Information

•

Pay attention to a sufficient screw-in length in the motor flange.

•

An excess screw length of max. 3 mm is permissible.

•

Every screwing case is different. The tightening torque adapted to it must be determined by the

appropriate screw tests.

•

In the case of a vertical motor axis, the respective lower drain hole must be open.

•

Secure fan connection cable with cable fasteners or cable clips.

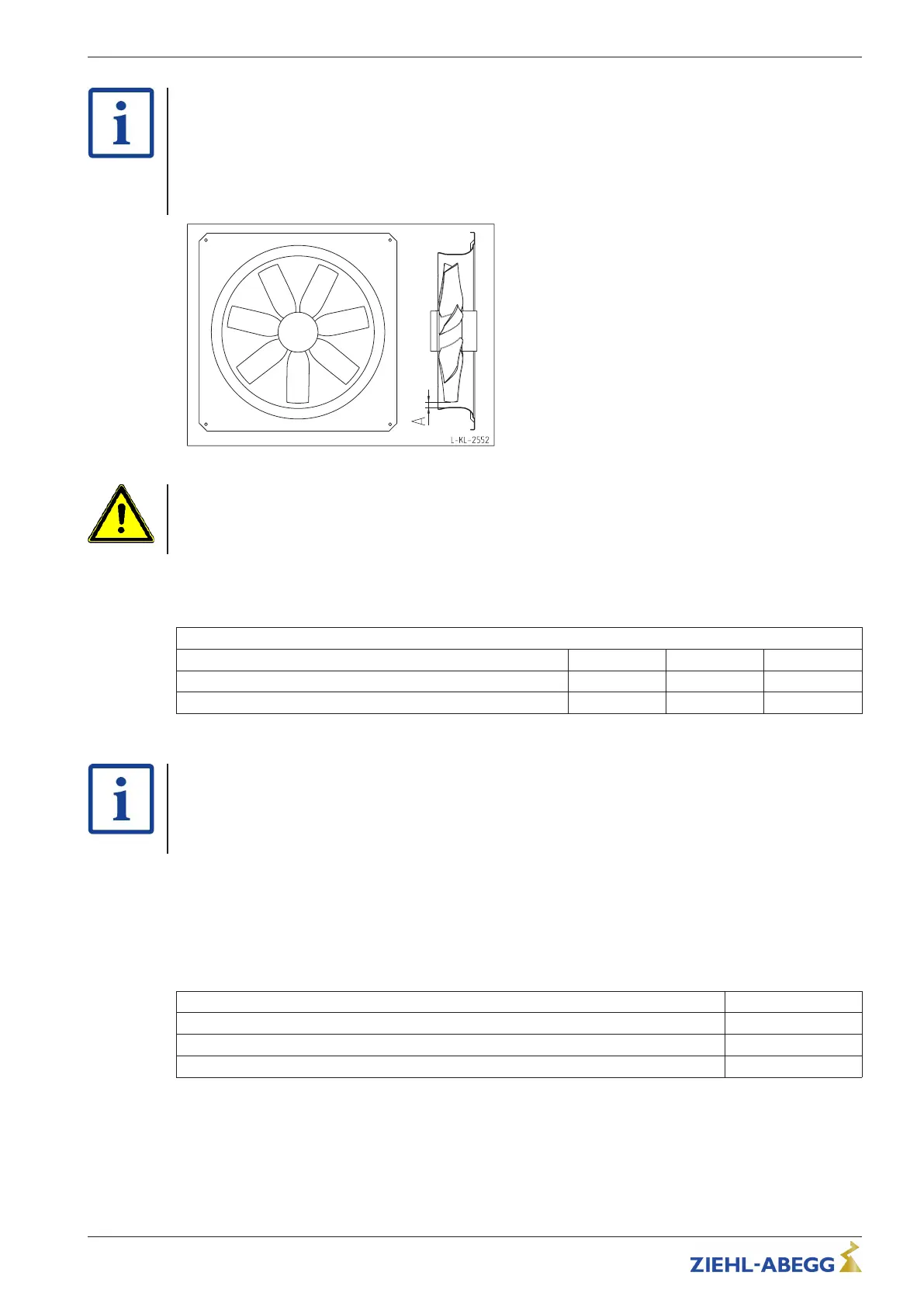

A minimum head gap “A” of 2.5 mm in all installation

positions but especially in installation position “H” (horizon-

tal motor shaft) is necessary. Distortion due to uneven sur-

face may lead to fan failure due to brushing against the fan

wheel.

Attention!

Avoid structural damage or stress with installation. Make sure the surface is flat and even.

4.6.2 ZAplus fans

When mounting ZAplus fans, ensure plastic-compliant connectors.

Recommended tightening torques M

A

when using flat fastening discs according to EN ISO 7089 or DIN125

ZAplus size (type: ZC.., ZG.., ZN.., ZF..) 040 045 - 063 > 071

Thread size

M8 M10 M12

Property class 8.8, friction coefcient µges = 0.12 12 Nm 24 Nm 40 Nm

Tightening torque guard grille fitting: 6 Nm

Information

•

Since the concrete bolt or screw varies by customer unit, these recommendations must be checked

for each respective situation.

•

Secure the cable covering against loss after connecting the motor by securing with 2 cable ties.

•

For a version with a square rear wall (design Q), removal of this square plastic plate is prohibited.

4.7 Mounting of centrifugal fans

4.7.1 Mounting of centrifugal fans design RE, RH, RZ

For attachment to fixed motor flange use screws with property class 8.8 to EN ISO 4014 and provide

with suitable screw locking.

Permissible tightening torques M

A

Thread size M6

Property class 8.8, friction coefcient µges = 0.12 9.5 Nm

Screw penetration ≥ 1.5 x d

When using screws with different friction values or strength classes, different tightening torques may

be necessary.

Mounting of centrifugal fans, RZ design

Attachment to motor fan wheel mounting according to device manufacturer's specifications.

Assembly instructions ECblue Mounting

L-BAL-F055D-GB 2021/51 Index 006 Part.-No.

13/56

Loading...

Loading...