en Commissioning

80 WILO SE 2018-12

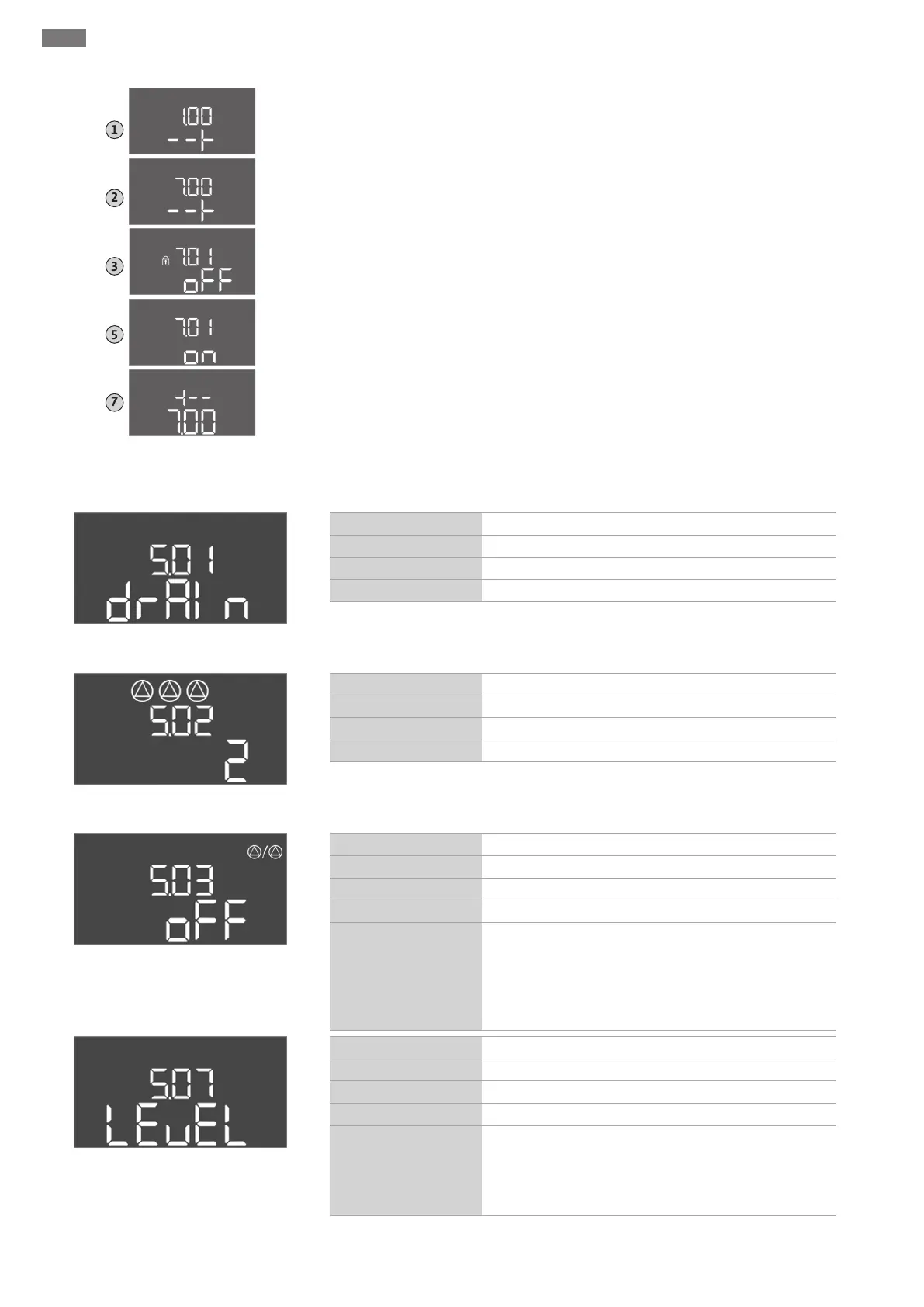

Fig.31: Parameter input enabled

1. Press the operating button for 3s.

⇒ Menu item 1.00 appears

2. Turn the operating button until menu 7 appears.

3. Press the operating button.

⇒ Menu 7.01 appears.

4. Press the operating button.

5. Change value to “on”: Turn the operating button.

6. Save value: Press the operating button.

⇒ The menu is enabled and can be changed.

7. Turn the operating button until the end of menu 7 appears.

8. Press the operating button.

⇒ Back to the main menu level.

