2.9 L: Protection Functions

394 YASKAWA TOEPYAIGA5002A GA500 DRIVE PROGRAMMING

6 : UL5 @ |Speed| < L6-09 - Alarm

When the speed (absolute value) ≤ L6-09, the drive detects mechanical weakening. The drive will detect UL5 and

continue operation.

7 : UL5 @ Speed < L6-09 - Fault

When the speed (signed) ≤ L6-09, the drive detects mechanical weakening. The drive will detect UL5 and stop

operation.

8 : UL5 @ |Speed| < L6-09 - Fault

When the speed (absolute value) ≤ L6-09, the drive detects mechanical weakening. The drive will detect UL5 and stop

operation.

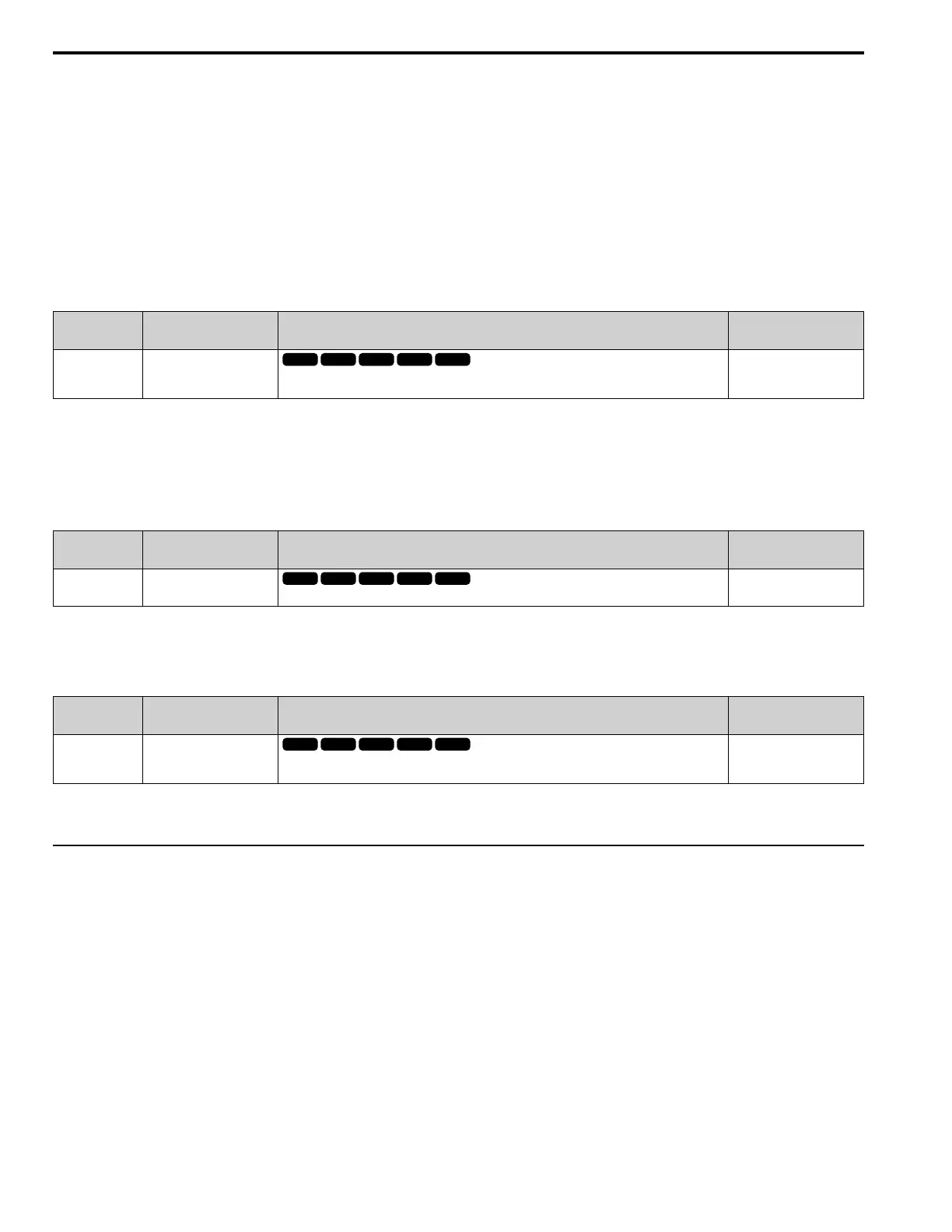

■ L6-09: Mech Fatigue Detect Speed Level

No.

(Hex.)

Name Description

Default

(Range)

L6-09

(0469)

Mech Fatigue Detect Speed

Level

Sets the speed level where the drive will operate the mechanical deterioration detection function, as a

percentage of the Maximum Output Frequency.

110.0%

(-110.0 - 110.0%)

Parameters L6-01 to L6-03 [Torque Detection 1 Settings Parameters] set the overtorque/undertorque detection

conditions.

When L6-08 = 2, 4, 6, 8 [Mechanical Fatigue Detect Select = Speed : unsigned], the setting value of L6-09 is the

absolute value. When L6-09 is set to a negative number, the drive processes this value as a positive number.

