CYLINDER AND PISTON

5-25

EAS24380

REMOVING THE PISTON

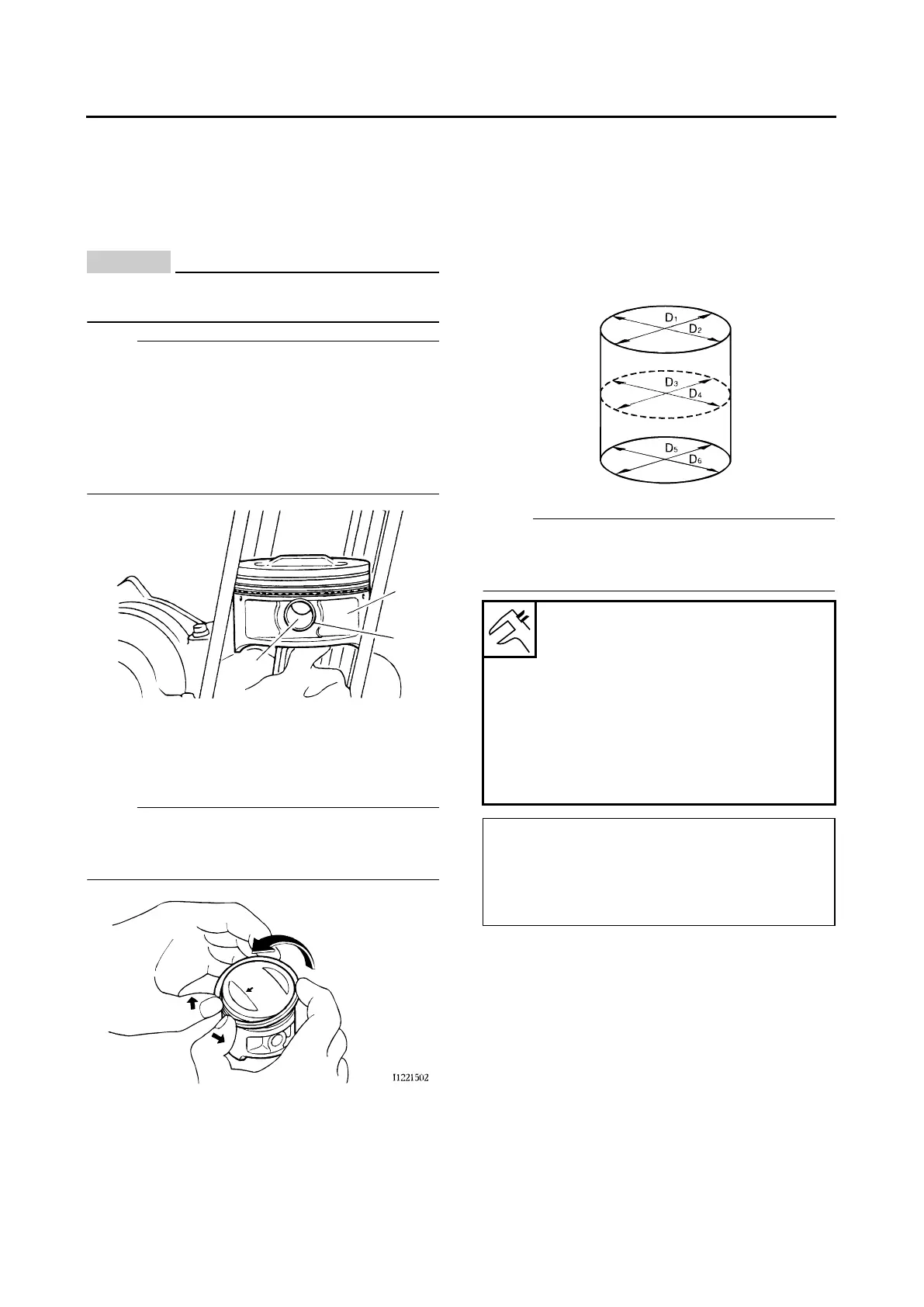

1. Remove:

● Piston pin clips “1”

● Piston pin “2”

● Piston “3”

CAUTION:

ECA13810

Do not use a hammer to drive the piston pin

out.

NOTE:

● Before removing the piston pin clip, cover the

crankcase opening with a clean rag to prevent

the piston pin clip from falling into the crank-

case.

● Before removing the piston pin, deburr the pis-

ton pin clip's groove and the piston's pin bore

area.

2. Remove:

● Top ring

● 2nd ring

● Oil ring

NOTE:

When removing a piston ring, open the end gap

with your fingers and lift the other side of the ring

over the piston crown.

