10.2.8 Miscellaneous malfunctions (XX45NN to XX52NN)

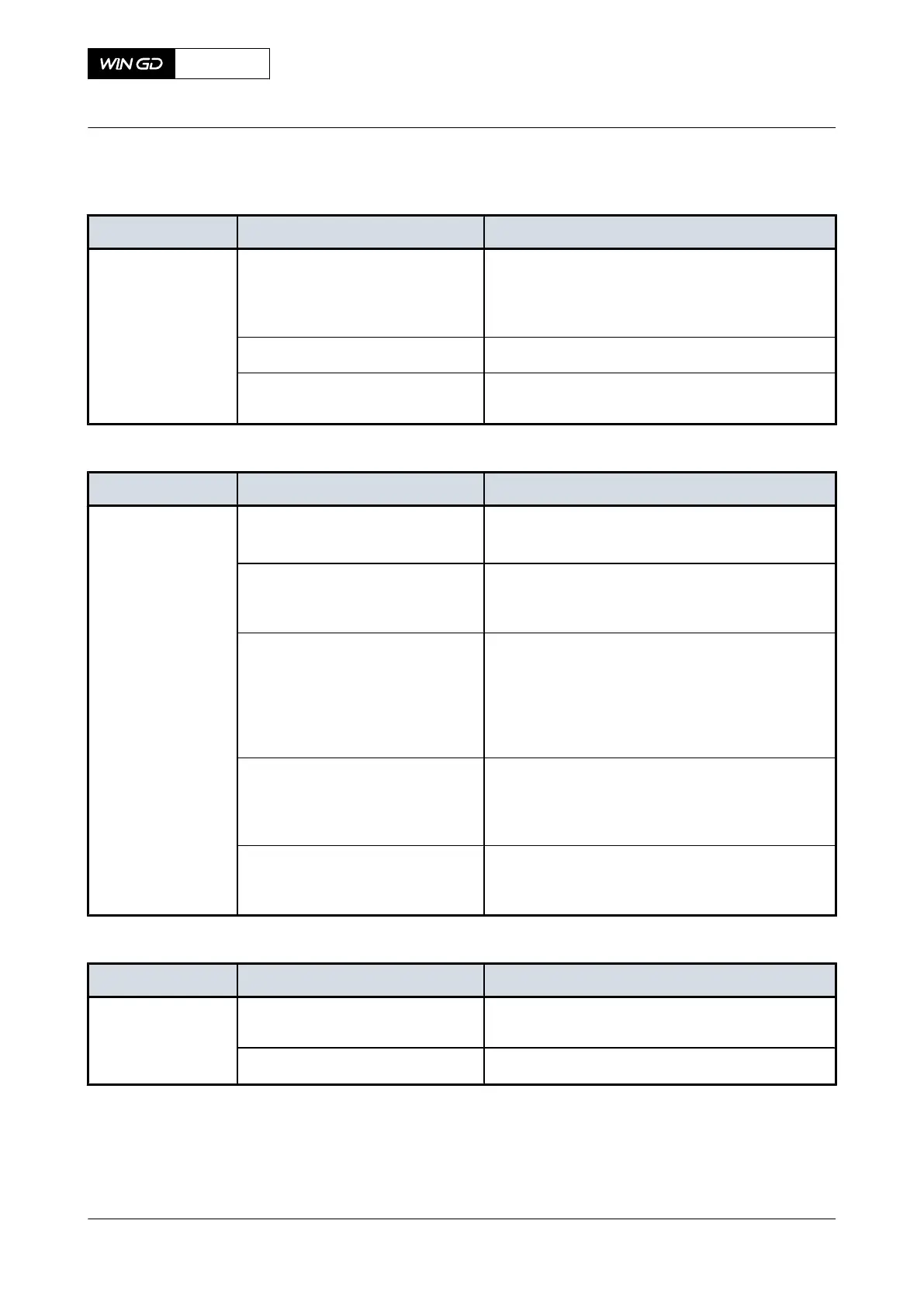

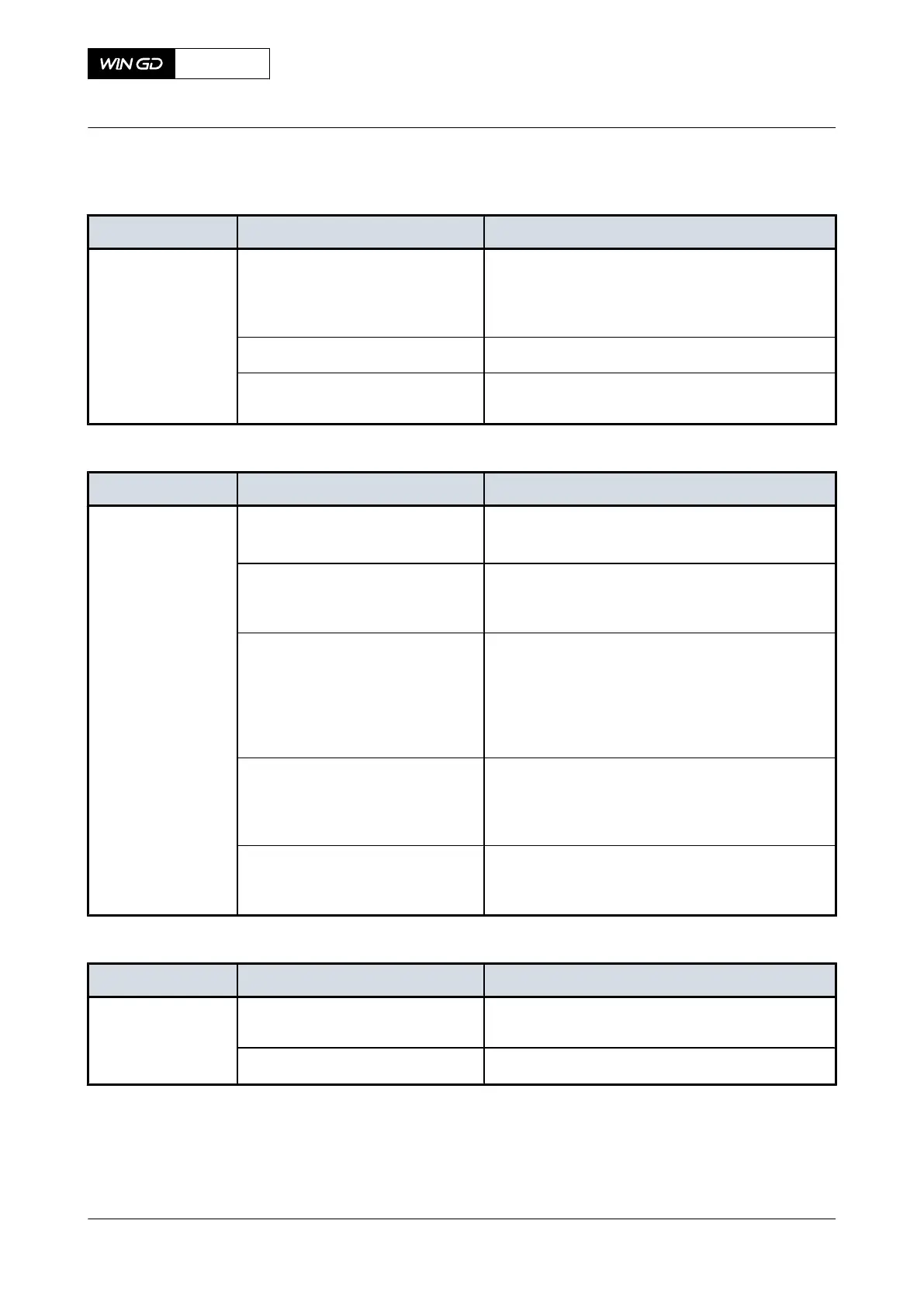

Tab 10-57 Temperature of a thrust bearing pad is too high

Indication Possible cause Procedure

TE4521A This is a result of the malfunction in

Table 10-7 - Lubricating oil supply

pressure at the engine inlet is too

low

•

Do the repair shown there.

The thrust bearing is defective

•

Find the cause and repair the fault.

The oil does not have the specified

properties

•

Use correct oil.

Tab 10-58 Cylinder liner wall temperature is too high

Indication Possible cause Procedure

TE4801-nnC

TE4841-nnC

The cylinder oil system is defective

•

Find the cause and repair the fault.

An injection nozzle is defective (for

example wrong spray angle, too

long spray period)

•

Repair or replace the defective injection

nozzle.

This is a result of the malfunction in

Table 10-1 - Supply pressure of the

cylinder cooling water is too low or

in Table 10-3 - Cylinder cooling wa-

ter temperature downstream of a

cylinder is too high

•

Do the repair shown there.

There is air in the cooling water

system

•

Release the unwanted air from the cooling

water system, for an engine with bypass

cooling water system refer to section [sec-

tion not applicable for this engine].

There are exhaust gas leaks into

the cooling water system (for ex-

ample valve seat area)

•

Find the cause and repair the fault.

Tab 10-59 A fuel pump actuator has a failure

Indication Possible cause Procedure

XS5046A The fuel does not have the speci-

fied properties

•

Use correct fuel.

A fuel pump actuator is defective

•

Repair the fuel pump actuator.

X92-B

AA00-0000-00AAA-410C-A

Operation Manual Malfunctions of systems and components

Winterthur Gas & Diesel Ltd.

- 335 - Issue 002 2021-11

Loading...

Loading...