STARTER

MOTOR

STARTER

INSPECTION

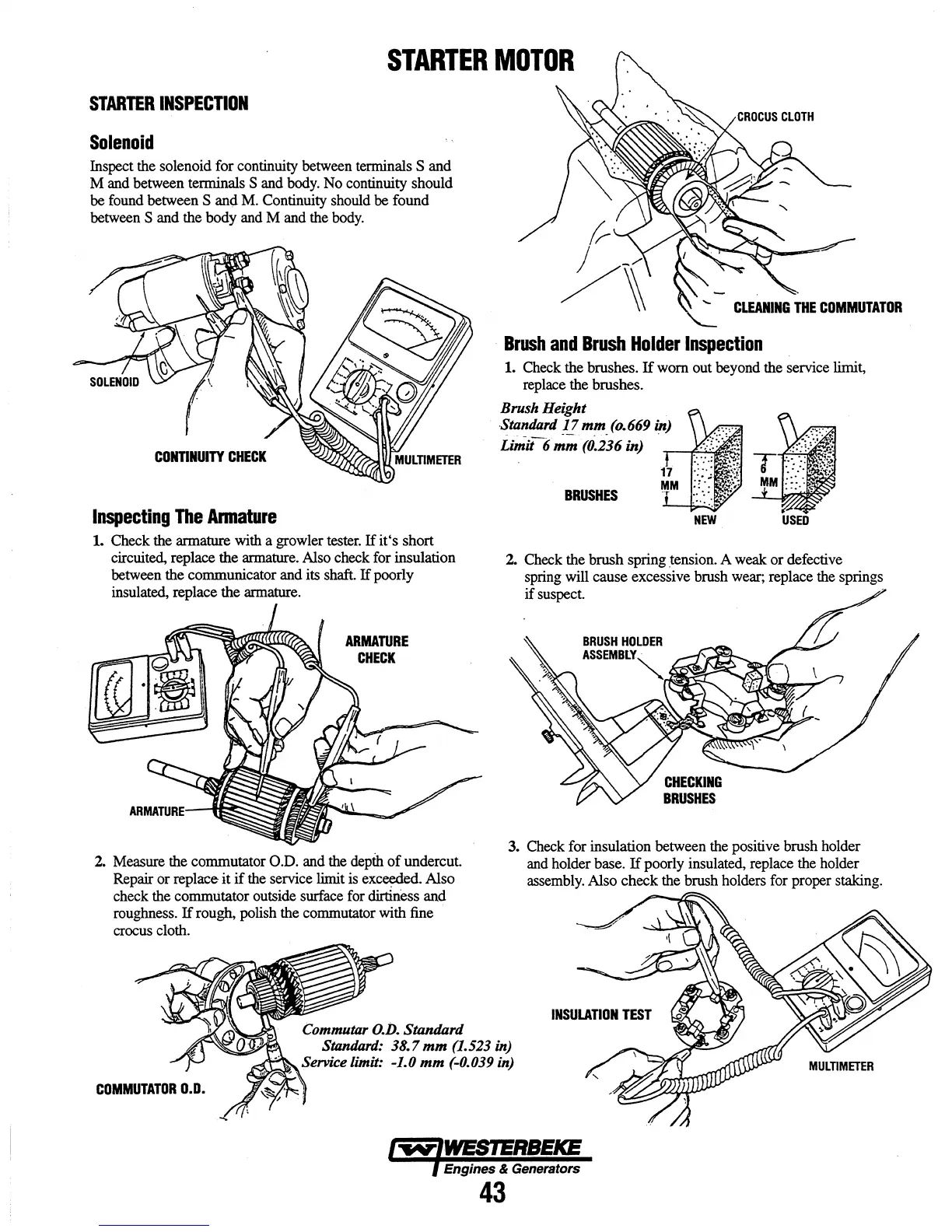

Solenoid

Inspect

the

solenoid for continuity between terminals S and

M

and

between terminals S and

body.

No

continuity should

be

found

between S an9

M.

Continuity should

be

found

between

S and the body

and

M

and

the

body.

COmNUllY

CHECK

Inspecting

The

Annature

1. Check

the

armature with a growler

tester.

If

it's short

circuited. replace the armature.

Also

check

for

insulation

between the communicator and its

shaft.

If

poorly

insulated, replace the

armature.

ARMATURE'--H~

ARMATURE

CHECK

2.

Measure

the

commutator

0.0.

and

the

depth

of undercut

Repair or replace it

if

the

service limit

is

exce¢ed. Also

check

the

commutator outside surface

for

dirtiness and

roughness.

If

rough. polish the commutator

with

fine

crocus

cloth.