EAS24400

CHECKING THE CYLINDER AND PISTON

1. Check:

● Piston wall

● Cylinder wall

Vertical scratches → Rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

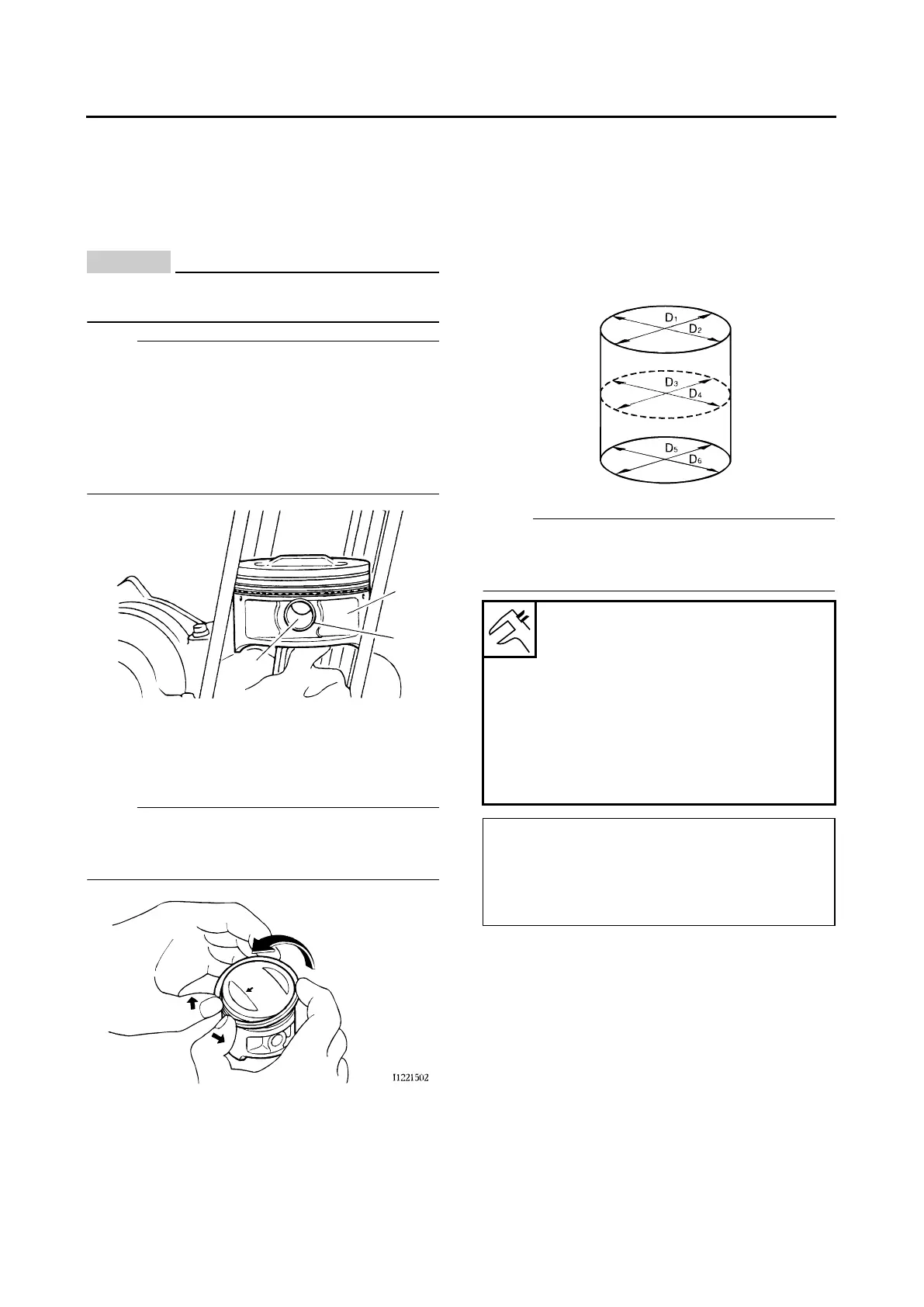

2. Measure:

● Piston-to-cylinder clearance

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Measure cylinder bore “C” with the cylinder

bore gauge.

NOTE:

Measure cylinder bore “C” by taking side-to-side

and front-to-back measurements of the cylinder.

Then, find the average of the measurements.

b. If out of specification, replace the cylinder,

and the piston and piston rings as a set.

c. Measure piston skirt diameter “D” with the mi-

crometer.

2

1

3

Cylinder bore “C” -

Bore

79.000–79.010 mm

(3.1102–3.1106 in)

Taper limit

0.05 mm (0.0020 in)

Out of round limit

0.100 mm (0.0039 in)

Warp limit

0.03 mm (0.0012 in)

“C”=maximum of D1–D6

“T”=maximum of D1 or D2—maximum of D5

or D6

“R”=maximum of D1, D3 or D5—minimum of

D2, D4 or D6

Loading...

Loading...