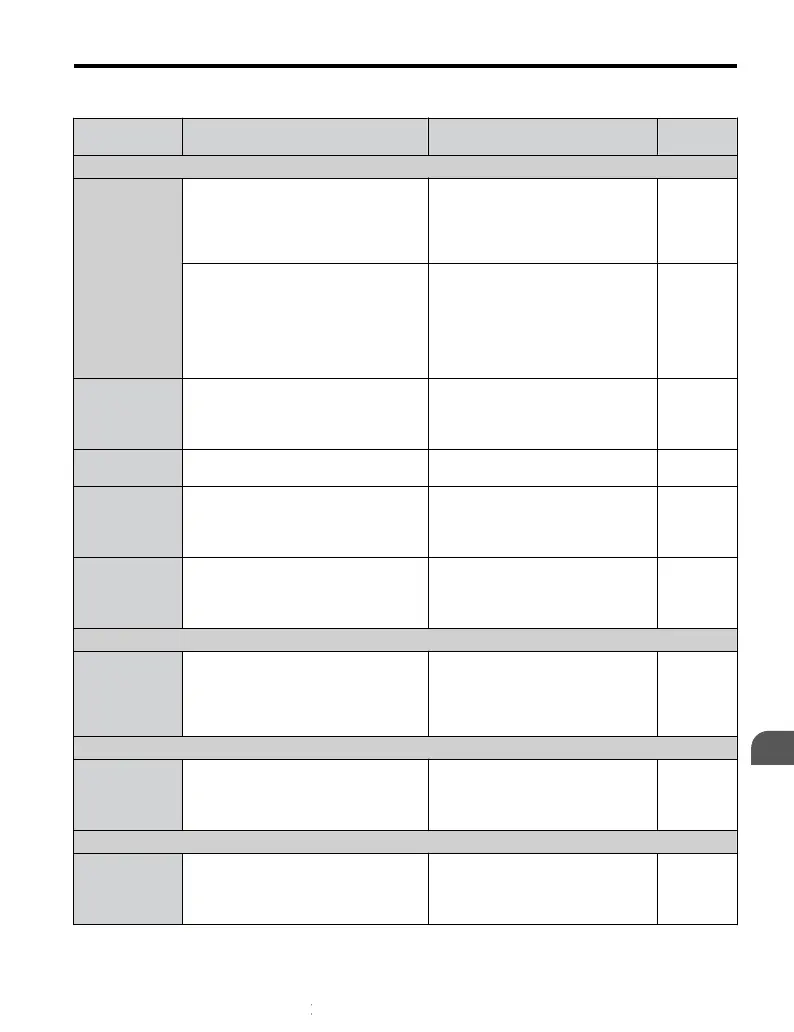

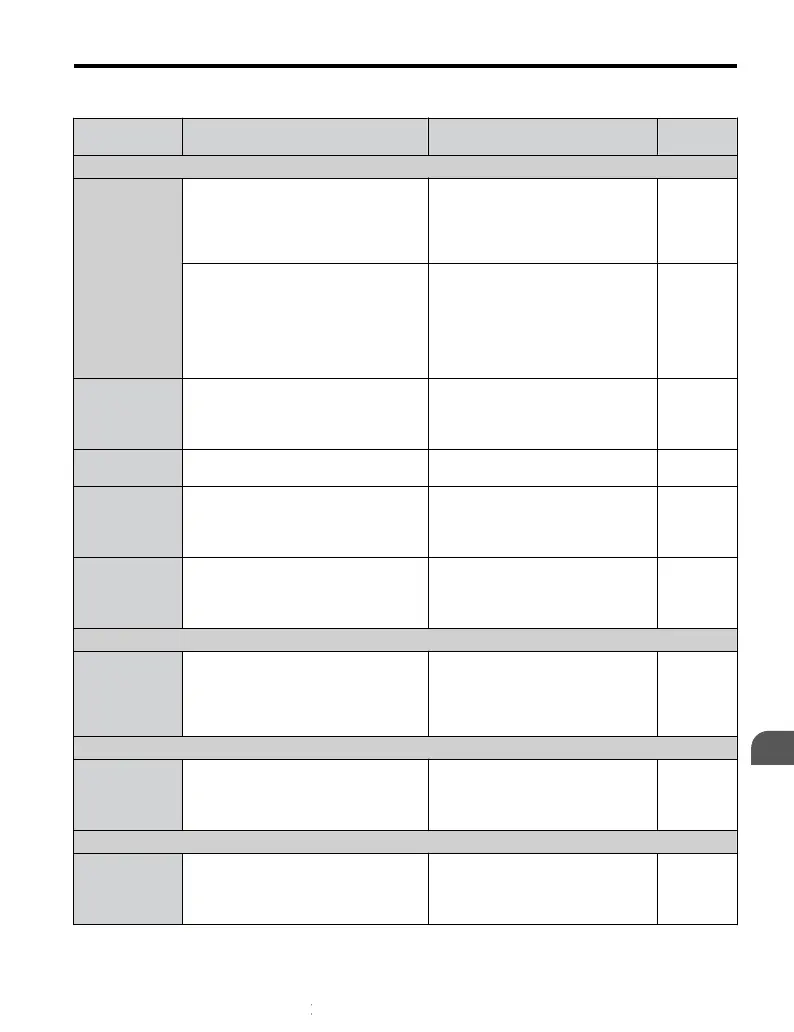

Table 6.2 Periodic Inspection Checklist

Inspection

Area

Inspection Points Corrective Action Checked

Main Circuit Periodic Inspection

General

• Inspect equipment for discoloration

from overheating or deterioration.

• Inspect

for

damaged or deformed parts.

• Replace damaged components as

required.

• The drive has few serviceable parts

and may require complete drive

replacement.

• Inspect for dirt, foreign particles, or dust

collection on components.

•

Inspect enclosure door seal if

present. Replace components if

cleaning is not possible.

• Use dry air to clear away foreign

matter. Use a pressure of:

39.2 x 10

4

to 58.8 x 10

4

Pa (4 - 6 kg

•cm

2

).

Conductors and

Wiring

• Inspect wiring and connections for

discoloration, damage, or heat stress.

• Inspect wire insulation and shielding

for wear.

•

Repair or replace damaged wiring.

Terminals

• Inspect terminals for stripped,

damaged, or loose connections.

• Tighten loose screws and replace

damaged screws or terminals.

Relays and

Contactors

• Inspect contactors and relays for

excessive noise during operation.

• Inspect coils for signs of overheating

such as melted or cracked insulation.

•

Check coil voltage for over or under

voltage conditions.

• Replace damaged removable relays

contactors or circuit board.

Braking

Resistors

• Inspect for discoloration of heat stress

on or around resistors.

• Minor discoloration may be

acceptable.

• If discoloration exists check for

loose connections.

Control Circuit Periodic Inspection

General

• Inspect terminals for stripped, damaged

or loose connections.

•

Check for tightness.

• Tighten loose screws and replace

damaged screws or terminals.

• If terminals are integral to a circuit

board then board or drive

replacement may be required.

LED Periodic Inspection

LEDs

• Make sure the LED lights correctly.

• Inspect for dust or other foreign

material that may have collected on

surrounding components.

•

Contact your Yaskawa

representative if there is any trouble

with the LED or keypad.

• Clean the LED.

Cooling System Periodic Inspection

Cooling Fan

• Check for abnormal oscillation or

unusual noise.

• Check for damaged or missing fan

blades.

•

Replace as required.

• Refer to Drive Cooling Fans on

page 170 for information on

cleaning or replacing the cooling fan.

6.2 Inspection

YASKAWA ELECTRIC TOEP C710606 26B YASKAWA AC Drive – J1000 Quick Start Guide

165

6

Periodic Inspection &

Maintenance

Loading...

Loading...