,

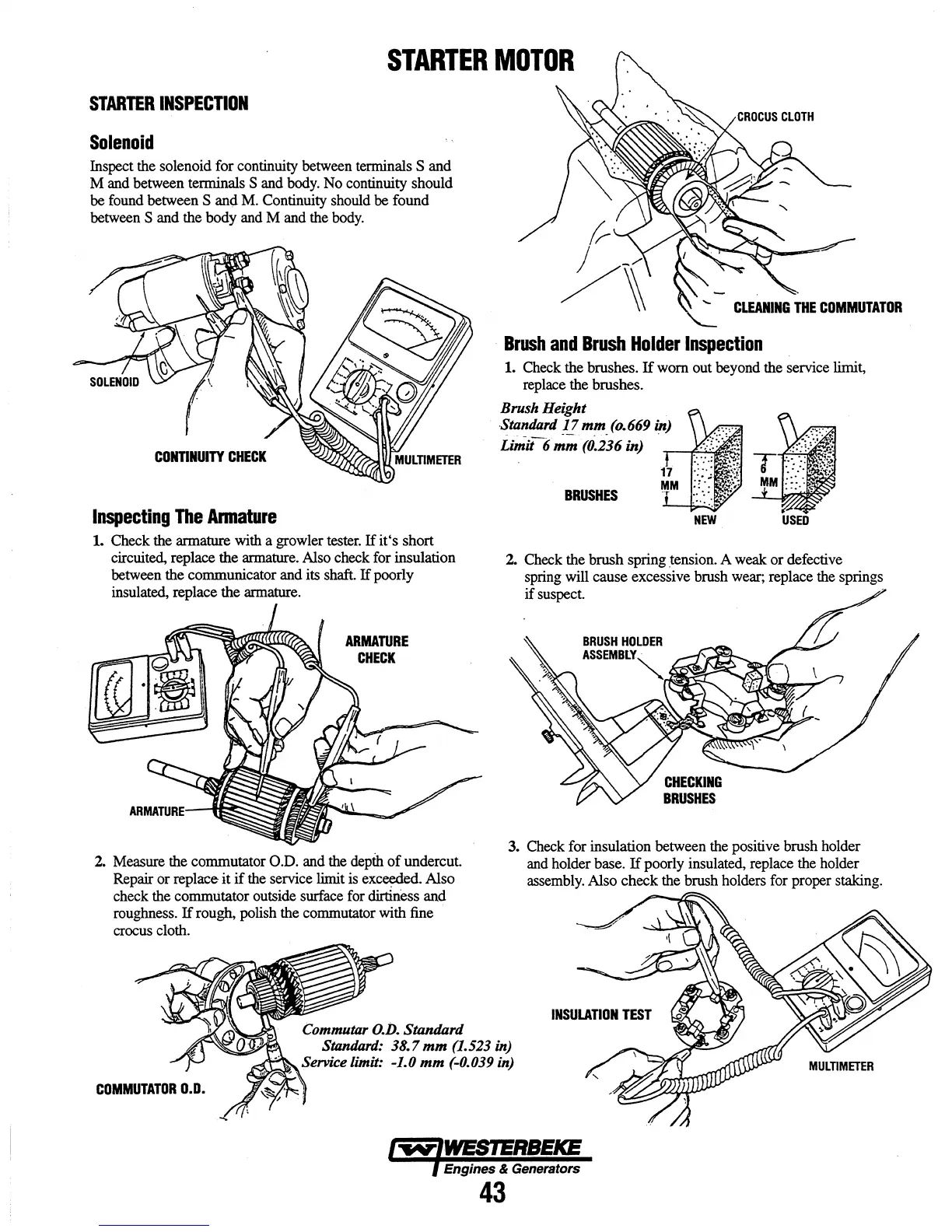

Brush

and

Brush

Holder

Inspection

1.

Check

the brushes.

If

worn

out beyond the service limit,

replace

the brushes.

Brush Height

, Standard

17

mm

(0.669 in)

iiinit6

,;;;" (O.i36 in) ,

,---~""4~1

BRUSHES

2.

Check

the brush spring

.tension.

A

weak

or defective

spring

will cause excessive brush

wear;

replace

the

springs

if

suspect.

.

BRUSH

HOLDER

ASSEMBLY

~

QIo2'~_"""

3.

Check

for insulation between

the

positive brush holder

and

holder base.

If

poorly insulated, replace

the

holder

assembly.

Also check

the

brush

holders

for

proper staking.

Commutar O.D.

Standard

Standard: 38.7

mm

(1.523 in)

E'V>.~~,Service

limit:

-1.0

mm

(-0.039 in)

COMMUTATOR

0.0.

j"""'WES7EllBEKE

I Engines & Generators

43

Loading...

Loading...