Commissioning

6720813171 (2015/04) 37

10 Commissioning

This section explains how to start up the boiler.

▶ Complete the commissioning record log book after carrying out the

activities described below ( section 10.5 “Commissioning record

log book”, page 45).

10.1 Filling the heating system

10.1.1 Filling the heating system

The pre-pressure of the expansion vessel must be at least equal to the

static pressure (system height to the centre of the expansion vessel),

however never less than 0.5 bar.

▶ Push on the control panel to open it ( fig. 68).

▶ Turn the maximum CH flow temperature dial [8] and DHW

temperature dial [10] anticlockwise to the “0” position.

Fig. 70 BC10 basic controller

▶ Turn the vent key through a quarter rotation [1] to undo the boiler

door lock ( detailed picture).

▶ Push the fastener down [2] and open the boiler door [3].

▶ Remove the insulation cover of the pump group [4].

Fig. 71 Opening the boiler door

The boiler has an automatic air vent to purge the boiler.

To purge the boiler, every radiator in the heating system must have a

purge facility. In some situations it may even be necessary to provide

extra purging facilities at certain locations.

▶ Turn the cap of the automatic air vent through one rotation to loosen

it.

Fig. 72 Opening the automatic air purging unit

Filling and refilling of the heating circuit must have been carried out by a

method that has been approved by the Water Regulation Advisory

Scheme (WRAS), for the type of heating appliances, i.e. Domestic

(in-house) Fluid Category 3. Non-Domestic (other than in-house) Fluid

Category 4. Depending on the Fluid Category the approved method

should comprise of the following:

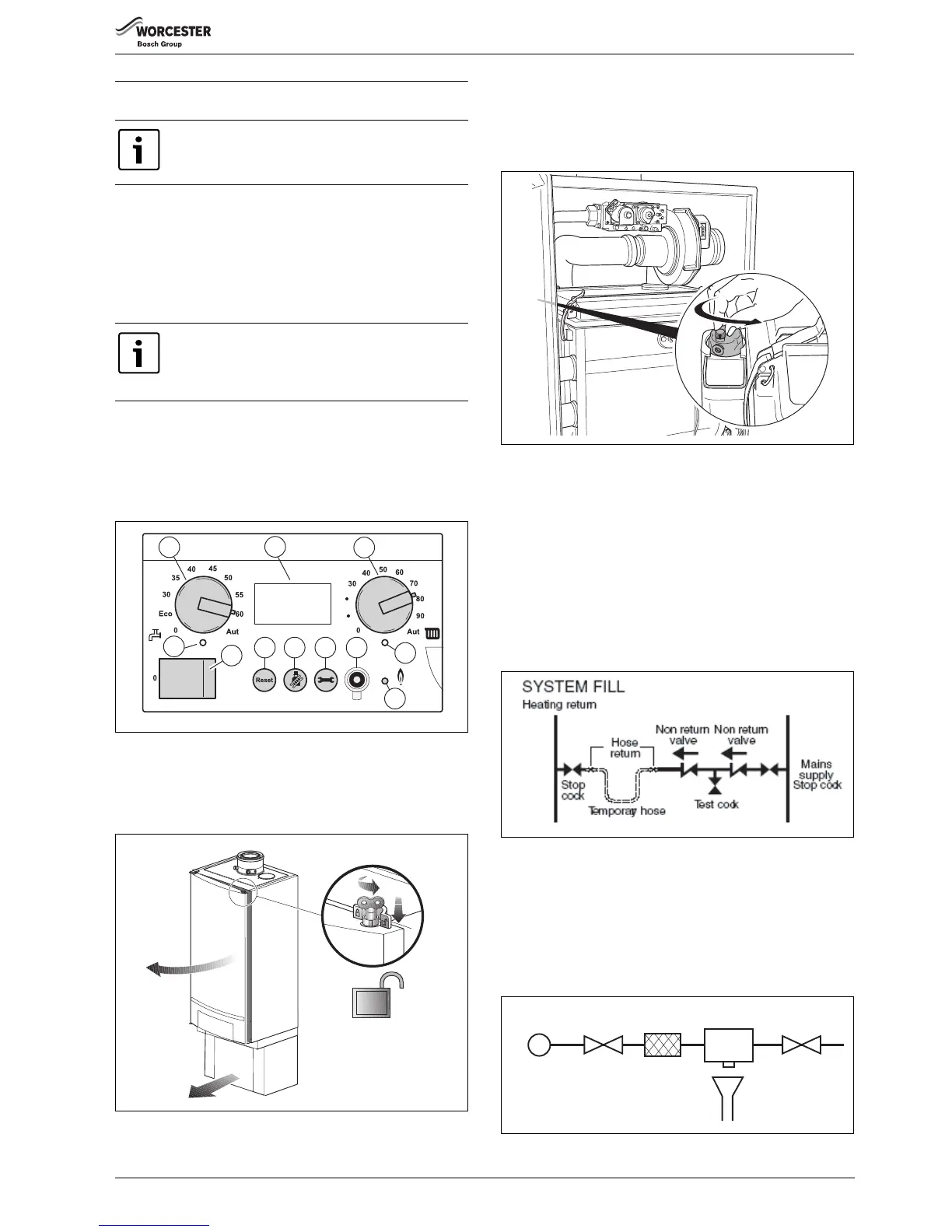

Requirements Fluid Category 3 systems

• Control valve (stop valve) including a double check valve on the

mains cold water supply pipe.

