30

6. MAINTENANCE PROCEDURE

Inspection & Maintenance

Conduct daily general inspections and maintenance for optimal performance.

Warning

●

Turn off main power switch and disconnect power cable before daily inspection and maintenance.

●

Inspect and perform maintenance on unit when chamber is at room temperature.

●

Never disassemble equipment.

Caution

●

Clean unit exterior using soft damp cloth.

●

Never use benzene, paint thinner, scouring powder, scrubbing brush or other abrasives/solvents to

clean unit. Superficial damage and/or discoloration, as well as deformity to some components may

result.

Daily.

When processing biological media, clean chamber daily with a damp cloth.

Weekly.

Thorougly clean the inside of chamber with a clean damp cloth, weekly, regardless of processing item

type. Do not remove drain filter for cleaning, otherwise drain pipe may become clogged with debris.

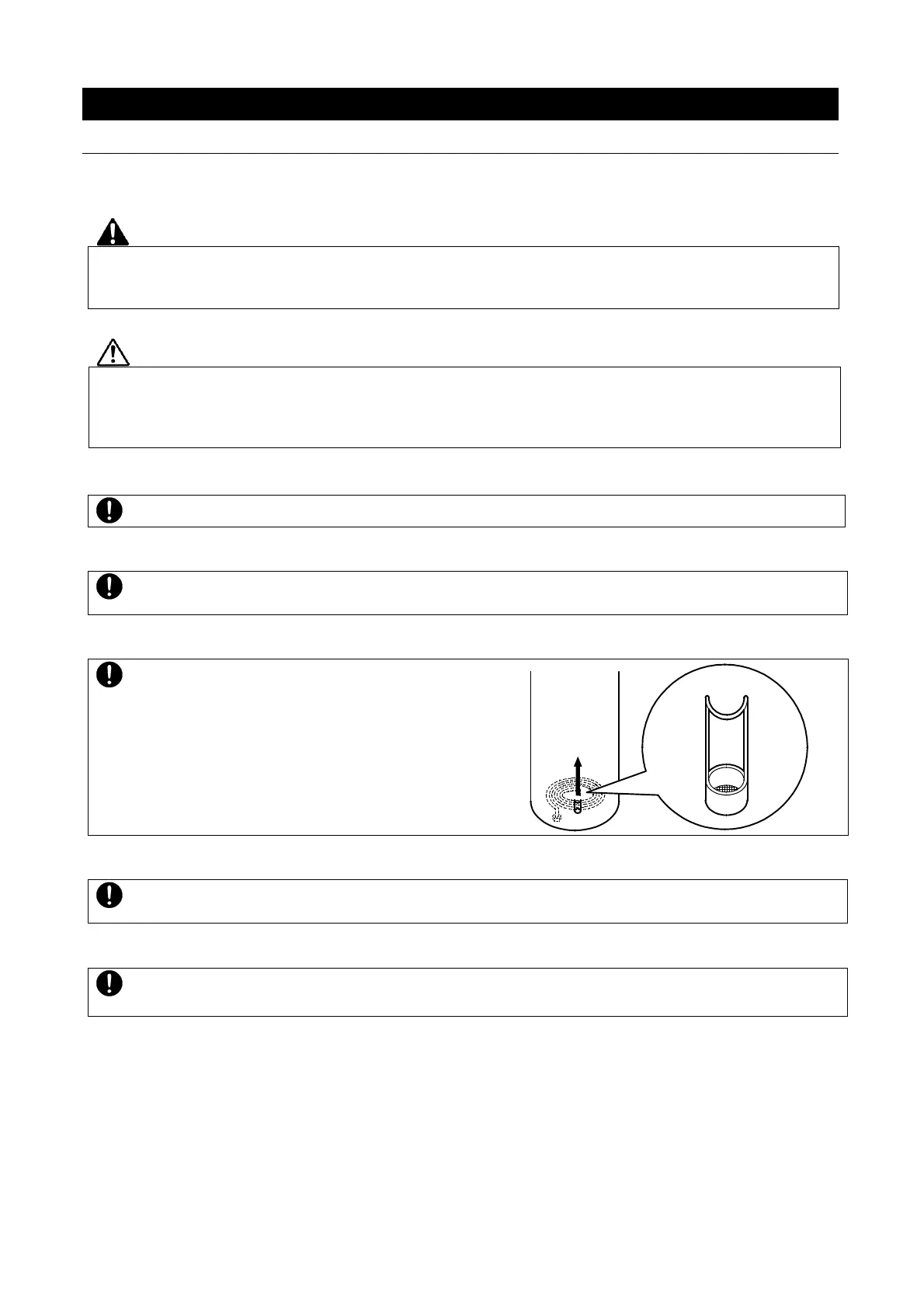

Clean Filter.

Draining may be hampered if filter is allowed to

become clogged. Clean filter at appropriate

intervals, according to frequency of use.

Remove filter from bottom drain port and clean

with tap water.

Lid seal cleaning & replacement.

The lid seal may be wiped clean with a clean damp cloth, and should be examined regularly for cracks

or damage. To replace, contact a local dealer Yamato sales office for assistance.

Cleaning coil heater.

The coil heater in the bottom of chamber should be cleaned twice a month.

Mineral deposit buildup on heater will result in poor heat transfer and will cause sheathing to overheat.

Loading...

Loading...