▶ Start initial configuration:

– Menu 5: Basic settings

– Menu1: Switch-on/off values

– Menu2: Field bus connection (if applicable)

- Menu 3: Enable pumps

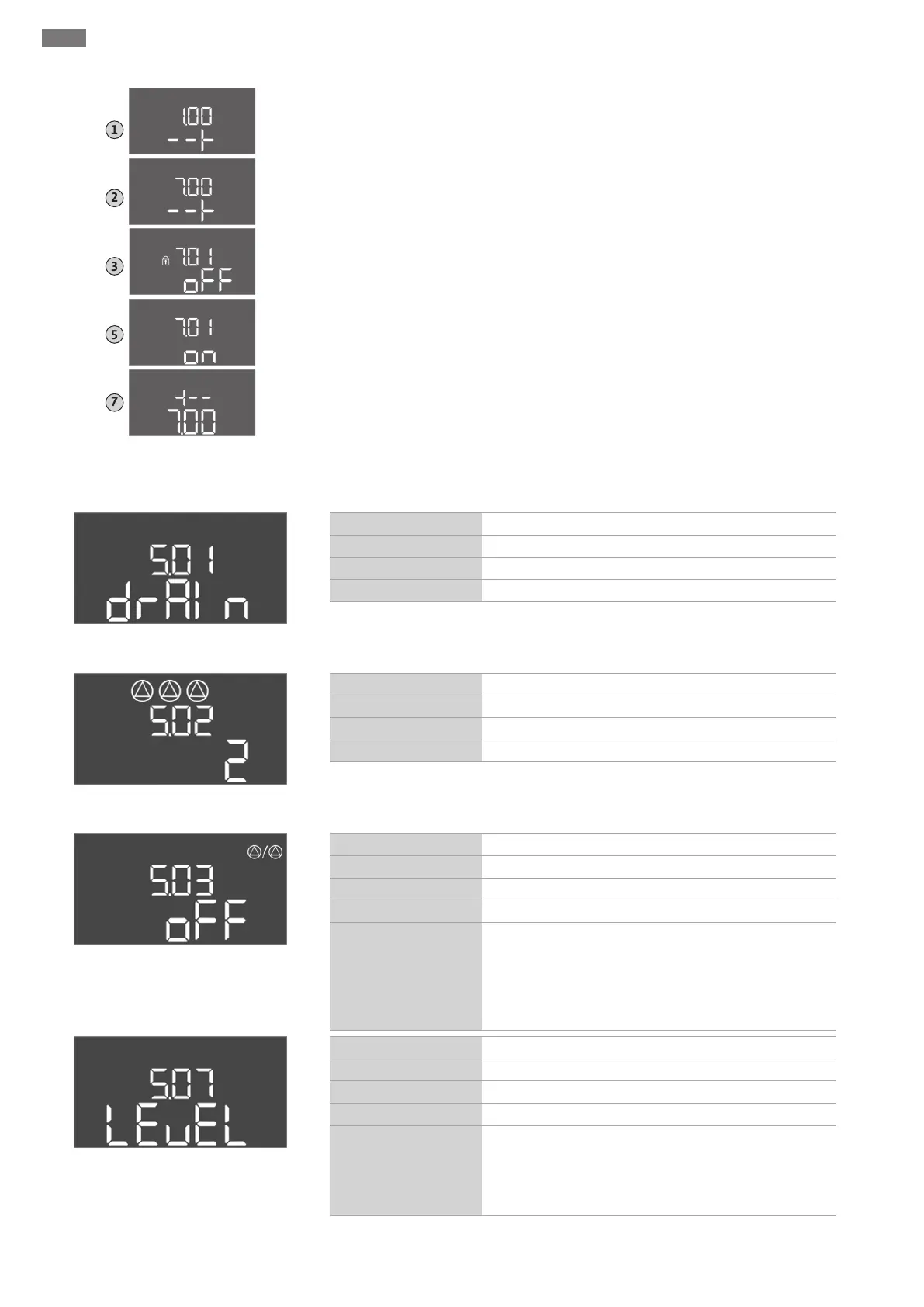

Menu 5: Basic settings

Fig.32: Menu 5.01

Menu no. 5.01

Description Operating mode

Value range fill (fill), drain (drain)

Factory setting drain

Fig.33: Menu 5.02

Menu no. 5.02

Description Number of connected pumps

Value range 1 … 3

Factory setting 2

Fig.34: Menu 5.03

Menu no. 5.03

Description Standby pump

Value range on, off

Factory setting off

Explanation

One pump can be used as the standby pump. This pump is

not activated in normal operation. The standby pump is

only activated in the event of pump failure due to a fault.

The standby pump is subject to standstill monitoring. The

standby pump is therefore activated during pump cycling

and pump kick.

Fig.35: Menu 5.07

Menu no. 5.07

Description Signal transmitter for level measurement

Value range Float, Level, Bell, Opt01

Factory setting Level

Explanation

Definition of the signal transmitters for level measurement:

- Float = float switch

- Level = level sensor

- Bell = dynamic pressure bell

- Opt01 = NW16 level monitor

Loading...

Loading...