• Temporary connection to be removed after filling (filling loop).

• Control valve (stop valve) on the heating system pipework.

Fig. 73 System fill - category 3

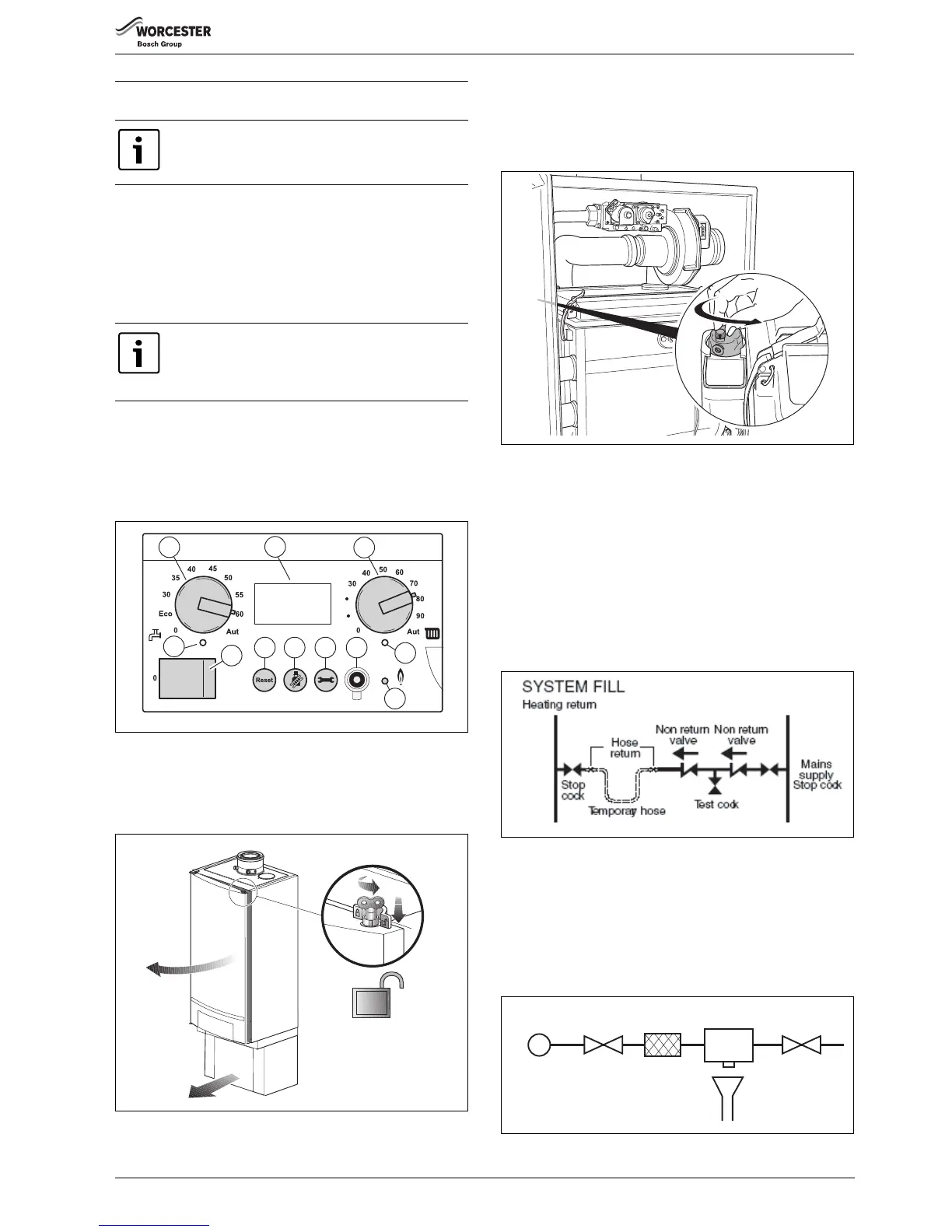

Requirements Fluid Category 4 systems

• Control valve (stop valve) on the mains cold water supply pipe.

•Strainer.

• Water non-return valve with reduced pressure Zone (RPZ valve

assembly) incorporating a Type BA air gap.

•Tundish.

• Control valve (stop valve) on the heating system pipework.

Fig. 74 System fill - category 4

If a fault occurs, then refer to the servicing manual or

contact Worcester.

At initial start up, the boiler will start up as soon as the

system pressure exceeds 1.0 bar. If the system pressure

falls to below 0.2 bar the boiler will stop and generate a

fault code.

Loading...

Loading...