Commissioning

6720813171 (2015/04)42

▶ Set the capacity to minimum (part load) according to the “Service

mode” menu ( table 11, page 34).

▶ After the “Burner” LED ( fig. 86, [6]) has lit up wait for one minute

until the boiler is burning at part load.

▶ Read the differential pressure during service mode. The differential

pressure (p

gas

- p

air

) must be –5 Pa (±5 Pa) (indication on the

pressure gauge: –10 to 0 Pa).

Fig. 88 Gas/air difference at low load

▶ Enter the result in the commissioning log book ( section 10.5

“Commissioning record log book”, page 45).

▶ If the gas/air-ratio is incorrect, it must be adjusted on the set screw

(Torx 40 H) [1]. The set screw is located behind the screw-on cover.

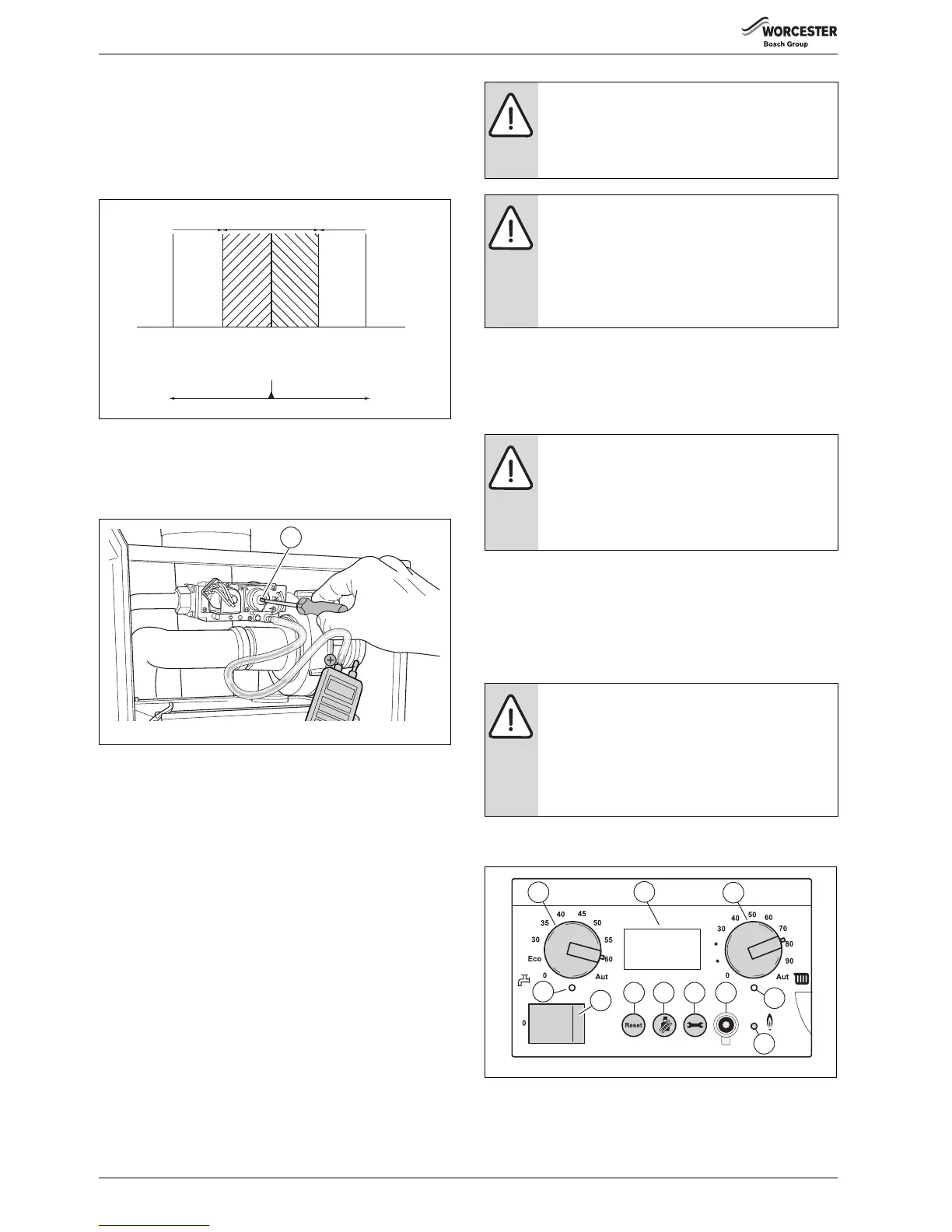

Fig. 89 Gas/air difference at low load

▶ Press the “Chimney sweep” button ( fig. 86, [3]) until the dot

disappears from the display.

▶ Switch off the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 90, [1]).

▶ Close the gas valve ( fig. 81, page 39).

▶ Remove the measuring devices.

▶ Tighten the screw in the burner pressure measuring nipple.

▶ Slowly open the gas valve by pushing on the gas valve and turning it

¼ rotation in an anticlockwise direction ( fig. 79, page 39).

▶ Switch on the heating system by pressing the mains switch of the

BC10 basic controller ( fig. 90, [1]).

▶ Press and hold the “Chimney sweep” button ( fig. 90, [3])

(approximately 2 seconds), until the dot in the right-hand bottom

corner of the display ( fig. 90, [9]) appears. See also table 10,

“Flue gas test”, page 34.

▶ After the “Burner” LED ( fig. 90, [6]) has lit up wait for one minute

until the boiler is burning at full load.

▶ Press the “Chimney sweep” button ( fig. 90, [3]) to clear the

reading. See also table 10, “Flue gas test”, page 34.

▶ Check that the boiler performance is still at the required value. See

table 13 “Settings”, page 36.

10.2.8 Carrying out a leakage test in operating conditions

▶ Press and hold the “Chimney sweep” button [3] (approximately 2

seconds), until the dot in the right-hand bottom corner of the display

[9] appears. See also table 10, “Flue gas test”, page 34.

▶ After the “Burner” LED [6] has lit up wait for one minute until the

boiler is burning at full load.

▶ Use a foaming product to check all sealing locations in the total gas

circuit of the burner while the burner is active.

▶ Press the “Chimney sweep” button [3] to clear the reading. See also

table 10, “Flue gas test”, page 34.

Fig. 90 BC10 basic controller

DANGER: Danger of fatal accident from explosive

fumes.

▶ Check the testing nipples used for gas tightness.

▶ Only use approved leak detection products to locate

leaks.

WARNING:

Damage to the installation due to short circuits.

▶ Cover any hazardous locations prior to locating the

leaks.

▶ Do not spray the leak detection product on cable

runs, plugs or electrical wiring. Do not let it drip onto

them either.

DANGER: Danger of fatal accident from explosive

fumes.

Pipes and fittings may leak after commissioning

activities have been carried out.

▶ Only use approved leak detection products to locate

leaks.

WARNING:

Damage to the installation due to short circuits.

▶ Cover any hazardous locations prior to locating the

leaks.

▶ Do not spray the leak detection product on cable

runs, plugs or electrical wiring. Do not let it drip onto

them either.

Loading...

Loading...