Commissioning

6720813171 (2015/04)40

10.2.4 Checking the flue gas connection

Check the following points:

• Has the prescribed flue gas system been used ( section 8.4 “Flue

gas connection”, page 23)?

• Have the configuration instructions from the relevant flue gas system

installation instructions been observed?

• Ensure all flue system connections made correctly. Has the annual

CO

2

and NO

x

, clearance to combustible materials been measured?

Have the permissible maximum length limit values from the flue gas

system installation instructions been observed?

10.2.5 Checking the appliance configuration

The burner must only be put into use with the right injectors

( table 14).

Fig. 83 Checking the gas classification label

10.2.6 Measuring the gas inlet pressure (working pressure)

▶ Open at least 2thermostatic radiator valves. Do not switch on the

boiler.

▶ Push on the control panel to open it ( fig. 68, page 32).

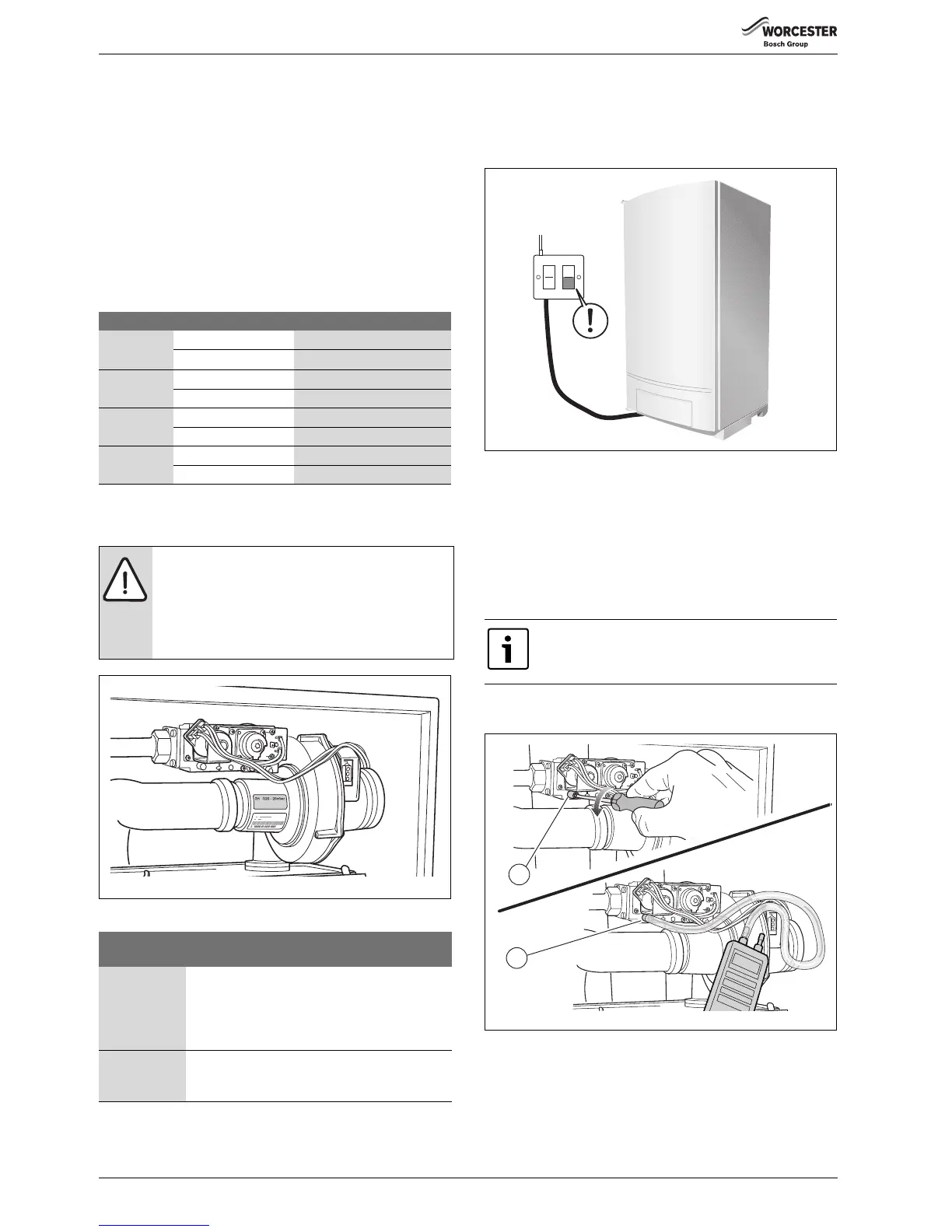

▶ Switch off the power supply to the heating system ( fig. 90).

Fig. 84 Switch off the power supply to the heating system

▶ Close the gas valve in a clockwise direction ( fig. 81, page 39).

▶ Turn the vent key through a quarter rotation to undo the boiler door

lock ( fig. 71, see detailed picture, page 37).

▶ Push the fastener down and open the boiler door ( fig. 71,

page 37).

▶ Open the screw plug on the testing nipple for the gas hook-up

pressure and for purging by 2 turns [1].

▶ Reset the digital pressure gauge to “0”.

▶ Connect the pressure gauge connection tube to the positive port of

the testing nipple [2].

Fig. 85 Measuring the gas supply pressure

▶ Slowly open the gas valve by pushing on the gas valve and turning it

¼ rotation in an anticlockwise direction ( fig. 79, page 39).

The gas valve is open when it is in the vertical position.

▶ Switch on the heating system by pressing the mains switch [1] of the

BC10 basic controller.

Boiler Type of gas supply Gas injector diameter [mm]

GB162-50 Natural gas H Venturi

1)

1) Check the gas classification label on the Venturi.

LPG 3P 5.3

GB162-65 Natural gas H Venturi

LPG 3P

5.3

GB162-80 Natural gas H 8.4

LPG 3P

4.7

GB162-100 Natural gas H 8.4

LPG 3P 4.7

Table 14 Gas injector diameter

NOTICE:

▶ Consult the relevant gas utility company for the type

of gas supply.

▶ Check that the actual gas supply is in accordance with

the type of gas supply specified on the gas

classification label ( fig. 83).

Type of gas

supply

Factory presetting for the gas burner

Natural gas H Delivered ready for operation, adjusted to Wobbe

index 14.1 kWh/m³ (with reference to 15 °C,

1013 mbar), applicable to Wobbe index range 12.7

to 15.2 kWh/m³. Markings on gas classification

label: Configured category: G 20 – 2H.

LPG 3P After adaptation by a Gas Safe registered installer,

the unit can be run on LPG.Markings on gas

classification label: Configured category: G 31 – 3P.

Table 15 Factory presetting for the gas burner

Loading...

Loading...