THERMOSTAT

ASSEMBLY

I

FUEL

PUMP

COOLANT

RECOVERY

TANK

Flush out

the

recovery

tank

and

the

hose

that connects

to

the

pressure

cap

assembly.

Use

a pipe cleaner or compressed air

to

clear the passage where the hose connects

to

the casting.

Also

clear the

by-pass

hose

fittings. Replace the plastic

tank

and

hose if it

fails

to

pass inspection.

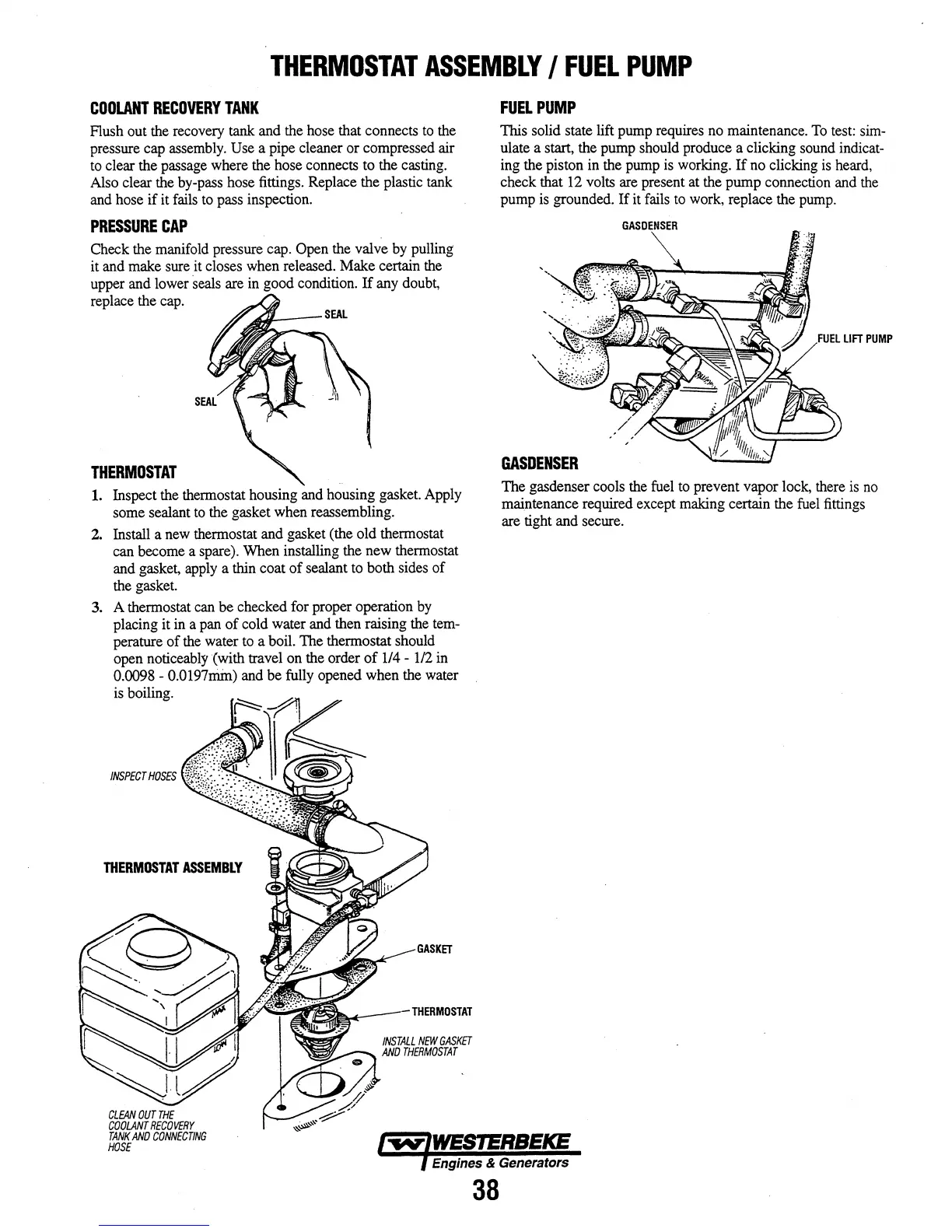

PRESSURE

CAP

Check the manifold pressure

cap.

Open

the

valve

by

pulling

it and

make

sure

it closes

when

released. Make certain

the

upper and lower seals

are

in

good condition.

If

any

doubt,

replace the

cap.

THERMOSTAT

1.

Inspect

the

thermostat housing

and

housing gasket.

Apply

some sealant

to

the gasket

when

reassembling.

2.

Install a

new

thermostat and gasket (the old thermostat

can

become a spare). When installing the new thermostat

and gasket,

apply

a thin coat of sealant

to

both sides of

the

gasket.

3.