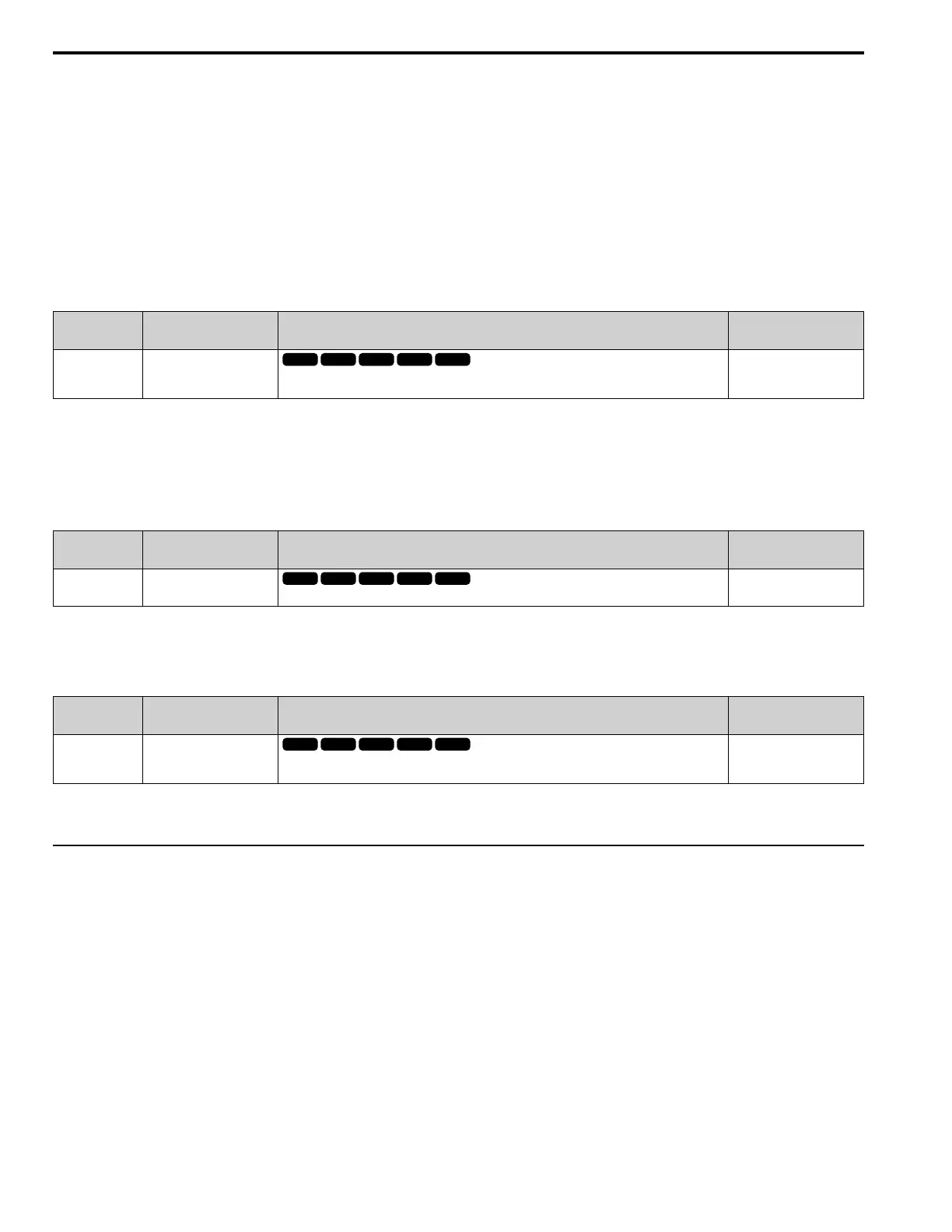

■ L6-10: Mech Fatigue Detect Delay Time

No.

(Hex.)

Name Description

Default

(Range)

L6-10

(046A)

Mech Fatigue Detect Delay

Time

Sets the time for mechanical deterioration detection.

0.1 s

(0.0 - 10.0 s)

When the detection conditions set in L6-08 [Mechanical Weakening Detect Ope] continue for the time set in L6-10,

the drive will detect mechanical weakening.

■ L6-11: Mech Fatigue Hold Off Time

No.

(Hex.)

Name Description

Default

(Range)

L6-11

(046B)

Mech Fatigue Hold Off Time

Sets the time that the drive will start mechanical deterioration detection triggered by the cumulative

operation time of the drive.

0 h

(0 - 65535 h)

When the total operation time of the drive is more than the value set in L6-11, the drive will detect mechanical

weakening. Use U4-01 [Cumulative Ope Time] to monitor the drive total operation time.

◆ L7: Torque Limit

The torque limit function limits the internal torque reference for the drive to and keeps the torque from the motor

constant. This function limits the torque applied to loads and regenerative torque to a value less than a set quantity.

This function also prevents damage to machinery and increases the reliability of continuous operation. You can set

torque limits individually for the four quadrants, which include torque direction (motoring/regeneration) and direction

of motor rotation (forward/reverse). When the torque reference value is at the set torque limit, the MFDO terminal set

for During Torque Limit [H2-xx = 30] activates.

Note:

• The drive output current limits maximum output torque. The drive limits torque to 150% of the rated output current for Heavy Duty Rating

(HD) and to 110% of the rated output current for Normal Duty Rating (ND). The actual output torque is not more than the limits of the

drive rated output current when you set the torque limit to a high value.

• When you use torque limits for lifting applications, do not lower the torque limit value too much. When the torque limit function is

triggered, falls and rollbacks can occur because of sudden acceleration stops and stalls of the motor.

Loading...

Loading...