CRANKSHAFTI

BEARING

AND

OIL

SEAL

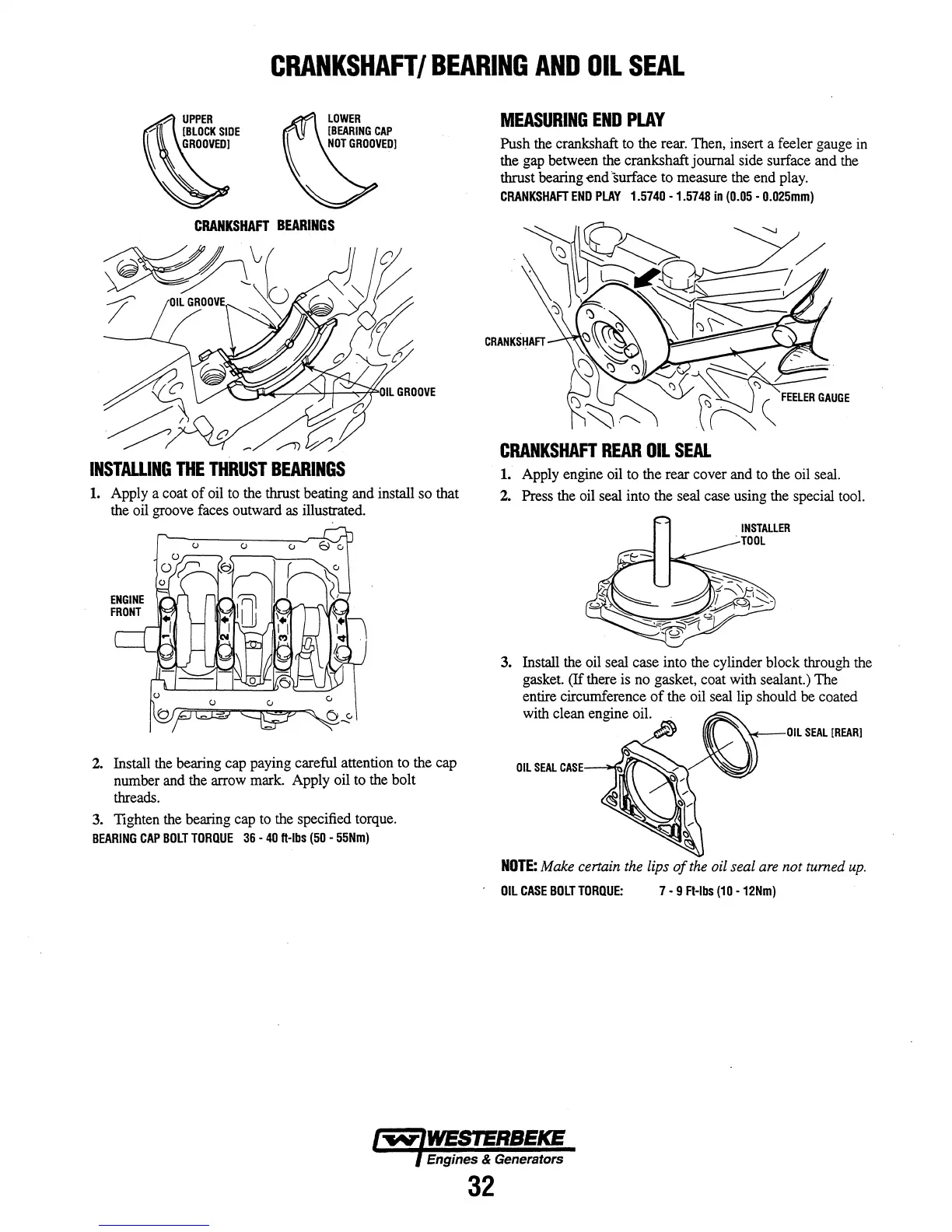

CRANKSHAFT

BEARINGS

INSTALLING

THE

THRUST

BEARINGS

1.

Apply a coat

of

oil to the thrust beating and install so that

the oil groove faces outward as illustrated.

2.

Install the bearing cap paying careful attention to the cap

number and the arrow mark. Apply oil to the bolt

threads.

