Operation

6720813171 (2015/04)32

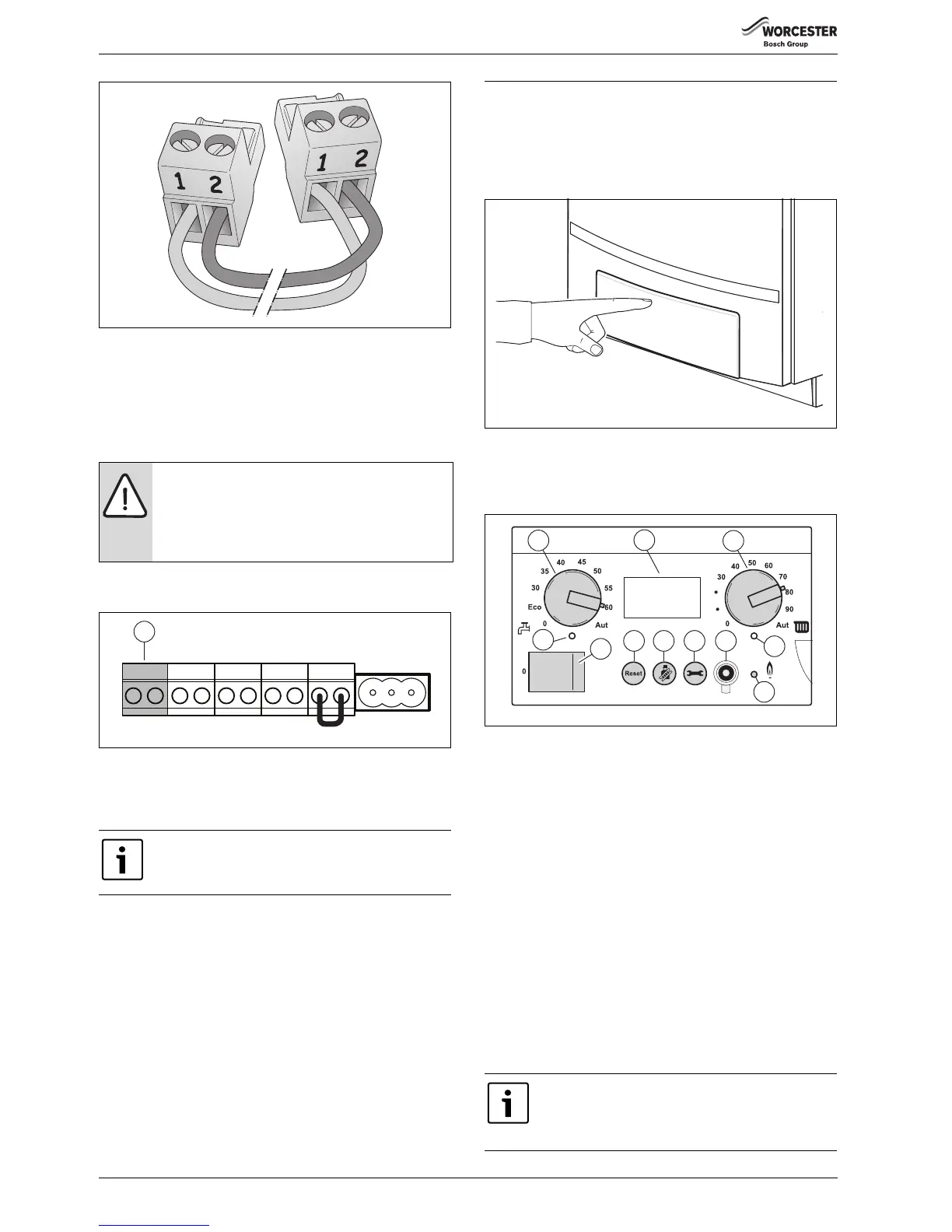

Fig. 66 EMS bus polarity

Installing and connecting function modules outside the boiler

▶ Install the module on the wall.

▶ Make a sufficiently long EMS bus connection cable, using a 2-core

cable of 0.4 - 0.75 mm² and the connector enclosed with the module

( fig. 66). Important: Use the connector of the same colour as the

connections on the module.

▶ Connect the EMS bus connection cable to the orange connection of

the terminal strip [1].

Fig. 67 Terminal strip - Room controller RC and EMS bus (connection

colour orange)

▶ Connect the other end of the EMS bus connection cable to the first

module ( fig. 65).

▶ If more modules are used, the EMS bus connection for the second

module may be branched off from the first module using the cable

enclosed with the module.

▶ Connect the EMS bus connection lead of the first module to the next

module ( fig. 65).

▶ Make a sufficiently long 230 VAC mains cable, using a 3-core cable of

at least 0.75 mm² with an earthing wire, the connector enclosed with

the module and a 230 VAC earthed plug.

▶ Connect the 230 VAC mains cable to the module ( fig. 65). If more

modules are used, the 230 VAC supply to the next module can be

branched off from the previous module using the connector enclosed

with the module and a 3-core 0.75-mm² current cable with an

earthing wire.

▶ Connect the 230 VAC supply cable of the previous module to the

next module ( fig. 65).

