Parameter Details

2

2.4 C: Tuning

YASKAWA TOEPYAIGA5002A GA500 DRIVE PROGRAMMING 213

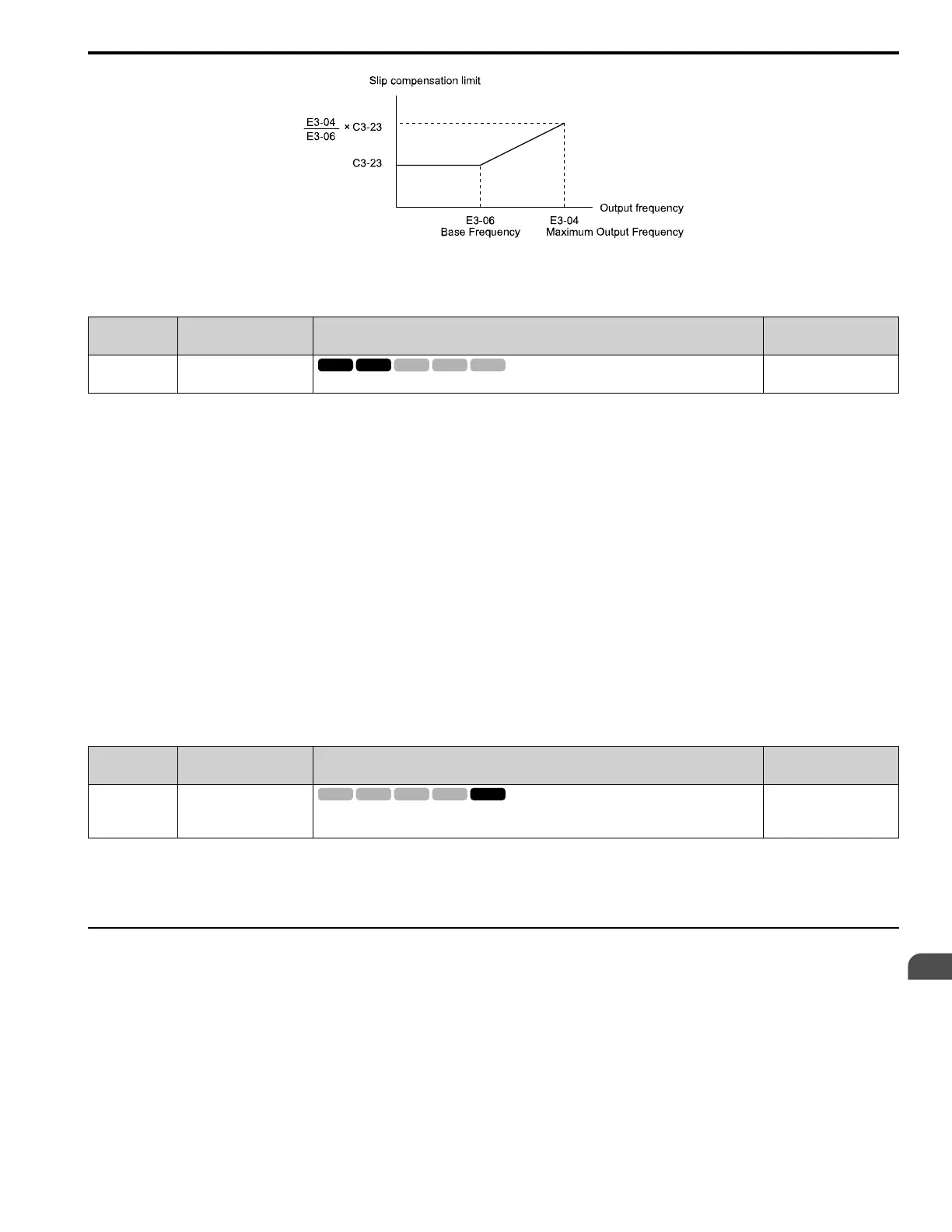

Figure 2.36 Motor 2 Slip Compensation Limit

■ C3-24: Motor 2 Slip Comp during Regen

No.

(Hex.)

Name Description

Default

(Range)

C3-24

(0243)

Motor 2 Slip Comp during

Regen

Sets the slip compensation during regenerative operation function for motor 2.

0

(0 - 2)

If you apply a regenerative load when the slip compensation function during regeneration is active, the quantity of

regeneration can increase immediately. In this condition, it is necessary to use a dynamic braking option (braking

resistor or braking resistor unit).

0 : Disabled

The drive will not do Slip compensation during regeneration.

The load and operation status (regenerative operation) can cause the motor speed to be higher or lower than the

frequency reference.

1 : Enabled Above 6Hz

Slip compensation function is enabled during regeneration. Slip compensation is disabled at output frequencies of 6

Hz or less.

2 : Enabled Above Defined Range

The drive uses E2-02 [Motor Rated Slip] to automatically calculate the frequency range where it will disable slip

compensation function during regenerative operation.

Slip compensation is enabled at frequencies as low as 2 Hz.

■ C3-29: Slip Compensation Gain @ Low Spd

No.

(Hex.)

Name Description

Default

(Range)

C3-29

(1B5D)

Expert

Slip Compensation Gain @

Low Spd

Sets the gain for the slip compensation function in the low speed range. Usually it is not necessary to

change this setting.

0.0

(0.0 - 2.5)

Adjust this parameter as follows if necessary:

• If the motor speed is slower than the frequency reference, increase the setting value in 0.1 unit increments.

• If the motor speed is faster than the frequency reference, decrease the setting value in 0.1 unit increments.

◆ C4: Torque Compensation

Torque compensation is a function that increases voltage to increase output torque as compensation for insufficient

torque production at start-up or low-speed operation.

Voltage drops due to motor winding resistance cause torque generating voltage to decrease, which causes insufficient

torque. If the main circuit cable connecting the drive and motor is long, this can also cause insufficient torque due to

voltage drops.

Note:

Set the motor parameters and V/f pattern properly before setting C4 parameters.

Loading...

Loading...