3. Tighten the bearing cap to the specified torque.

BEARING

CAP

BOLT

TORQUE

36

-

40

ft-Ibs

(50

-

55Nm)

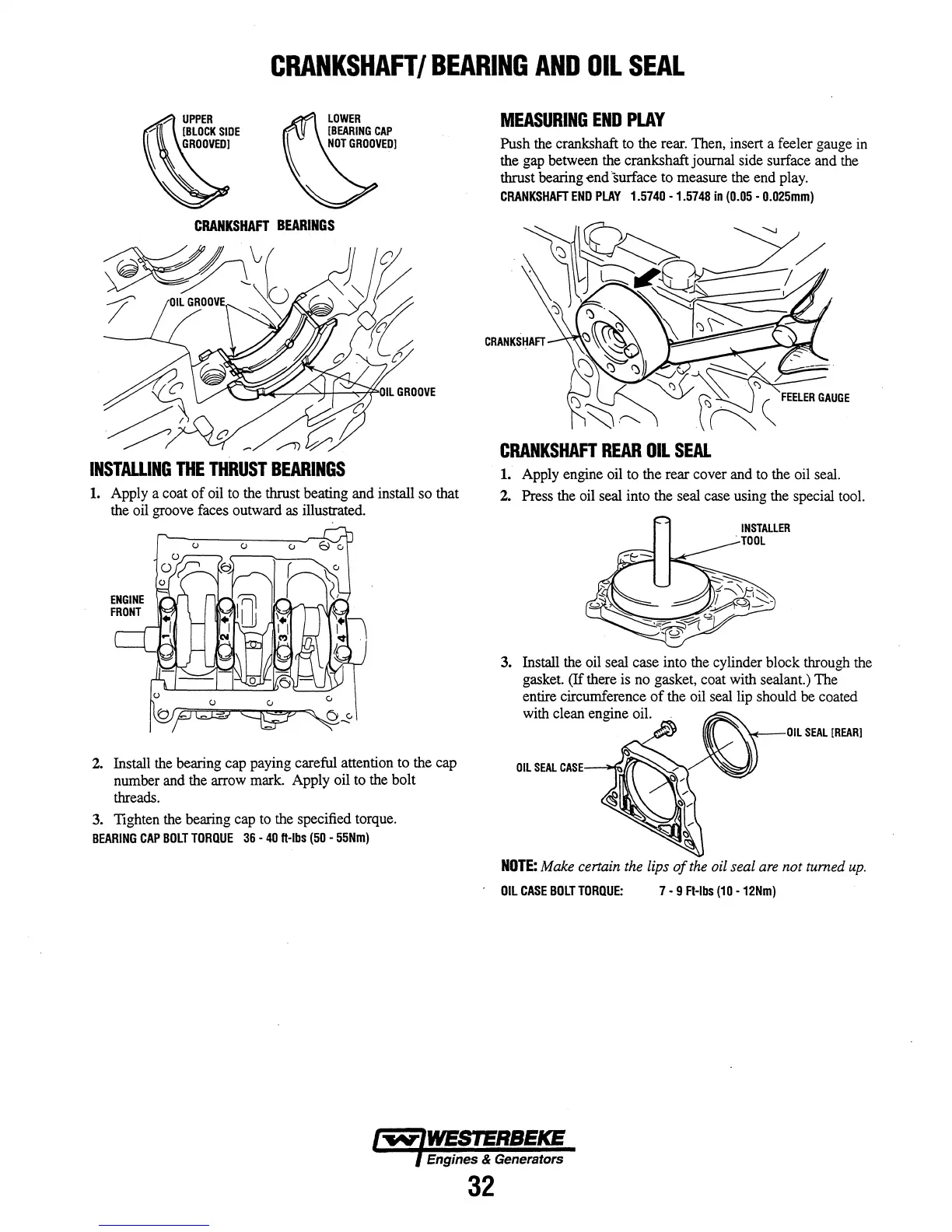

MEASURING

END

PLAY

Push the crankshaft to the rear. Then, insert a feeler gauge in

the gap between the crankshaft journal side surface and the

thrust bearing

end

surface to measure the end play.

CRANKSHAFT

END

PLAY

1.5740

-1.5748

in

(0.05

-

0.025mm)

CRANKSHAFT

REAR

OIL

SEAL

1. Apply engine oil to the rear cover and to the oil seal.

2. Press the oil seal into the seal case using the special tool.

3. Install the oil seal case into the cylinder block through the

gasket.

(If

there is no gasket, coat with sealant.) The

entire circumference

of

the oil seal lip should be coated

with clean engine oil.

OIL

SEAL

CASE

NOTE:

Make

certain

the

lips

of

the

oil seal

are

not turned

up.

OIL

CASE

BOLT

TORQUE:

7 - 9

A-Ibs

(10

-12Nm)

Engines & Generators

32

Loading...

Loading...