Maintenance

6720813171 (2015/04)48

12.12 Inspection log book

▶ Enter your signature and the date after completing the inspection activities.

13 Maintenance

▶ Prepare the system for maintenance as described in the chapter on

Inspection ( section 12.1, page 46).

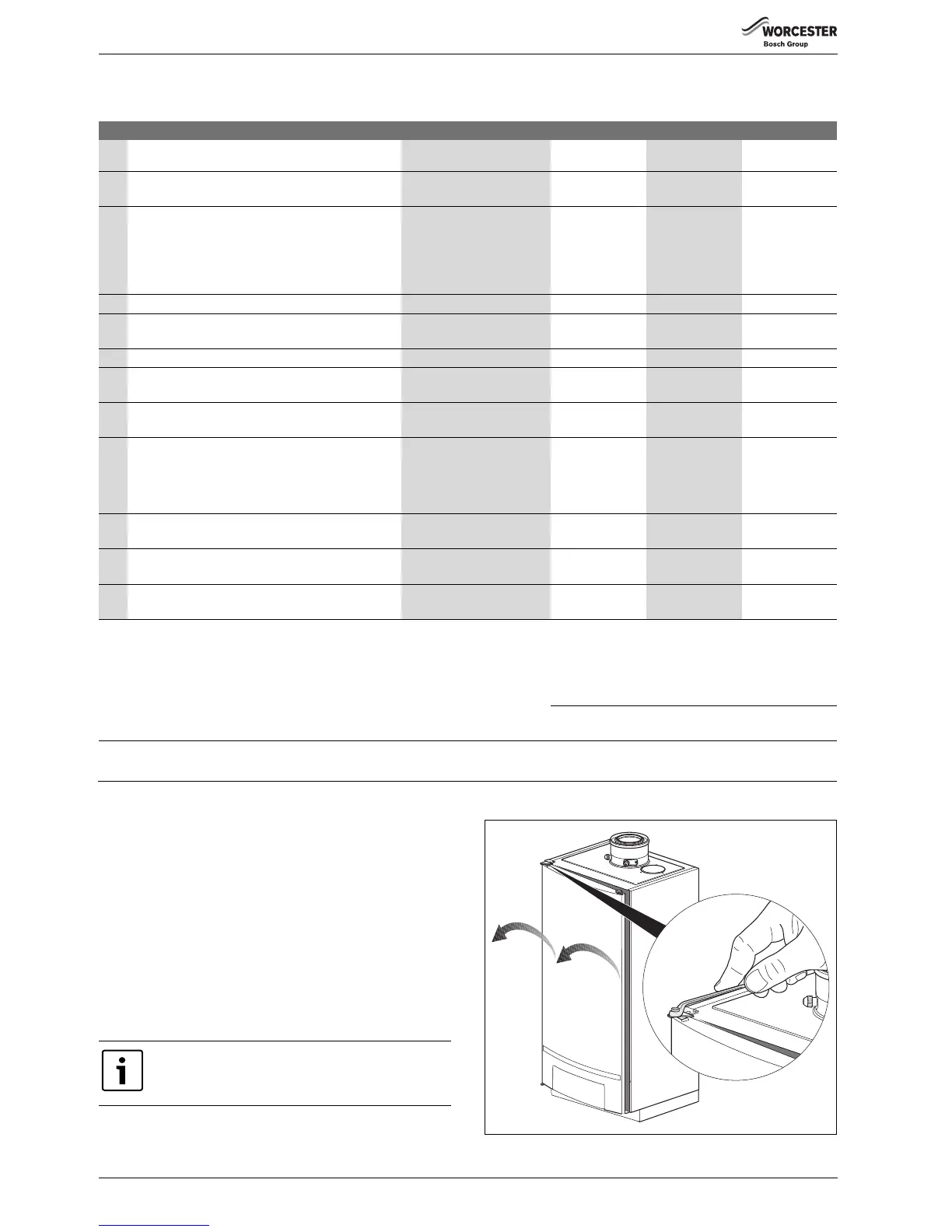

13.1 Removing the boiler door

If the boiler door cannot be fully opened, it may be necessary to remove

the door for inspection and maintenance activities.

Proceed as follows:

▶ Unscrew the control panel from the boiler door and hang it on the

boiler frame ( fig. 119 “Undoing the screws”, page 53).

▶ Unscrew the bolt from the left-hand top hinge of the boiler door and

remove it together with the washer.

▶ Slightly lift the door and pull it from the hinge. Put the door upright in

a safe position and make sure that it cannot fall over.

Fig. 103 Removing the boiler door

Inspection activities Date: ________ Date: ________ Date: ________

1. Checking the general condition of the heating system.

2. Carrying out a visual inspection and function test of

the heating system.

3. Checking the gas and water-bearing system

components for:

• Operational tightness

• Visible corrosion

• Signs of wear.

Section 10.2.8, page 42.

Section 12.3, page 47.

4. Measuring the ionisation current. Section 10.2.11, page 43. ___________ μA ___________ μA ___________ μA

5. Measuring the gas supply pressure (working

pressure).

Section 10.2.6, page 40. ________ mbar ________ mbar ________ mbar

6. Checking the gas/air-ratio. Section 10.2.7, page 40. _________ Pa _________ Pa _________ Pa

7. Carrying out a tightness check of the gas circuit in

operating conditions.

Section 10.2.8, page 42.

8. Measuring the carbon monoxide content (CO), air

free.

Section 10.2.9, page 43. _________ ppm _________ ppm _________ ppm

9. Checking the system pressure.

• Pre-pressure of expansion vessel (also see

installation instructions for expansion vessel)

•Filling pressure.

Section 10.1, page 37.

_________ bar

_________ bar

_________ bar

_________ bar

_________ bar

_________ bar

10. Checking the operation and safety of the air intake and

flue gas pipe.

Section 10.2.4, page 40.

11. Checking the boiler settings of the control device (in

accordance with requirements).

See the documents for the

control device.

12. Final check of the inspection activities, documenting

the measurement and test results.

13. Confirming proper inspection.

Company stamp/

signature/date

Company stamp/

signature/date

Company stamp/

signature/date

Table 20

The cover over the electrical connections does not have

to be removed from the boiler.

Loading...

Loading...