6

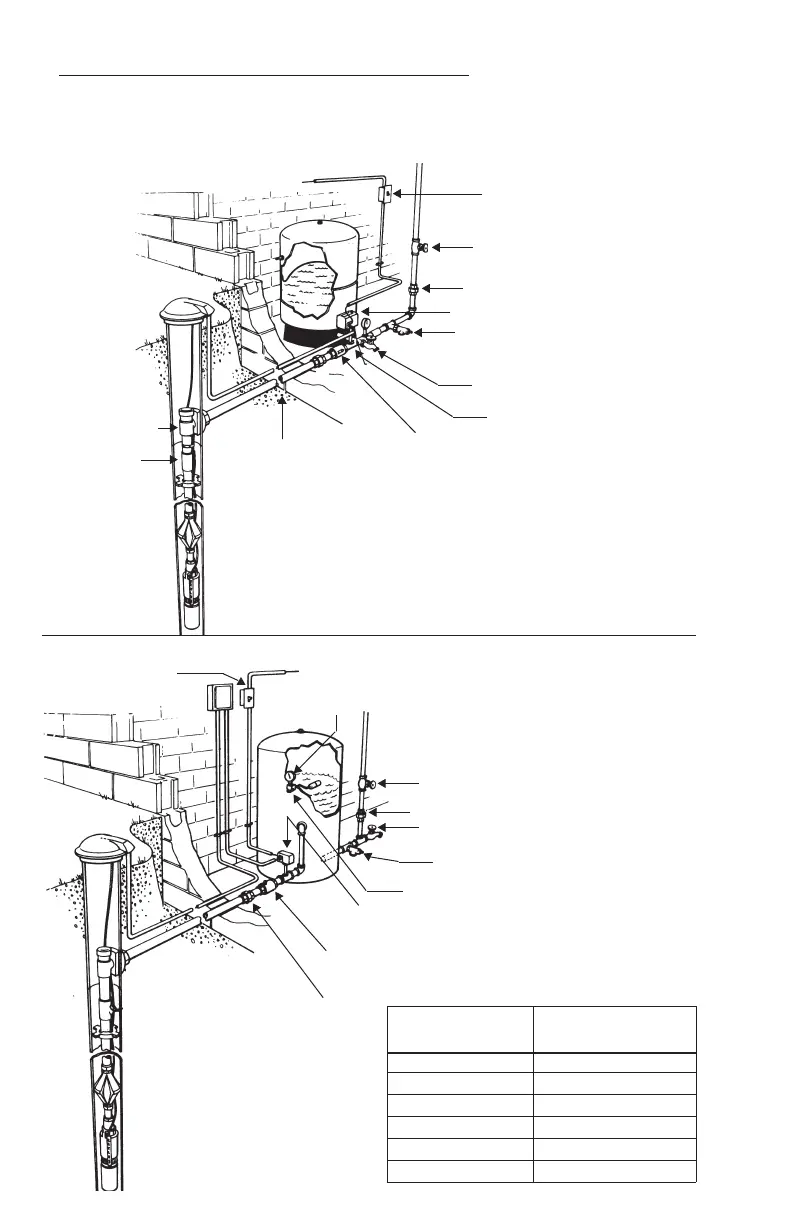

Figure 1

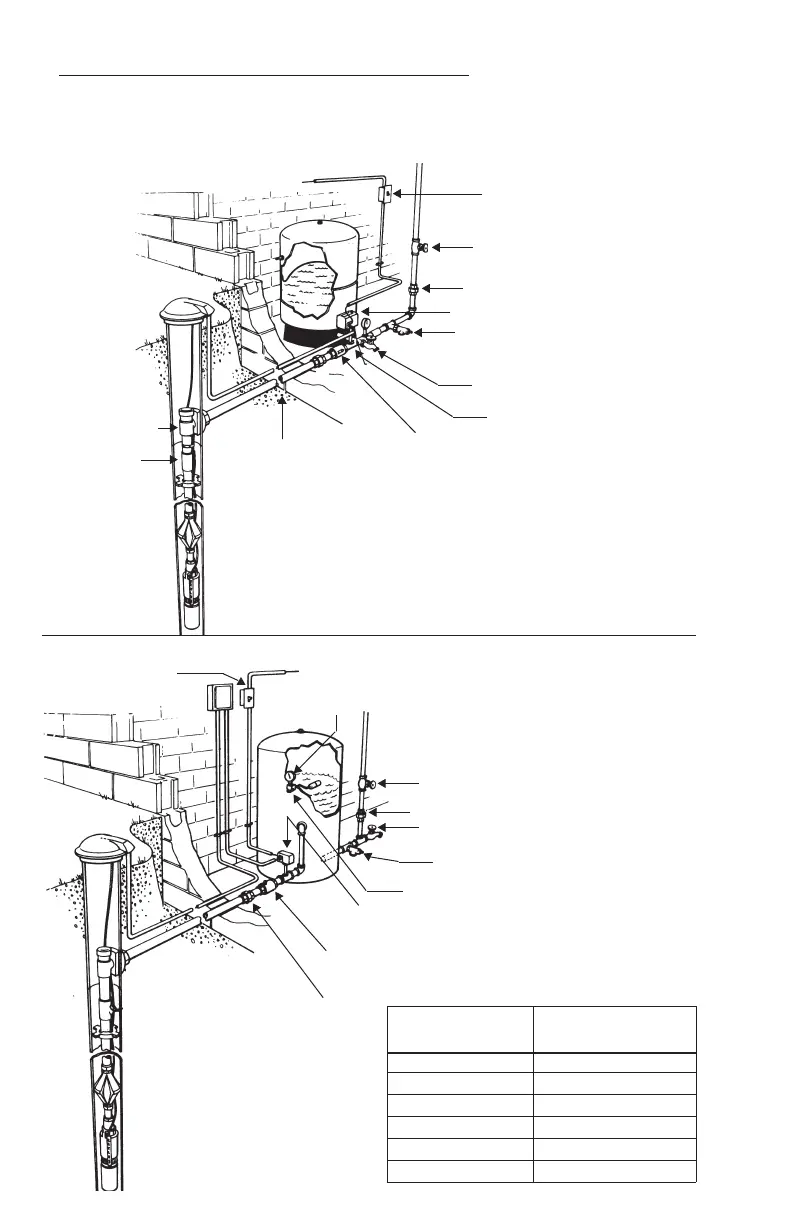

Figure 2

Protected Power Supply

Disconnect Switch

Control Box

Pressure

Gauge

To House

Piping

Shut-off Valve

Union

Drain Tap

Pressure Relief Valve

Air Escape Control

Pressure Switch

Line Check Valve with Snifter

Union

Pitless Adapter

Drain and Y Fitting

Approximate Drain Fitting Setting

Distance Drain and “Y”

Tank Capacity Fitting Below the Line Check

42 gallon (159 L) 7 feet (2.1m)

82 gallon (310 L) 10 feet (3m)

120 gallon (454 L) 15 feet (4.6m)

220 gallon (833 L) 15 feet (4.6m)

315 gallon (1192 L) 20 feet (6.1m)

525 gallon (1981 L) 20 feet (6.1m)

Protected Power Supply

To House Piping

Disconnect Switch

Shut-off Valve

Union

Pressure Relief Valve

Drain Tap

Tank Tee

Check Valve ②

Frost Level

GALVANIZED TANK INSTALLATION

1.0 TYPICAL INSTALLATIONS

Check Valve ①

Pitless Adapter ①

Pressure Switch

① On installations with a pitless adapter the top check

valve should be below the pitless, not at the tank, as the

discharge line should be pressurized back to the pitless.

② On installations with well seals or well pits it is allowable

to locate the top check valve near the tank.

CAPTIVE AIR TANK INSTALLATION

NOTICE: TANK PRE-CHARGE PRESSURE CHANGES MUST BE

MADE USING THE AIR VALVE ON TOP OF THE TANK.

Loading...

Loading...