Maintenance

6720813171 (2015/04)52

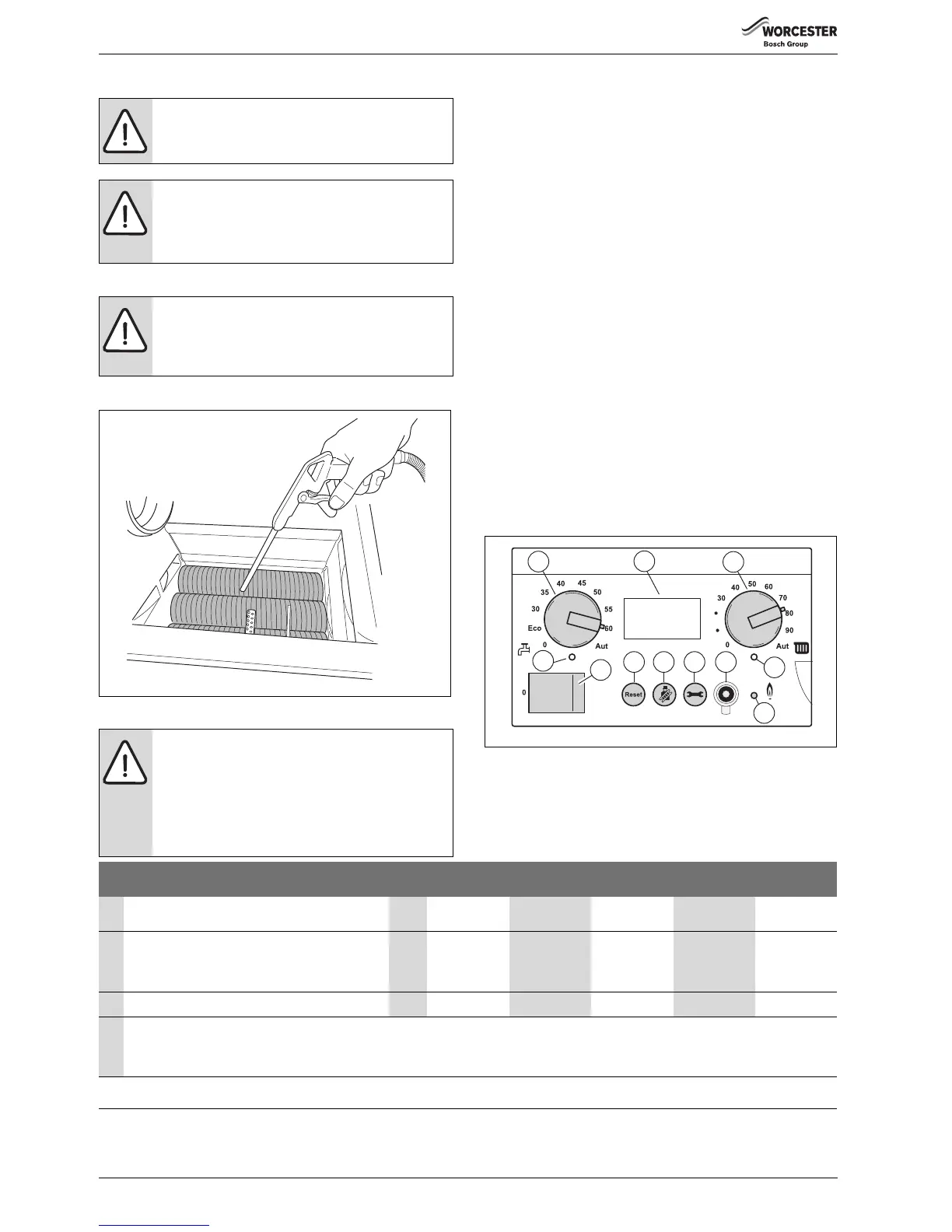

13.2.7 Cleaning the heat exchanger

▶ Check the bottom and top sides of the heat exchanger for dirt.

▶ Clean the heat exchanger with compressed air or a soft brush.

Fig. 117 Cleaning the heat exchanger

▶ Refit the condensate collector.

▶ Connect the flexible condensate drain hose to the condensate

collector.

▶ Re-install the condensate trap.

▶ Rinse the heat exchanger with clean water.

▶ Reassemble all boiler components in reverse order:

– Burner with burner seal

– Burner cover with fan and gas valve

– Gas valve

– Glow ignitor and ionisation electrode.

▶ Start up the boiler ( chapter 10 “Commissioning”, page 37).

13.3 Checking and adjusting the gas/air-ratio

See section 10.2.7 “Checking and adjusting the gas/air-ratio”, page 41.