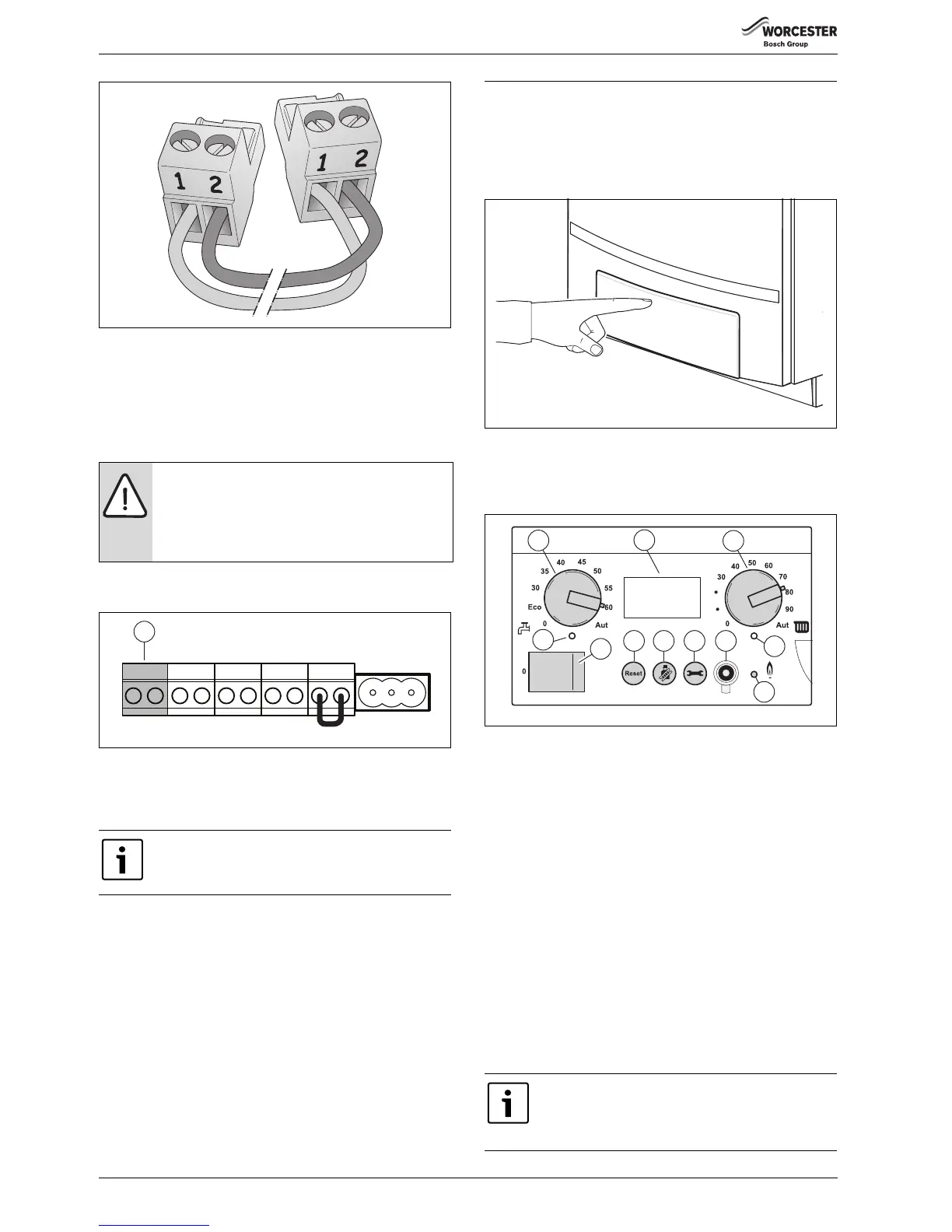

9Operation

9.1 General items

The boiler is fitted with a control unit, the BC10 basic controller.

This controller can be used to control the heating system.

▶ Push on the control panel to open it.

Fig. 68 Opening the control panel

The BC10 basic controller is located on the left, behind the door

( fig. 1, [4]).

The BC10 basic controller consists of the following components:

Fig. 69 BC10 basic controller

[1] Mains switch

[2] “Reset” button

[3] “Chimney sweep” button

[4] “Service button”

[5] Service Connector

[6] “Burner” LED (On/Off)

[7] “Heat demand” LED

[8] Maximum CH flow temperature dial

[9] Display

[10] DHW temperature dial

[11] “DHW mode” LED

Mains switch

The mains switch [1] is used to switch the boiler on and off.

“Reset” button

If a fault has occurred you may have to restart the boiler by pressing the

“Reset” button [2]. This is only required in the event of a “locking” fault.

“Blocking” faults are reset automatically as soon as their cause has been

corrected. The display shows [\/r/e| during the reset operation.

NOTICE:

Pay attention to the polarity when using an EMS bus

connection cable.

▶ Connect the wire from terminal 1 to terminal 1 and

from terminal 2 to terminal 2 ( fig. 65 and 66).

The module may have the letters RC or EMS above the

connection ( fig. 65, [1]).

Loading...

Loading...