n064: Frequency Reference Loss Detection Factory setting: 0 (disabled)

Range: 0 or 1

The reference loss detection function is either enabled or disabled, based on the setting

of n064. When enabled (data " 1 "), the reference loss detection compares the change in

reference with respect to time. If the reference decreases by 90% in more than 0.4

seconds, the drive will decelerate to the set reference; if the reference decreases by 90%

in less than 0.4 seconds, the drive will continue to operate at 80% of the output

frequency. To regain control of output frequency, either exceed the set reference (80% of

reference) or initiate a STOP command. If Auto Reference is less than Fmax (n011) x .05,

this function is not performed.

5-57

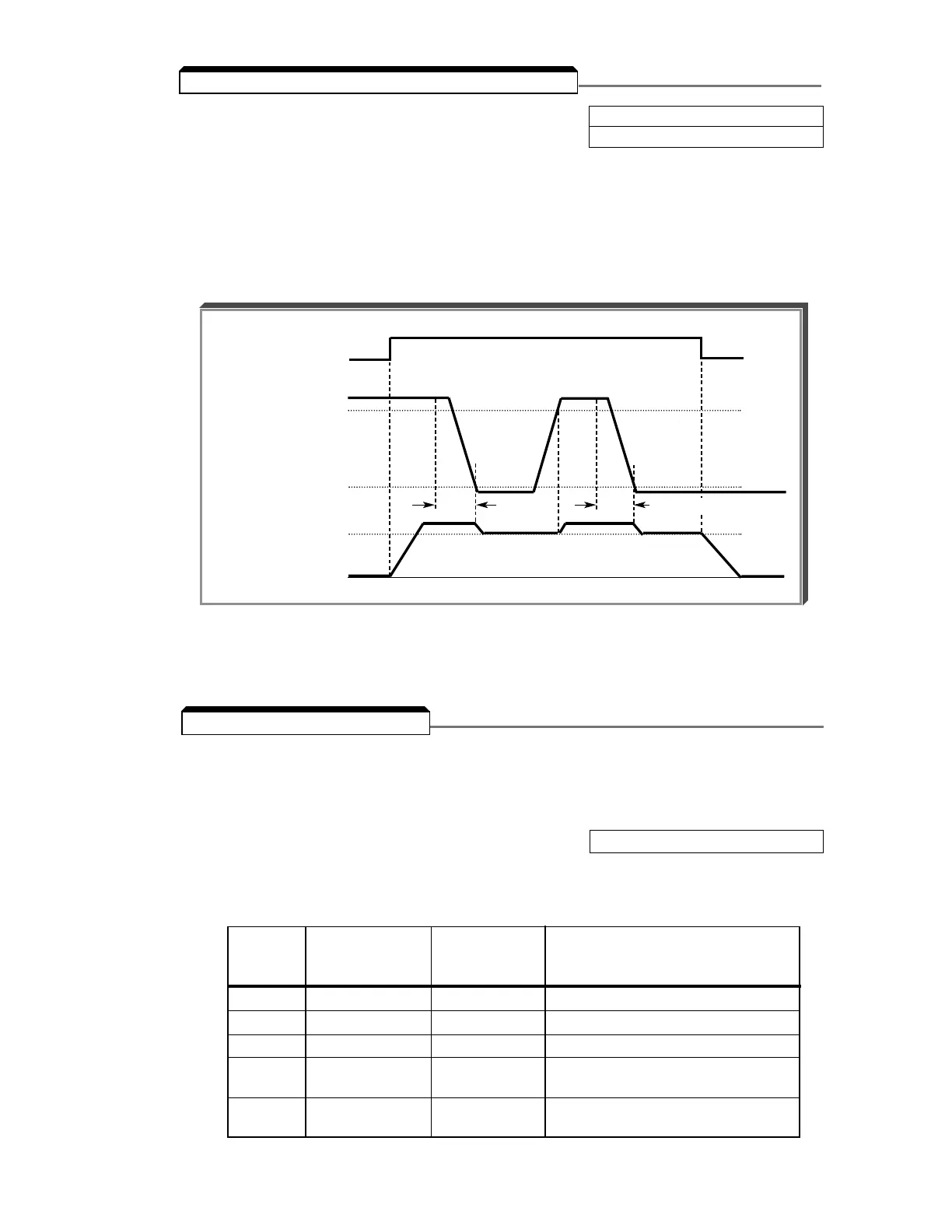

FWD RUN

COMMAND

AUTO

REFERENCE

GPD 515

OUTPUT

FREQUENCY

80%

REF

10%

80%

FREQ.

0.4 SEC 0.4 SEC

Timing Chart

5.33 FREQUENCY REFERENCE LOSS DETECTION

Note: This function applies to frequency references at terminal FR, RP or 2CN (Multi-Function

Analog Input).