A thermostat

can

be checked for proper operation

by

placing it

in

a

pan

of cold water

and

then raising

the

tem-

perature of

the

water

to

a boil. The thermostat should

open

noticeably

(with travel

on

the order

of

114

-

112

in

0.0098 - 0.0197niin)

and

be

fully

opened when the water

is

boiling.

THERMOSTAT

ASSEMBLY

CLEAN

OUT

THE

COOLANT

RECOVERY

TANK

AND

CONNECTING

HOSE

THERMOSTAT

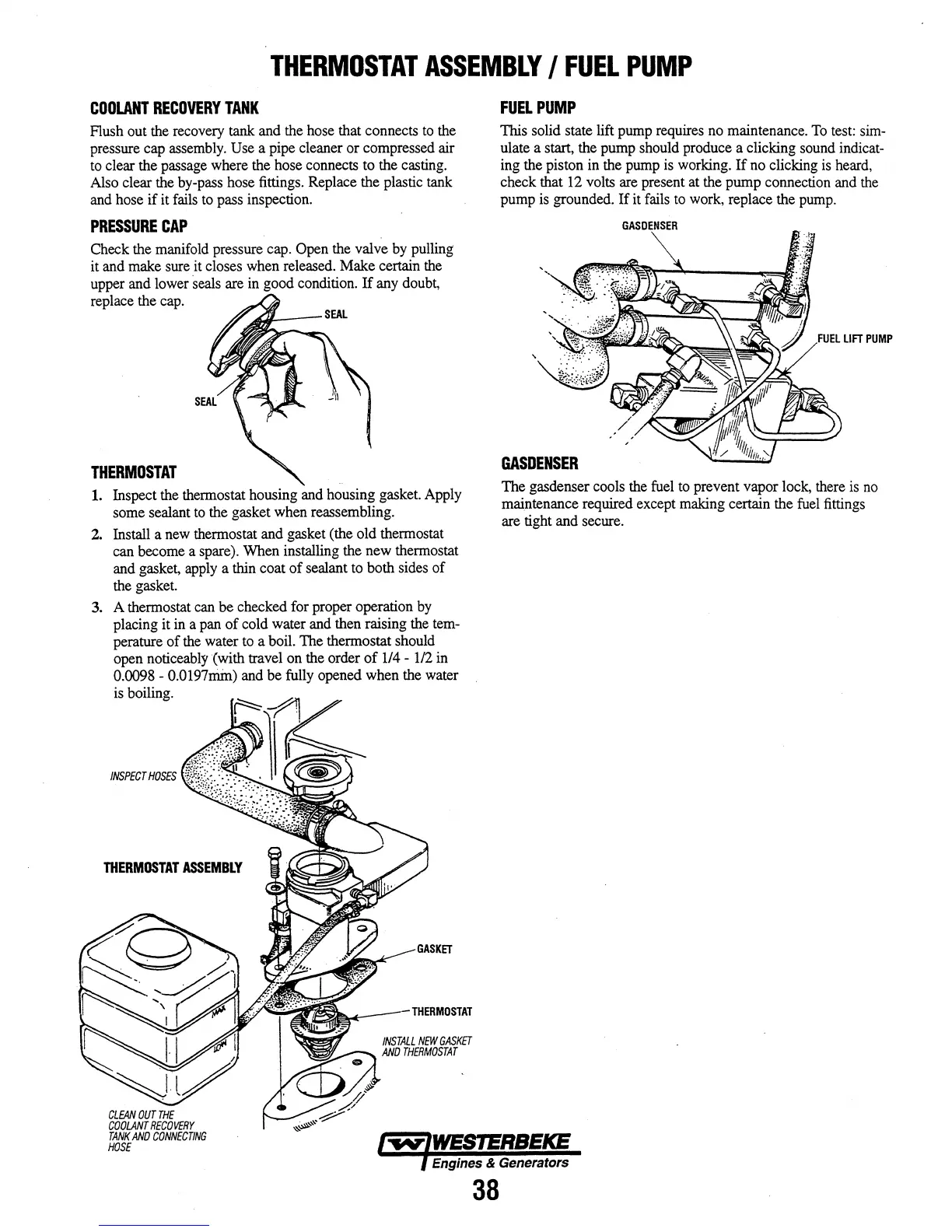

FUEL

PUMP

This solid state lift

pump

requires

no

maintenance.

To

test:

sim-

ulate a start, the

pump

should produce a clicking

sound

indicat-

ing

the piston in the

pump

is

working.

If

no

clicking

is

heard,

check that

12

volts

are

present

at

the pump connection

and

the

pump

is

grounded.

If

it

fails

to

work,

replace the

pump.

GASOENSER

FUEL

LIFT

PUMP

GASDENSER

The gasdenser cools

the

fuel

to

prevent vapor lock, there

is

no

mai.ntenance

required except making certain the

fuel

fittings

are

tight and secure.

Engines & Generators

38

Loading...

Loading...