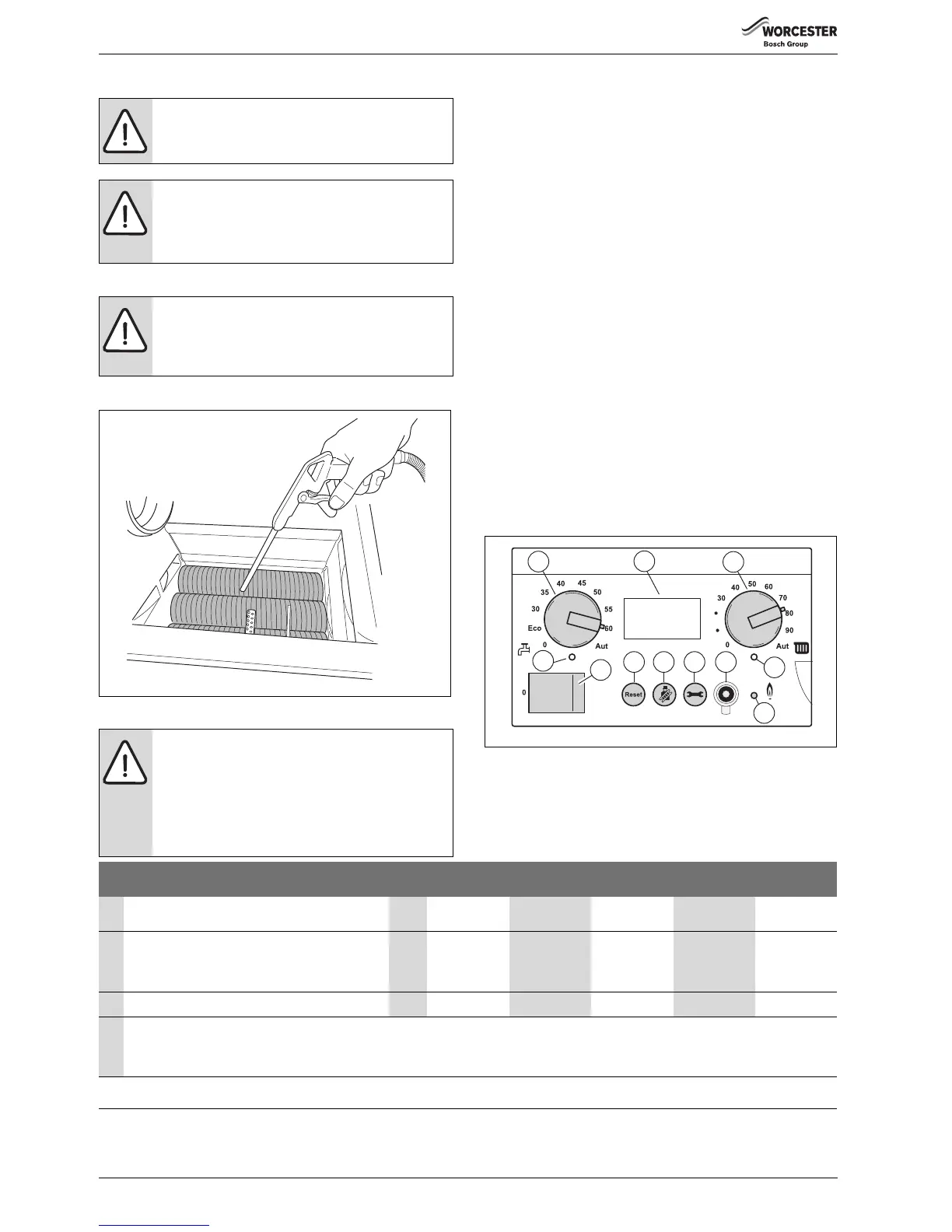

13.4 Function check in operating conditions

▶ Slowly open the gas valve by pushing on the gas valve and turning it

¼ rotation in an anticlockwise direction ( fig. 79, page 39).

▶ Switch on the heating system by pressing the mains switch of the

BC10 basic controller [1].

▶ Set the maximum CH flow temperature dial [8] and the DHW

temperature dial [10] to the maximum temperatures.

▶ Enter a heat demand via the control unit and check that the boiler

starts the heating mode.

▶ Open a hot water tap and check that the boiler starts the DHW mode.

▶ Set the maximum CH flow temperature dial [8] and the DHW

temperature dial [10] to the required temperatures.

Fig. 118 BC10 basic controller

13.5 Service record log book

Complete the log book while carrying out needs-oriented maintenance.

▶ Enter your signature and the date after completing the maintenance

activities.

CAUTION: Damage to the installation.

▶ Do not use metal brushes or similar hard cleaning

tools.

CAUTION: Damage to the installation due to faulty glow

ignitor.

The glow ignitor is made from fragile ceramic material.

▶ Do not damage the glow ignitor.

CAUTION: Damage to the installation due to dirt

particles.

▶ Cover up the boiler interior, e. g. using a blanket or a

cover.

CAUTION: Damage to the installation due to undesired

flue gas or condensate leakage.

▶ When installing the condensate collector, make sure

that the 2 snap closures close smoothly. If this is not

the case, the seal between the condensate collector

and the flue pipe at the back of the heat exchanger

may be leak.

Loading...

Loading...