63

3062547_201802

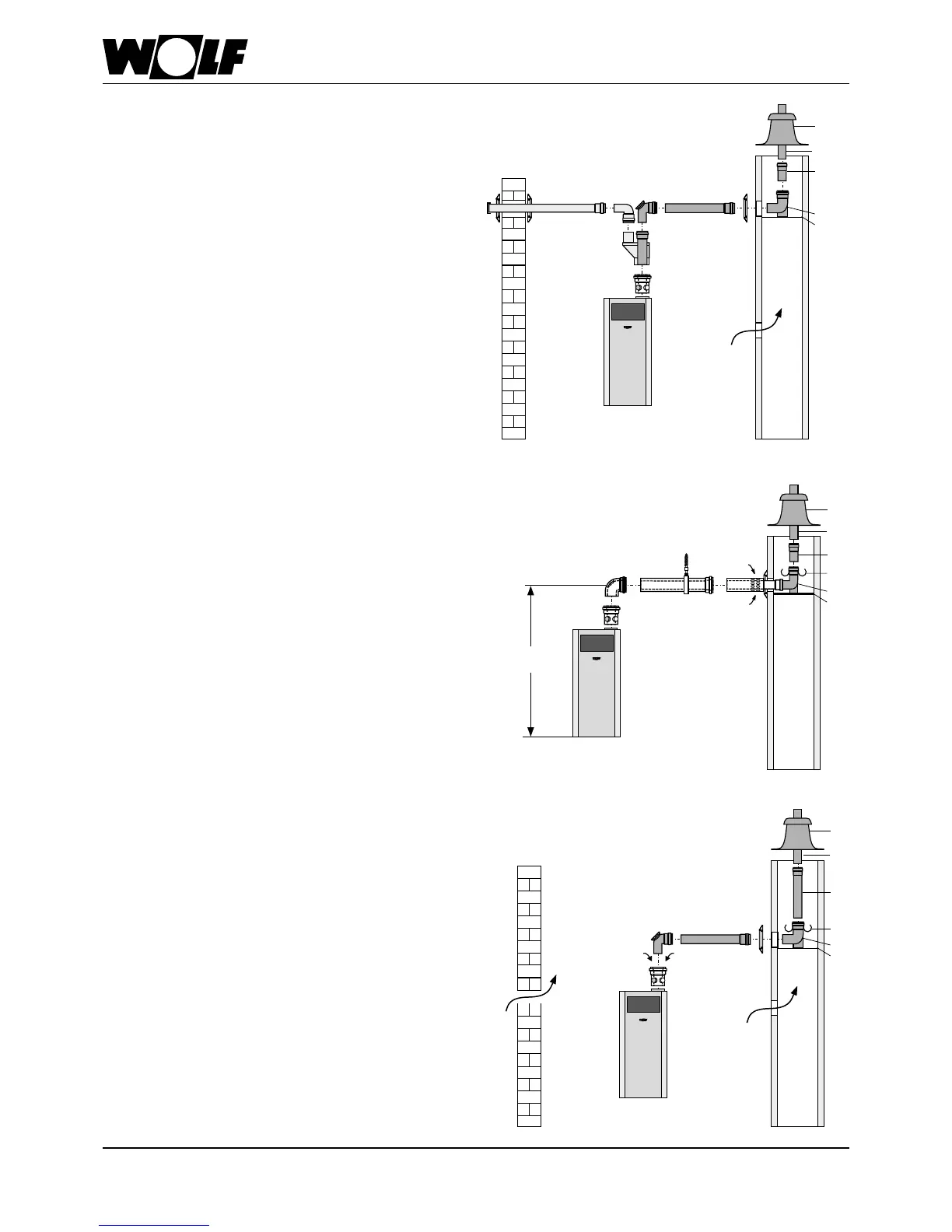

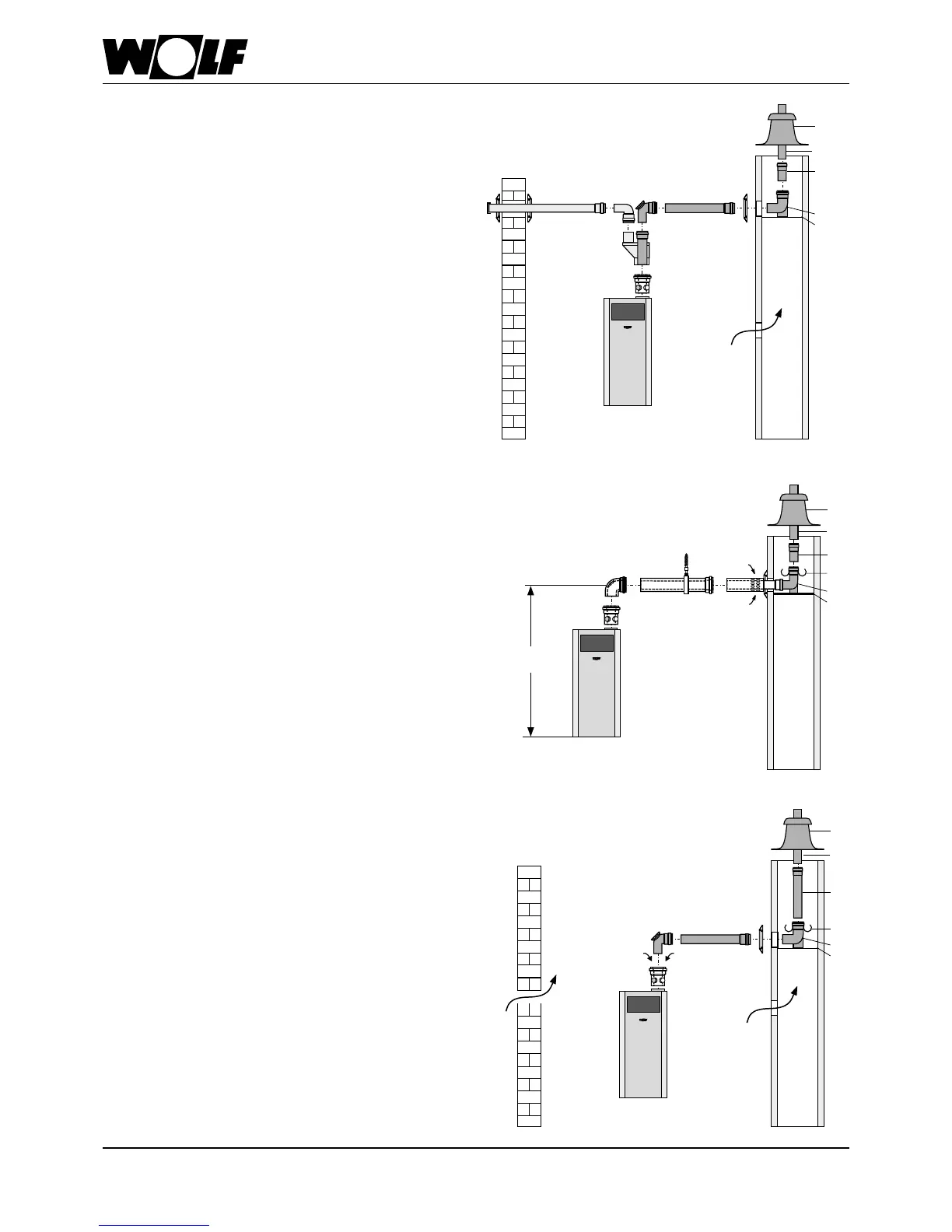

B23openuesystemandB33(example)

DN60/100,DN80/125andDN110/160

1 Oilcondensingboiler

2 Connectionadaptorwithtestnipple

for air and ue gas

(included in COB standard delivery)

4 Balancedue

500 mm

1000 mm

2000 mm

5 Spacerclip (only if required)

10 87°inspectionpiece

16 Pipecollar

22 Connection to

B33uechimney

250 mm length with air intake

23 supportrail

24 87°supportbend

25 Spacer

26 PPuepipe

500 mm

1000 mm

2000 mm

27 Shaftcover

29 Balanceduedistributor

30 Airintakepipe

31 Bend 87°

32 87°bendwithinspectionport

33 PP outlet

Install the balanced ue distributor 29 mm excentrically (29) for

separate balanced ue on the oil condensing boiler.

Install the horizontal ue with a fall of approx. 3° (6 cm/m) towards

the boiler. Route the horizontal air supply with a 3° fall towards

the outside – install the air inlet with wind protection; permissible

wind pressure at the air inlet 90 Pa. The burner will not operate

with higher wind pressure.

Excentric,room-sealedueC53(example)

DN 80 and DN 110

B23

B33

approx. 1500 mm (COB-15/20/29)

approx. 1700 mm (COB-40)

C53

Loading...

Loading...