en Maintenance and repair

92 WILO SE 2018-12

4. Seal threaded cable connections watertight.

5. Support the switchgear (e.g. get a second person to help).

6. Loosen the switchgear fastening screws and remove the switchgear from the

structure.

▶ Switchgear removed. Observe the following for storage!

10 Maintenance and repair

DANGER

Risk of death due to electrocution!

Improper conduct when carrying out electrical work can lead to death due to electric

shock! Electrical work must be carried out by a qualified electrician in accordance

with the locally applicable regulations.

NOTICE

Unauthorised work or structural changes are prohibited!

Only maintenance and repair work described in this manual may be carried out. All

other works and any alterations to the construction may only be carried out by the

manufacturer.

10.1 Maintenance intervals

Regular

▪Clean switchgear.

Annually

▪Check electro-mechanical components for wear.

After 10 years

▪General overhaul

10.2 Maintenance tasks

Cleaning switchgear

‡ Switch off switchgear.

1. Clean switchgear with a damp cotton cloth.

Do not use any aggressive or scouring cleaners or fluids!

Check electro-mechanical components for wear

Get electro-mechanical components (e.g. contactor combinations) checked for wear by

an electrician. If wear is ascertained, have the affected components replaced by an

electrician or Wilo Customer Service.

General overhaul

During a general overhaul, all of the components, wiring and the housing are checked

for wear. Defective or worn components are replaced.

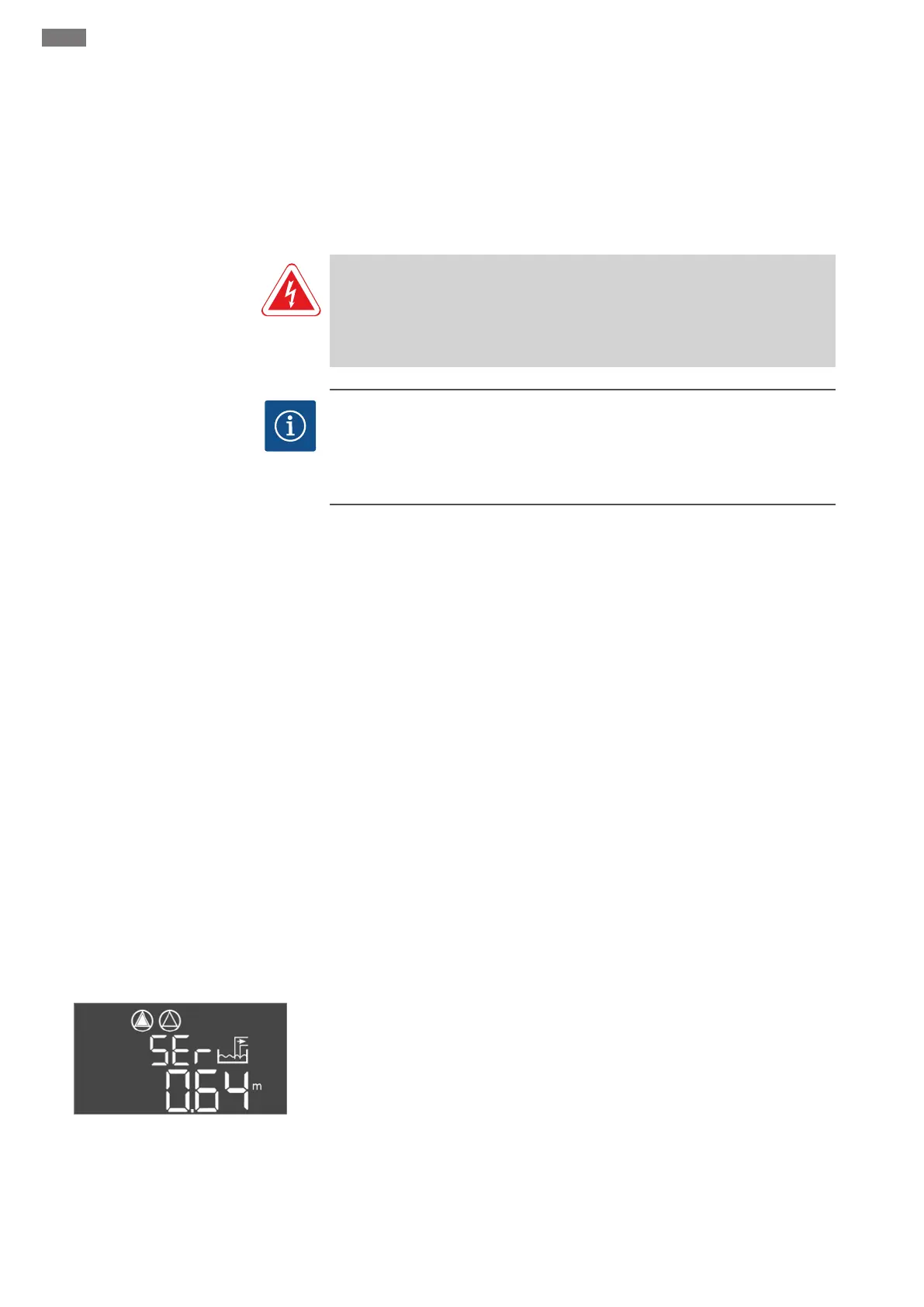

10.3 Maintenance interval display

Fig.72: Maintenance interval display

The switchgear has an integrated maintenance interval indicator. Once the set interval

has expired, “SER” on the main screen blinks. The next interval starts automatically by

resetting the current interval. The function is disabled at the factory.

Loading...

Loading...