Commissioning

6720813171 (2015/04) 41

▶ Press and hold the “Chimney sweep” button [3] (approximately 2

seconds), until the dot in the right-hand bottom corner of the display

[9] appears. See also table 10, “Flue gas test”, page 34.

▶ After the “Burner” LED [6] has lit up wait for one minute until the

boiler is burning at full load.

▶ Measure the gas supply pressure and enter it in the commissioning

log book, page 72.

The gas supply pressure must be:

• for natural gas H min. 17 mbar, max. 25 mbar, nominal supply

pressure 20 mbar.

• for LPG min. 30 mbar, max. 50 mbar, nominal supply pressure

37 mbar.

▶ Press the “Service” button [4] repeatedly until the temperature

reading is shown in the display.

▶ Press the “Chimney sweep” button [3] to clear the reading. Also see

table 10, “Flue gas test”, page 50.

Fig. 86 BC10 basic controller

▶ Close the gas valve ( fig. 81, page 39).

▶ Remove the gauge-connection tube and tighten the screw plug on the

testing nipple again.

▶ Open the gas valve again by pushing on the gas valve and turning it ¼

rotation in an anticlockwise direction ( fig. 79, page 39).

10.2.7 Checking and adjusting the gas/air-ratio

▶ Open at least 2 thermostatic radiator valves. Do not switch on the

boiler.

▶ Push on the control panel to open it ( fig. 68, page 32).

▶ Switch off the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 86, [1]).

▶ Close the gas valve ( fig. 81, page 39).

▶ Turn the vent key through a quarter rotation to undo the boiler door

lock ( fig. 71, see detailed picture, page 37).

▶ Push the fastener down and open the boiler door ( fig. 71,

page 37).

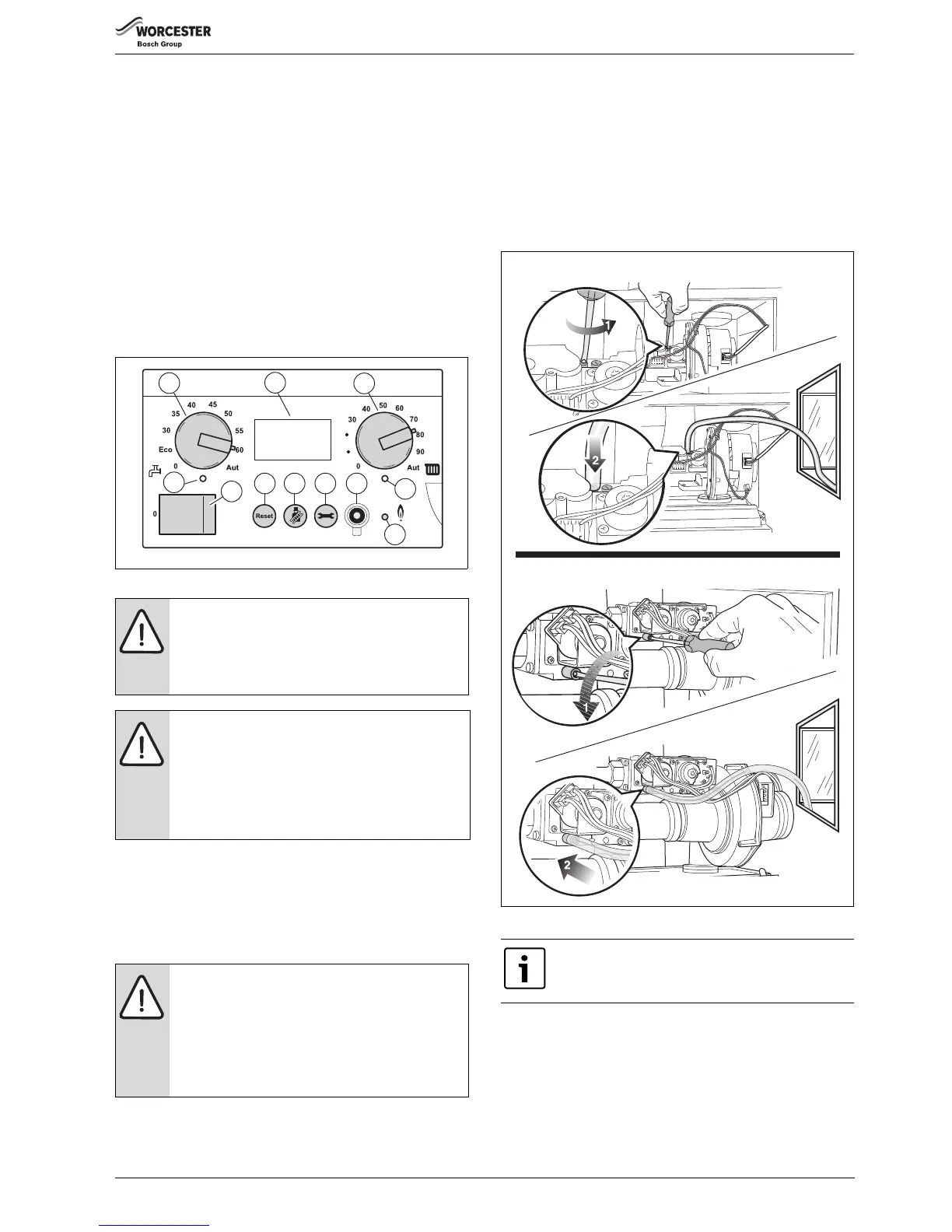

▶ Open the screw plug on the testing nipple for the burner pressure by

2 turns [1].

▶ Set the pressure gauge to “0”.

Fig. 87 Checking the gas/air ratio

▶ Use a connection tube to connect the positive port of the pressure

gauge to the testing nipple for burner pressure ( fig. 87, [2]).

▶ Slowly open the gas valve by pushing on the gas valve and turning it

¼ rotation in an anticlockwise direction ( fig. 79, page 39).

▶ Switch on the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 86, [1]).

▶ Activate the Service mode in accordance with the “Service mode”

menu ( table 11, page 34).

DANGER: Danger of fatal accident from explosive

fumes.

▶ Check the testing nipples used for leaks.

▶ Only use approved leak detection spray to locate

leaks.

NOTICE:

▶ Check the gas supply pipe or contact the relevant gas

utility company if the required supply pressure is not

available.

▶ If the supply pressure is too high, a gas pressure

regulator must be integrated upstream of the gas

fitting. Contact the gas utility company.

WARNING:

Damage to the boiler by incorrect adjustment of the gas/

air-ratio.

▶ Adjust gas/air-ratio only with part load.

▶ Adjust gas/air-ratio only based on the gas/air

pressure differential and never based on measured

flue gas values such as CO/CO

2

/NO

x

.

Loading...

Loading...