STARTING THE APPLIANCE

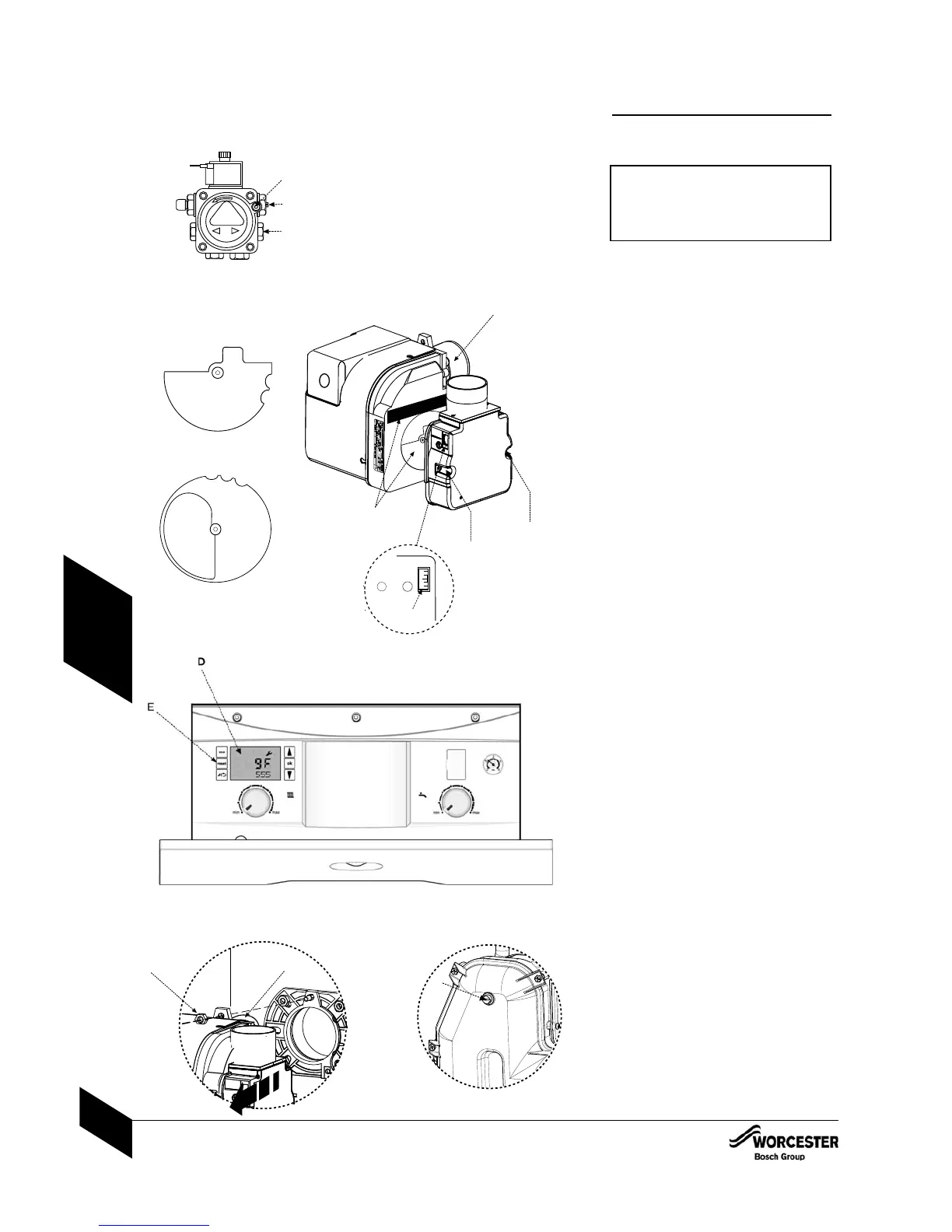

24 Fit a suitable pressure gauge to port (A) on

the oil pump.

IMPORTANT:

If changing the burner output, ensure the

position of the air damper disk is correct for

the desired output. Refer to the table on the

following page.