Undertorque detection is used to compare Drive output current/torque with the undertorque

detection level. When the output current is equal to or less than the defined level, an undertorque

condition exists. This will be indicated as a UL3 fault on the Digital Operator. This feature can be

selected to operate over a wide range of conditions.

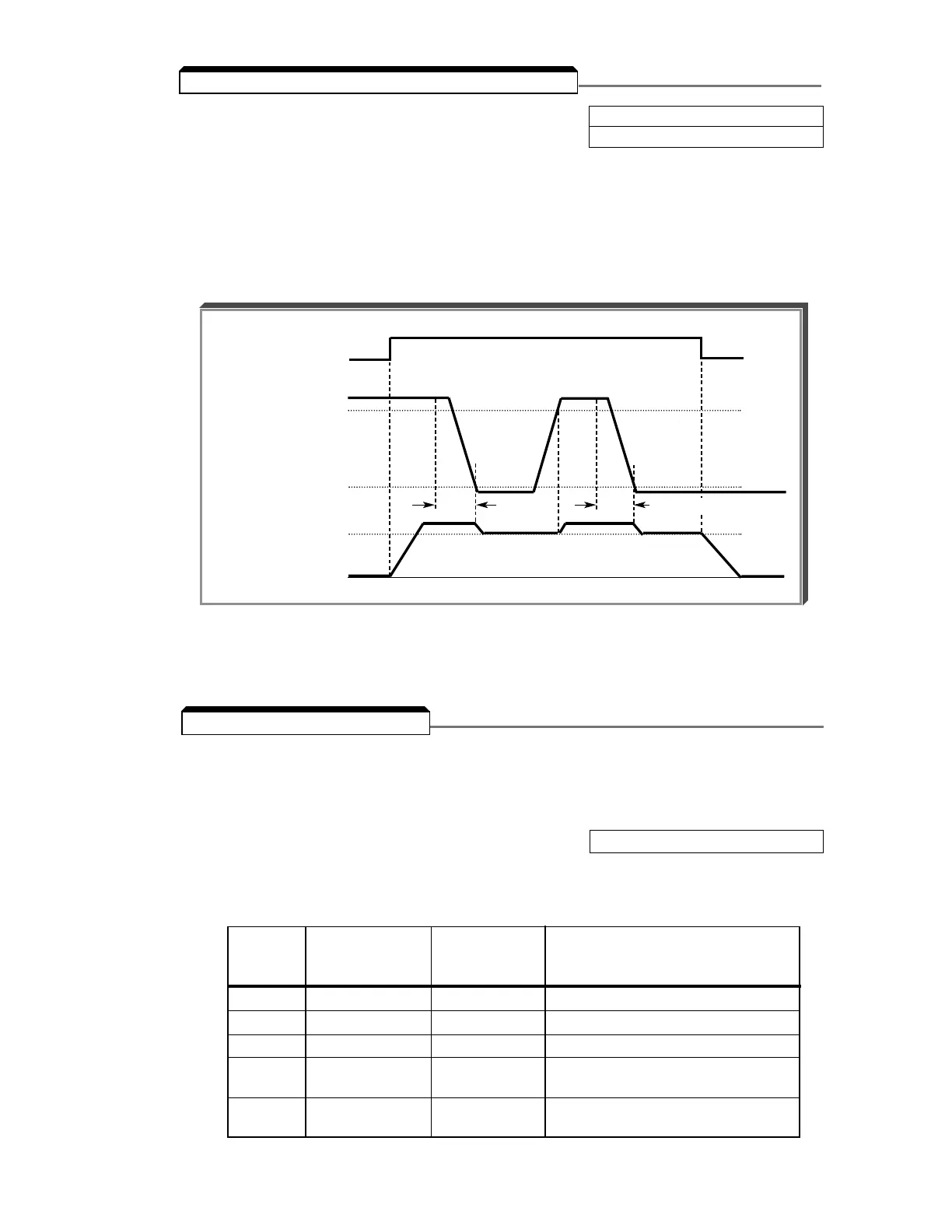

A. n117 : Undertorque Detection Factory setting: 0

This constant determines whether the undertorque detection function of the Drive is enabled, under

what conditions it will detect for undertorque, and what operation it will perform after detecting an

undertorque.

Operation

Undertorque After Detection

Setting Disabled Detection Condition

0 Disabled —— ——

1 Undertorque Continues Only at set frequency

2 Undertorque Coast to stop Only at set frequency

3 Undertorque Continues At all times except during

stopping or DC injection braking

4 Undertorque Coast to stop At all times except during

stopping or DC injection braking

5.34 UNDERTORQUE DETECTION

Loading...

Loading...