Commissioning

6720813171 (2015/04) 39

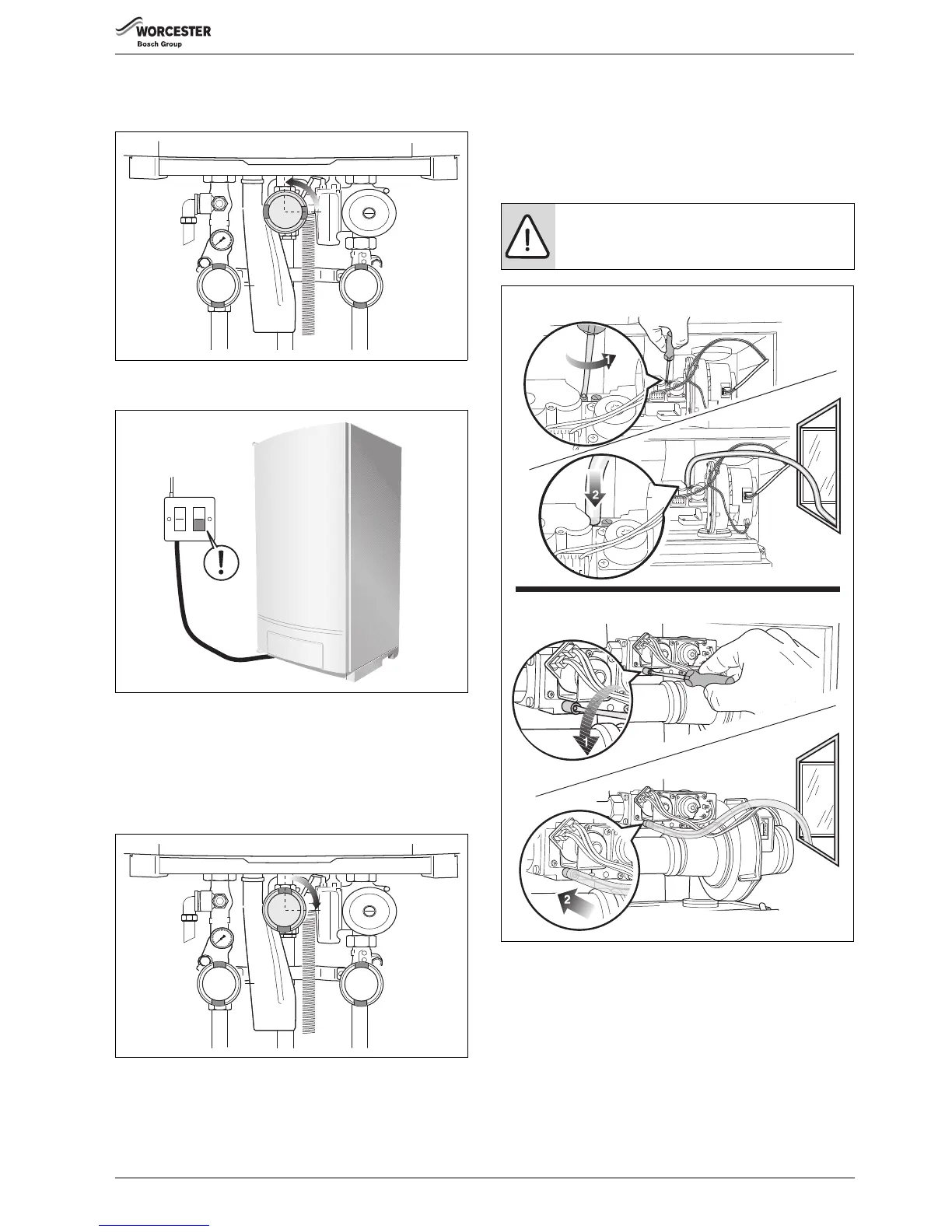

▶ Slowly open the gas valve by pushing on the gas valve and turning it

¼ rotation in an anticlockwise direction. The gas valve is open when

it is in the vertical position.

