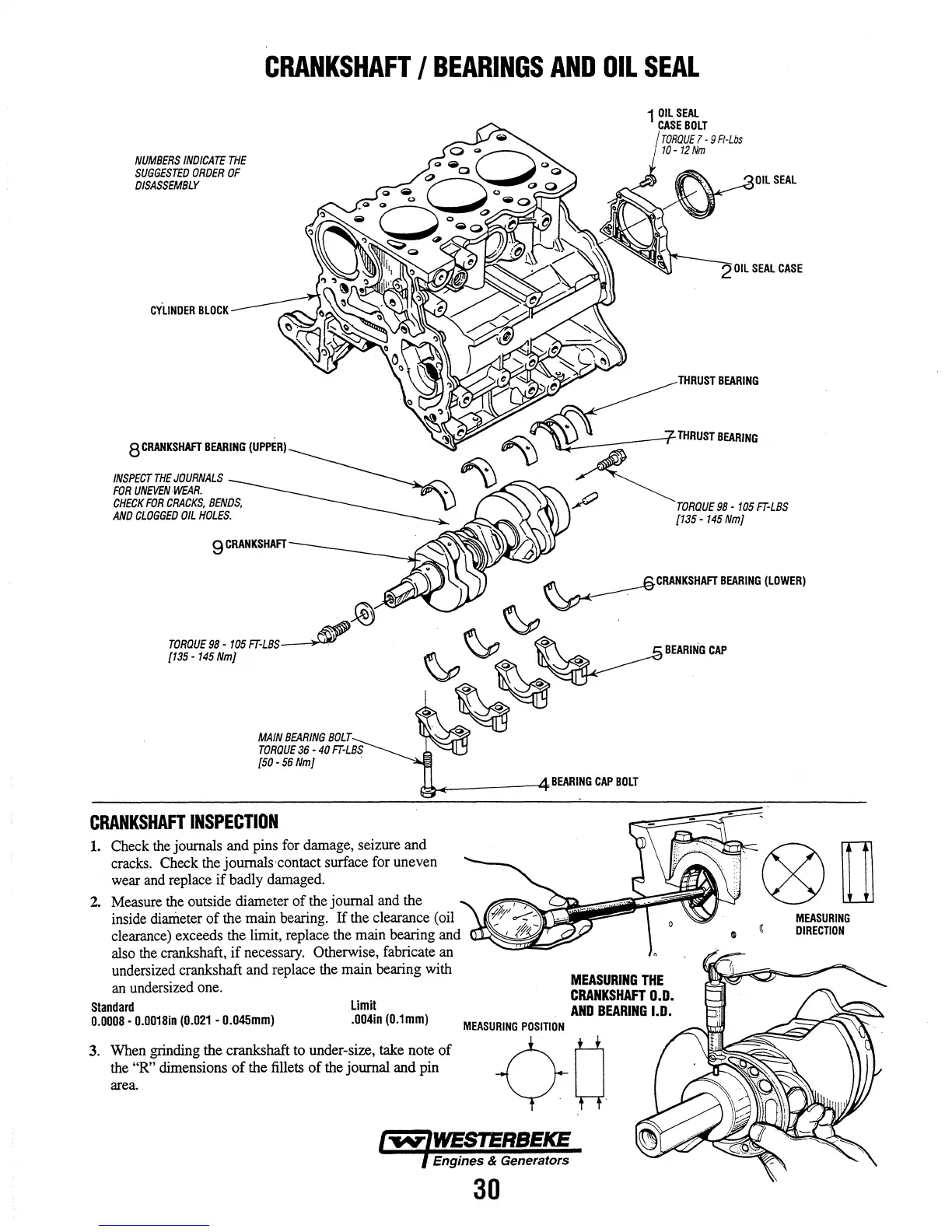

1.

Check the journals and pins for damage, seizure and

cracks. Check the joumalscontact surface for uneven

wear and replace

if

badly damaged.

2.

Measure the outside diameter

of

the journal and the

inside

dianieter

of

the main bearing.

If

the clearance (oil

clearance) exceeds the limit, replace the main bearing and

also the crankshaft,

if

necessary. Otherwise, fabricate an

undersized crankshaft and replace the main bearing with

an

undersized

one_

Standard

Limit

0.0008

-

0.0018in

(0.021

-

O_045mm)

.004in

(0_1mm)

3_

When grinding the crankshaft to under-size, take note

of

the "R" dimensions

of

the fillets

of

the journal and pin

area.

MEASURING

POSITION

MEASURING

THE

CRANKSHAFT

0.0.

AND

BEARING

1.0.

¢-w

Engines & Generators

30

II

MEASURING

DIRECTION

Loading...

Loading...