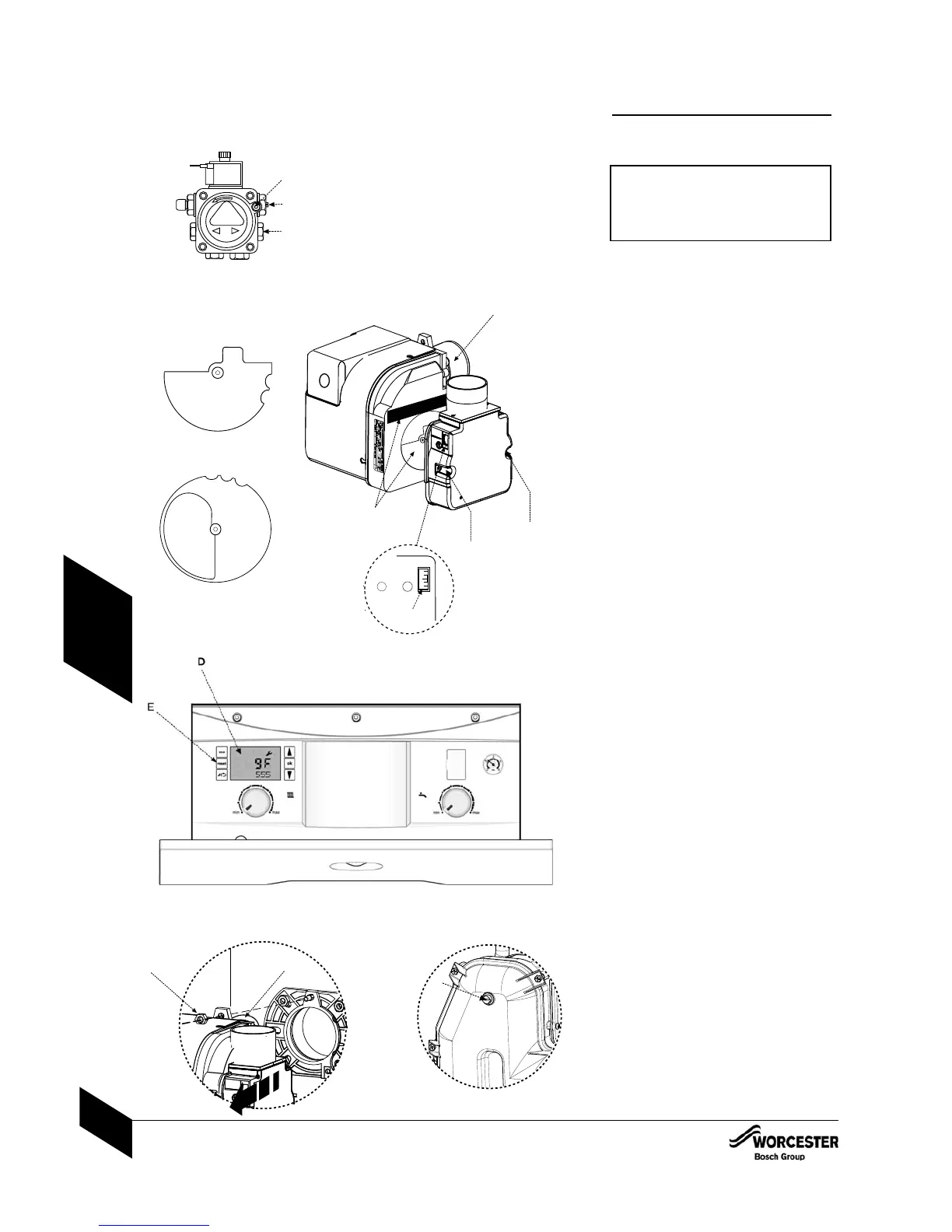

4 12/18 & 18/25 - RIELLO RDB 2.2

Adjust position of the air damper disc to suit

the burner output (see chart on page 44),

located as shown in the diagram opposite.

Access is by loosening the two star screws

(SC) to release the air inlet manifold.

• 25/32 - RIELLO RDB 2.2

No damper disk is fitted to the 25/32kW

burner.

4 Adjust the air shutter (L) and pump pressure

(B) as shown opposite. The burner should

ignite following a pre-ignition period of

approximately 15 seconds.

NOTE: The MO535 MRF control box has an

3.5 second delay before the start of

the pre-ignition.

Boiler lockout:

If the burner fails to establish a normal firing

pattern or flame failure occurs the flame

monitoring photocell mounted in the burner

body will alert the burner control box to shut the

burner down and provide a safe lockout state

indicated on the control panel LCD display (D)

by code 9F 555.

4Wait two minutes then press the lockout

reset button (E) to initiate another start

sequence.

4Repeat procedure until a flame is established.

34Start and run for 3 minutes then switch off.

4Check for after-spurting from the nozzle,

indicated by oil saturation on the combustion

head (G).

If after-spurting occurs:

4Release the burner retainer nut (H).

4Remove the burner, combustion head (G).

and electrodes, hold the burner vertical

to unscrew the nozzle and fill the nozzle

holder with oil.

4Refit nozzle, electrodes, combustion

head (G) and the burner.

4Restart and run for 3 minute intervals until

after-spurting stops.

44Start and run for 20 minutes.

4Remove sampling point plug ( J ) to check

the smoke reading is between 0-1. If the

smoke level is above 1, check the combustion

settings are correct and the oil nozzle is in

good condition.

NOTE: Smoke readings may be inaccurate until

the smoke from burning organic binder in

the access door insulation has ceased.

STARTING THE APPLIANCE

INSTALLATION & SERVICING INSTRUCTIONS FOR GREENSTAR HEATSLAVE II EXTERNAL 12/18-18/25-25/32

6 720 805 210-01

38

COMMISSIONING

Loading...

Loading...