PISTONS

AND

CONNECTING

RODS

Installing

the

Connecting

Rod

Bearing

Caps

Since the connecting

rod

cap bolts and nuts are torqued

using the plastic area tightening method, the bolts should be

examined before reuse.

If

the bolt threads are "necked

down",

the bolt should be replaced.

Necking can be checked by running a nut with fingers to the

full length

of

the bolt threads.

If

the nut does not run

smoothly, the bolt should be replaced.

Before installation

of

each nut, apply clean engine oil to the

thread portion and bearing surface

of

the

nut

Install each nut to the bolt and tighten

it

with your fingers.

Then tighten the nuts alternately to install the cap properly.

Tighten the nuts to the proper torque.

CAP

NUT

TIGHTENING

TORQUE

11+90'

turn

(15Nm

+90'

tum)

A

CAUTION:

If

the

cylinder

head

has

been

installed

before

installing

the

connecting

rod

cap

nut,

remove

the

spatk

plugs.

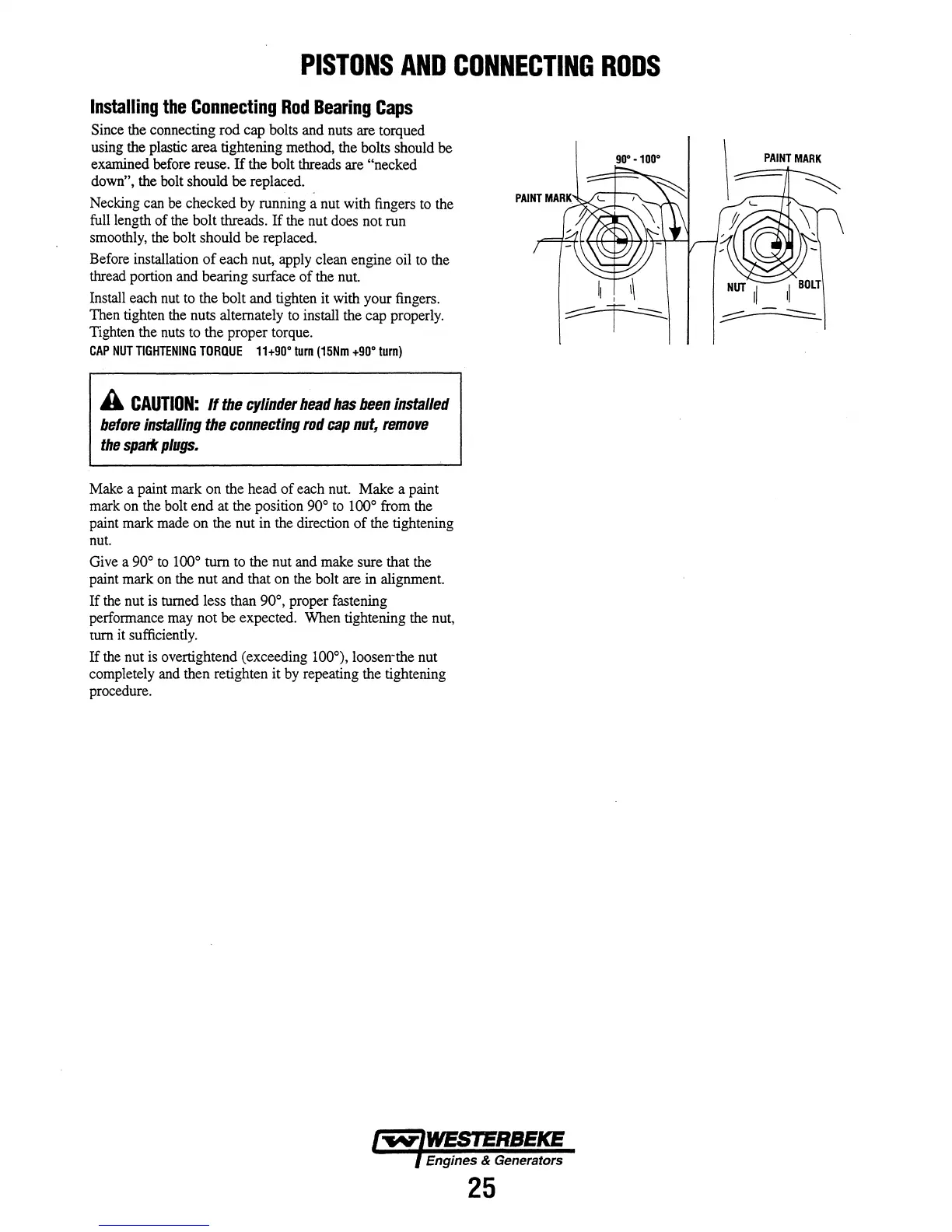

Make a paint mark

on

the head

of

each nut. Make a paint

mark on the bolt

end

at the position 90° to 100° from the

paint mark made on the nut in the direction

of

the tightening

nut.

Give a

90° to 100°

turn

to the nut and make sure that the

paint mark on the nut and that on the bolt are in alignment.

If

the nut is turned less than 90°, proper fastening

performance may not be expected. When tightening the nut,

rum it sufficiently.

If

the nut is overtightend (exceeding 100°), loosen-the nut

completely and then retighten it by repeating the tightening

procedure.

Engines & Generators

25

Loading...

Loading...