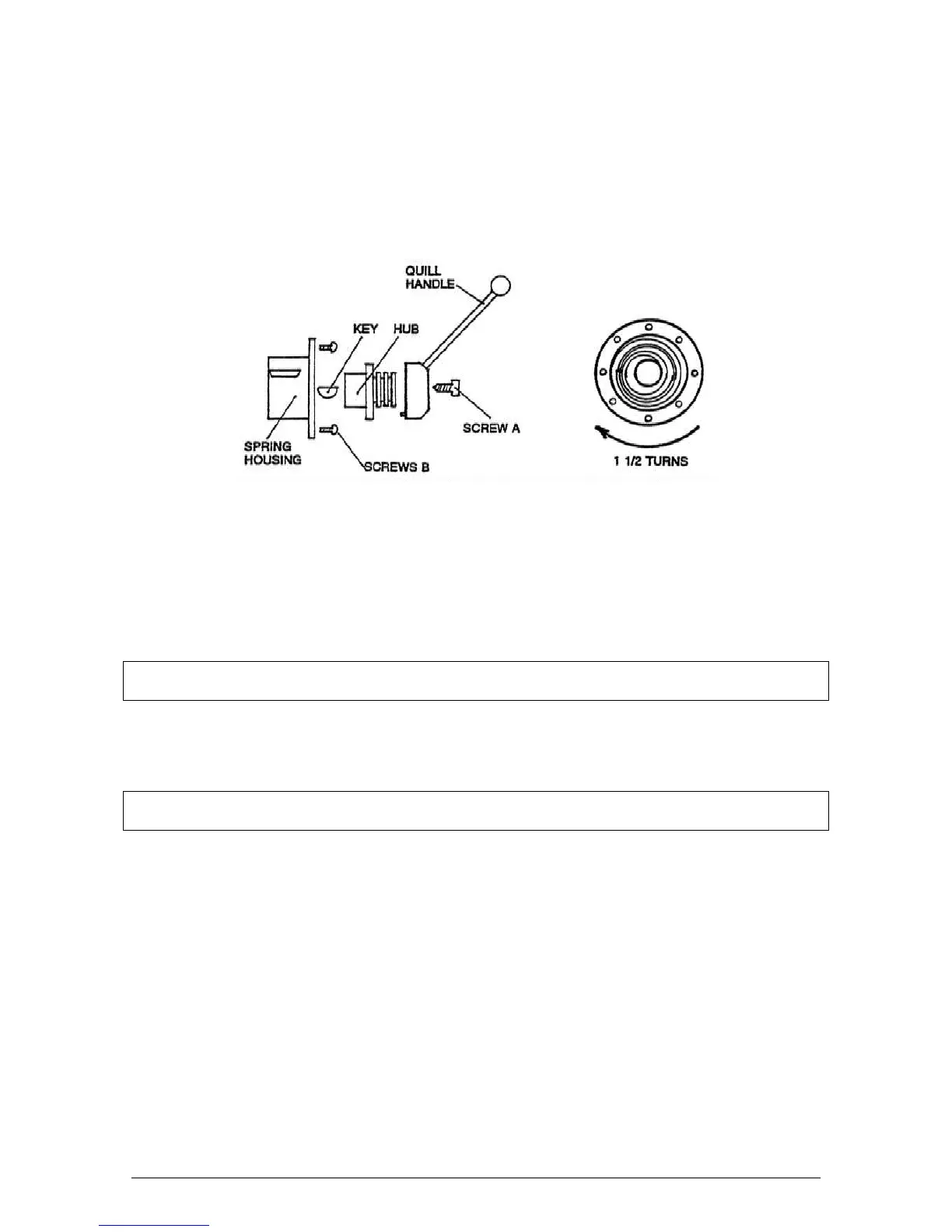

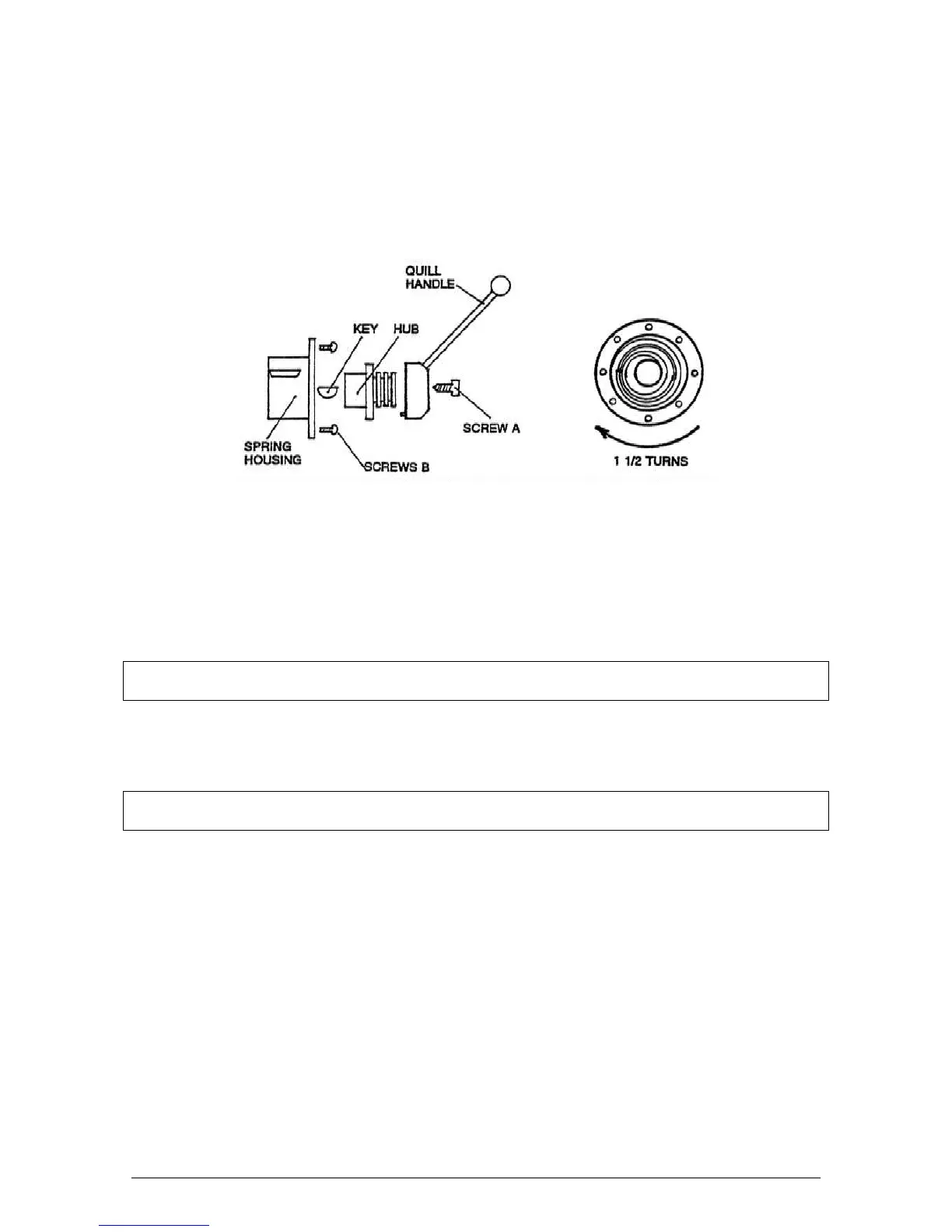

To adjust:

1. Move the quill to its top position and lock it in place.

2. Remove the quill handle, hub (by removing Screw A) and key.

3. Remove Screws B and allow the spring housing to unwind.

4. Remove the spring. It is held by a pin on the shaft and slot in the housing.

5. Replace the spring. Rotate the housing clockwise until the spring catches the shaft pin.

6. Rotate (wind up) the housing 1 1/2 turns, replace Screws B, key hub, Screw A, and handle.

Figure 32 - Quill Clock Spring Replacement

5.1.12 Spindle Motor Removal and Replacement – 3500, 4000 & 5000

1. Isolate and lock out power to the machine.

2. Disconnect the electrical connections in the conduit box attached to the motor.

3. Remove the three bolts that hold the motor pulley cover in place to gain access to the belt.

4. Remove the four bolts that mount the motor to the top head housing and slide motor forward and

remove belt.

CAUTION!

The motor is heavy--about 40kg. Use handling equipment or seek assistance.

5. Tilt the motor towards the back and remove the belt from the motor pulley. Remove the motor.

6. To reinstall motor, do these steps in reverse.

5.1.13 Spindle Motor Removal and Replacement - 2500

CAUTION!

The motor is heavy--about 30kg. Use handling equipment or seek assistance.

1. While the spindle is running, change the RPM to its lowest value.

2. Turn off spindle.

3. Isolate and lock out power to the machine.

4. Remove motor pulley cover.

5. Screw a 4 x 20 mm SHCS into the bottom of the adjustable vari-disk to keep the vari-disk open.

6. Crank the speed changer to its highest RPM value. This will allow the main drive belt enough slack

to slide off the motor pulley.

7. Remove the four SHCS that fasten the motor to the belt housing.

8. Tilt the motor toward the rear of the machine, and remove the belt from the motor pulley.

Remove the motor.

9. To reinstall motor, do these steps in reverse.

Loading...

Loading...