To adjust the gib for excessive clearance: Loosen the gib lock screw on the back of

the saddle. Estimate the amount of gib lock screw adjustment required, and tighten the

gib lock screw on the front of the saddle. Tighten the gib lock screw on the back end of

the saddle to lock the gib in place, and recheck. Repeat as necessary.

To adjust the gib for too small of a clearance: Loosen the gib lock screw on the

front of the saddle. Estimate the amount of gib lock screw adjustment required and

tighten the gib lock screw on the back of the saddle. Tighten the gib lock screw on the

front of the saddle to lock the gib in place, and recheck. Repeat as necessary.

5.2.1.6

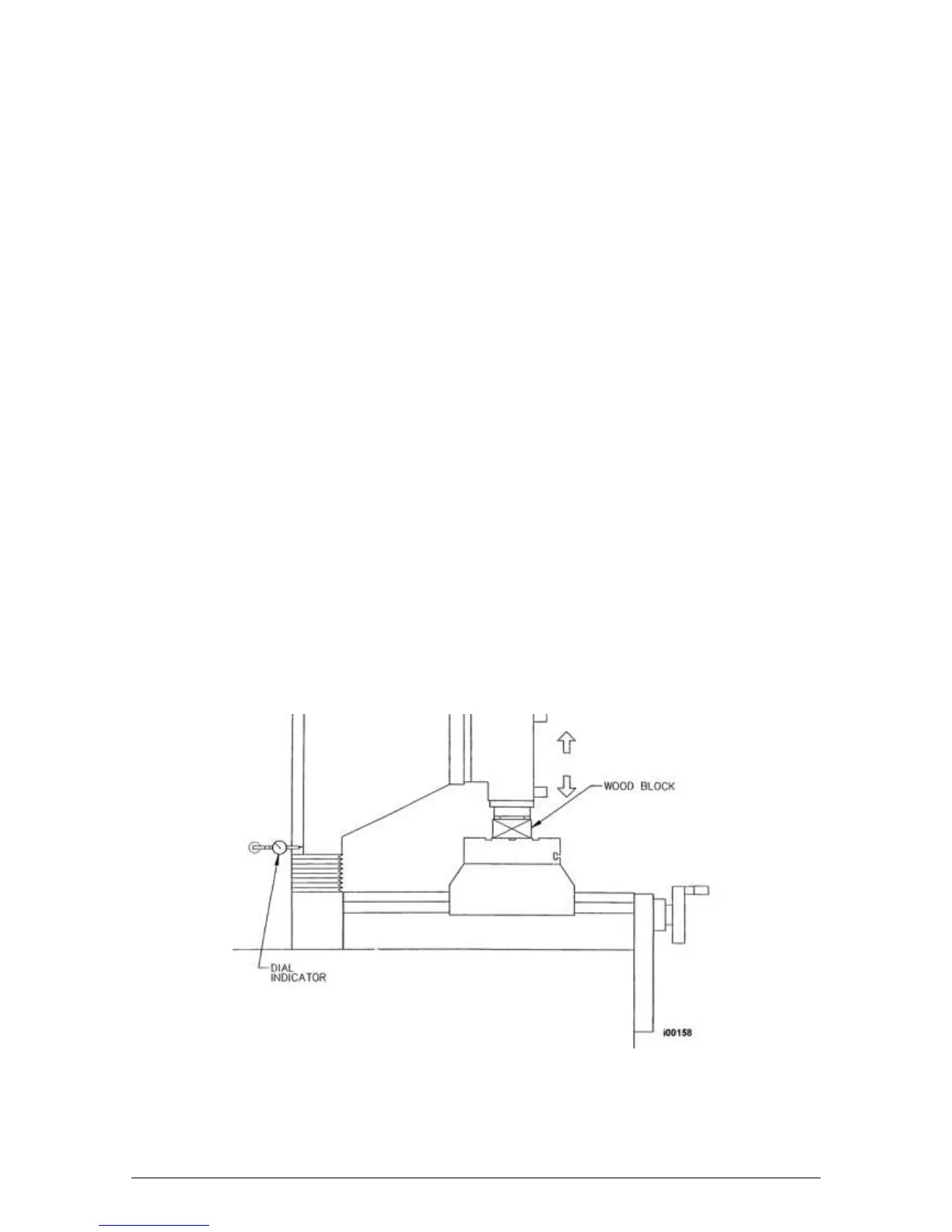

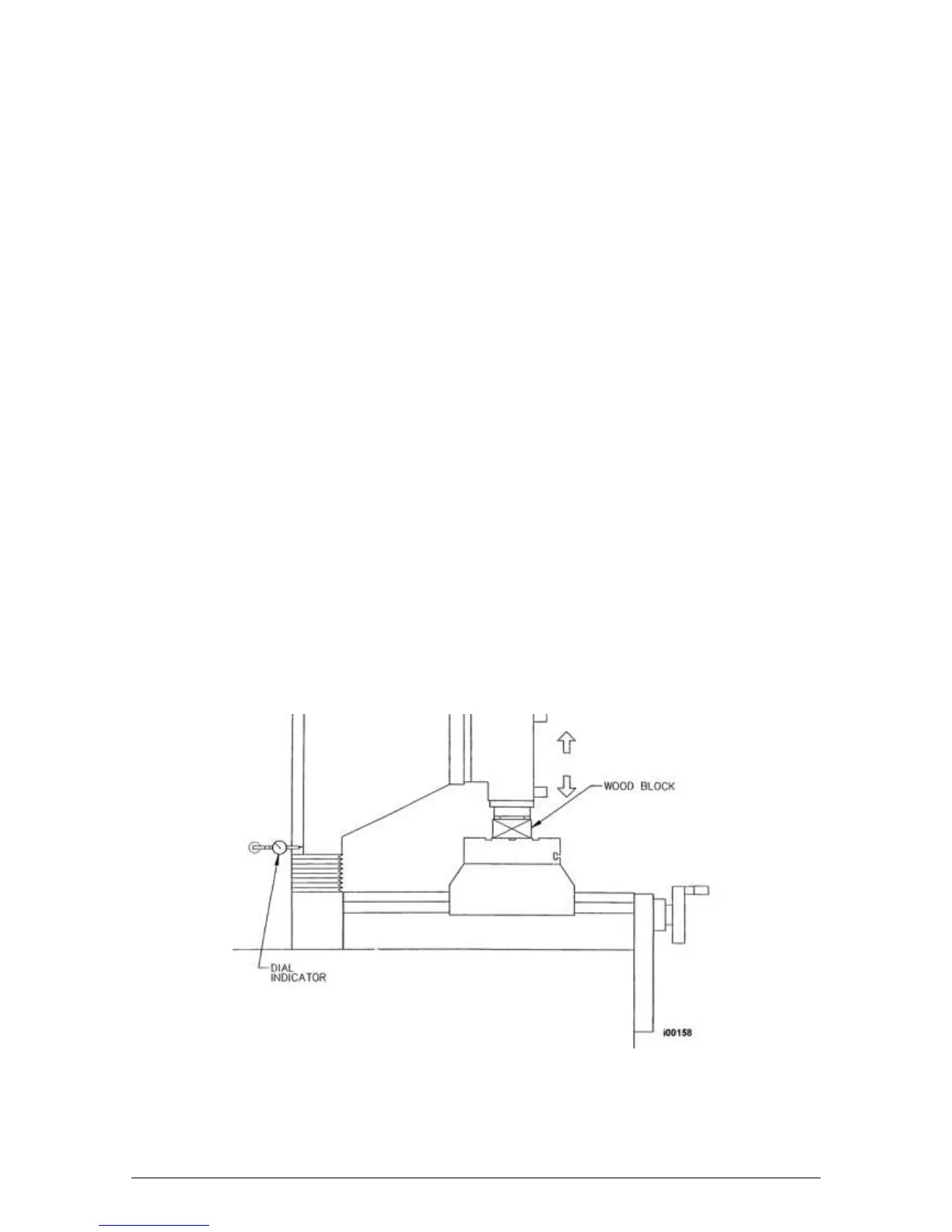

Head Back Gib Adjustment - Z Axis

1. Clean all swarf, dirt and excess oil from the table and saddle.

2. Disconnect one end of the upper and lower way cover where it is attached to the ram.

3. Position the milling head such that the table can be reached by extending the quill

approximately 3/4 of its travel.

4. Place a wood block on the table underneath the spindle.

5. Attach a dial indicator with a magnetic base to the column near the base of the ram on the

left side of the machine. Place the indicator stylus on the rear surface of the ram near the

bottom.

6. Extend the quill until it touches the wood block. Using the quill handle, push the spindle nose

against the wood block and note the amount of movement on the dial indicator. Adjust the

left side gib until the registered movement is 0.02-0.01mm.

To adjust the gib for excessive clearance: Loosen the gib lock screw on the bottom

of the ram. Estimate the amount of gib lock screw adjustment required and tighten the

gib lock screw on the top of the ram. Tighten the gib lock screw on the bottom of the

ram to lock the gib in place, and recheck. Repeat as necessary.

To adjust the gib for too small of a clearance: Loosen the gib lock screw on the top

of the ram. Estimate the amount of gib lock screw adjustment required and tighten the

gib lock screw on the bottom of the ram. Tighten the gib lock screw on the bottom of the

ram. Tighten the gib lock screw on the top of the ram to lock the gib in place, and

recheck. Repeat as necessary.

7. Run Service Code 12 to set the feed forward constant.

8. Repeat the procedure for the back gib on the right side of the machine.

Figure 41 - Head Back Gib

Loading...

Loading...