Fig. 79 Open the gas valve

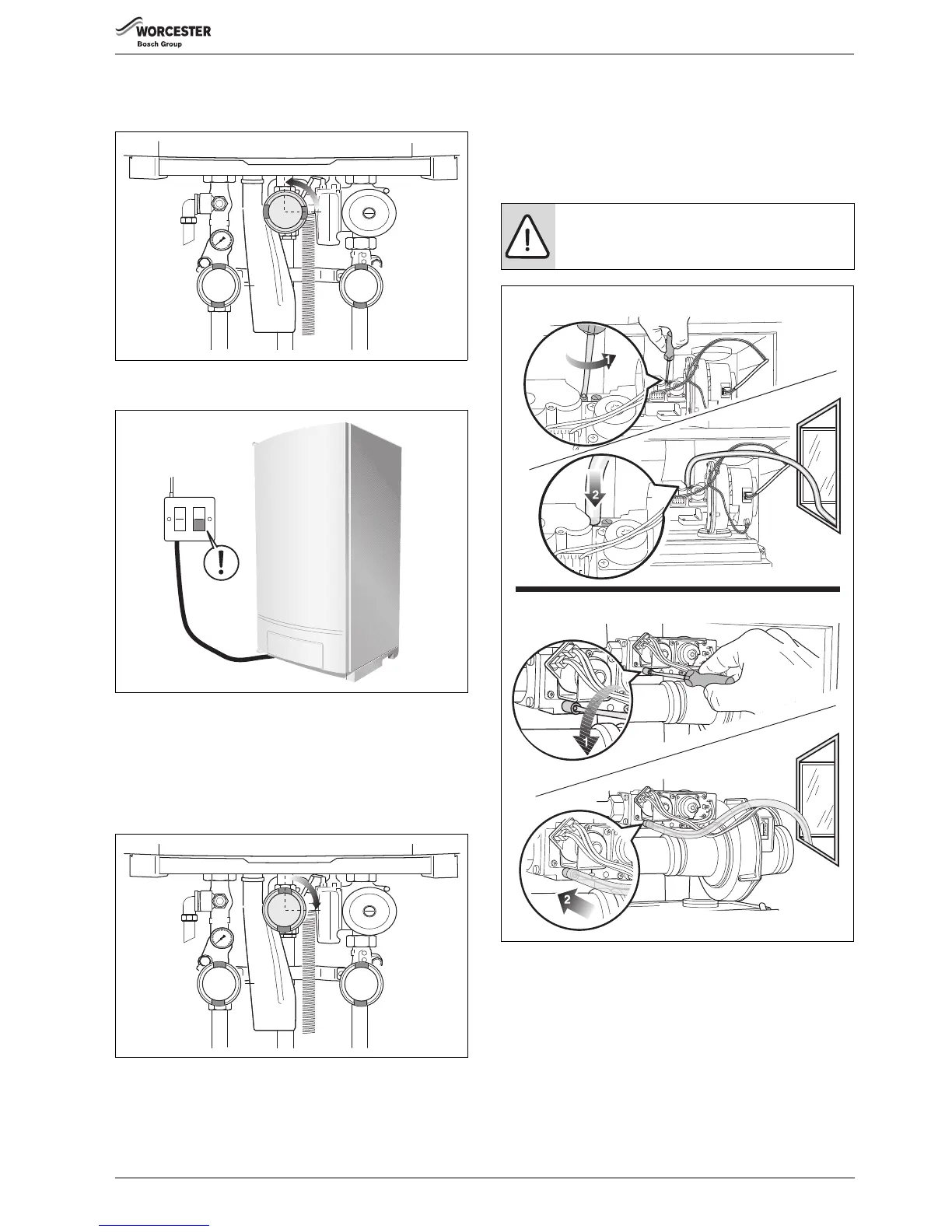

▶ Switch off the power supply to the heating system.

Fig. 80 Switch off the power supply to the heating system

▶ Check the new pipe section up to and including its connection (i.e.

direct sealing location) to the gas fitting for leaks, using a foaming

product. The maximum test pressure allowed at the gas valve inlet is

150 mbar.

10.2.2 Bleeding the gas flow pipe

▶ Close the gas valve.

Fig. 81 Closing the gas valve

▶ Open the screw plug on the testing nipple of the gas supply pressure

and for purging [1] by 2 turns and install a hose.

▶ Slowly open the gas valve by pushing on the gas valve and turning it

anticlockwise through ¼ rotation ( fig. 85, page 58). The gas valve

is open when it is in the vertical position.

▶ Purge the gas supply into a well ventilated area.

▶ Close the gas shut-off valve when no more air is present (fig. 87).

▶ Remove the hose and tighten the screw plug on the testing nipple

again.

Fig. 82 Bleeding the gas flow pipe

10.2.3 Gas consumption test

▶ Isolate all other appliances.

▶ Set the boiler to full load.

▶ Ensure that there is no modulating of the fan gas valve by operating

the test mode.

▶ Carry out the gas consumption procedure as described in the latest

edition of the Essential Gas Safety book.

Loading...

Loading...