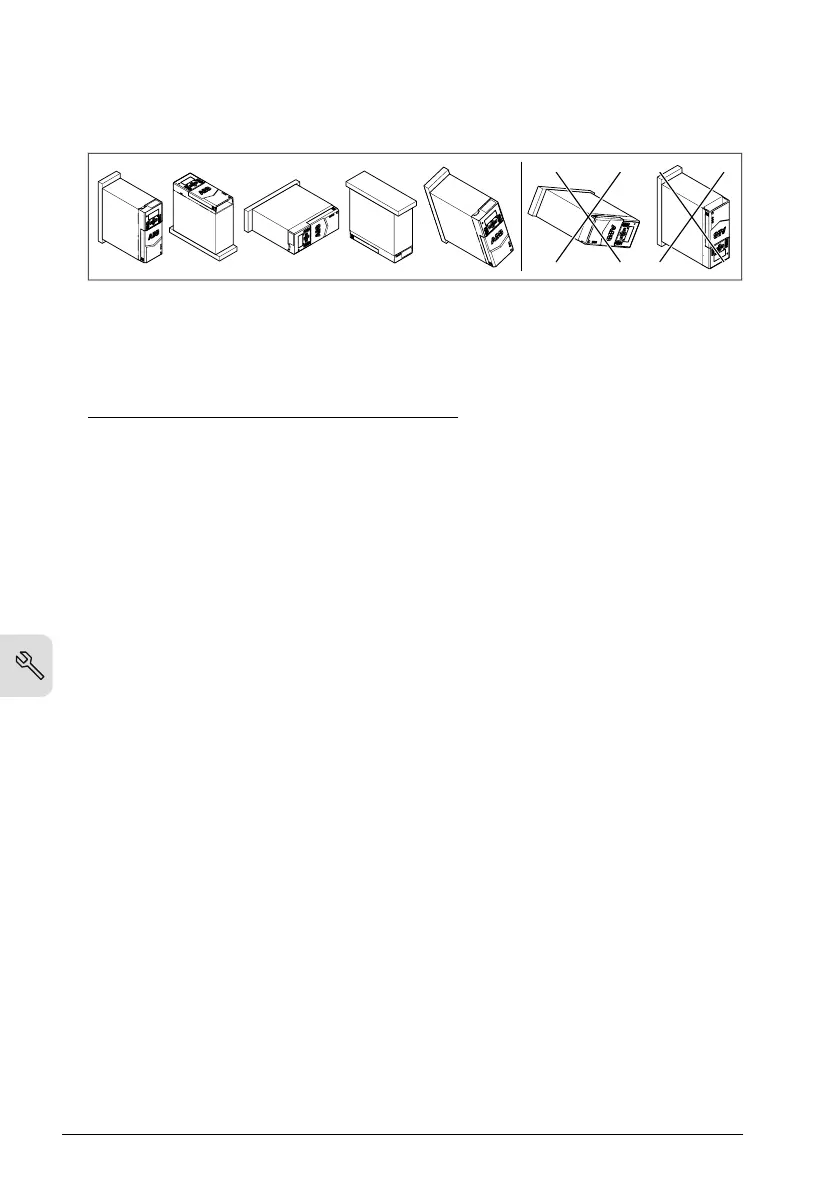

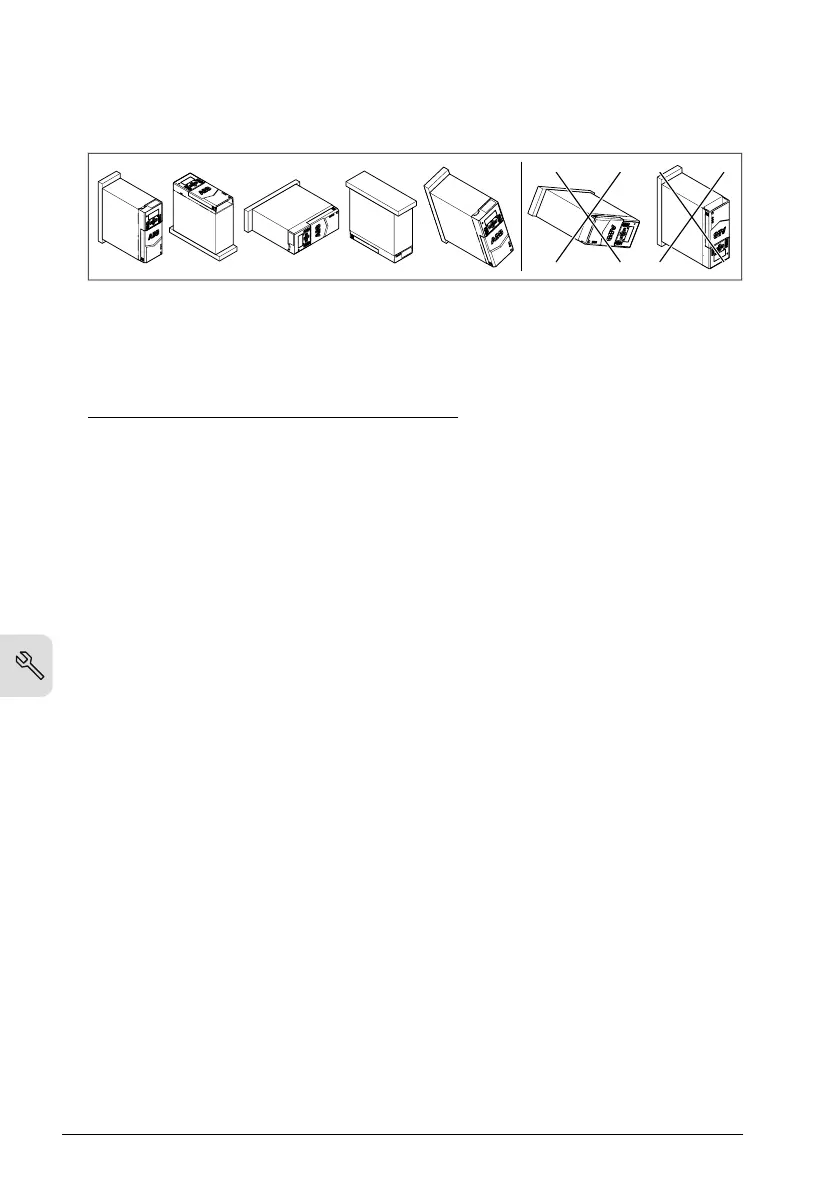

• You can install frames R1, R2, R3 and R4 tilted to a maximum of 90 degrees, from

vertical to fully horizontal orientation.

• Do not install the drive upside down.

• Make sure that the hot exhaust air from a drive does not flow into the cooling inlet

of other drives or equipment.

• Drives equipped with the optional UL Type 1 kits: If you install the drives side-by-side,

make sure that their air outlets do not face each other.

Examining the installation site

Examine the installation site. Make sure that:

• The installation site is sufficiently ventilated or cooled to remove heat from the drive.

See the technical data.

• The ambient conditions of the drive meet the specifications. See the technical data.

• The wall behind the drive and the material above and below the unit is of

non-flammable material.

• The installation surface is as close to vertical as possible and strong enough to

support the drive.

• There is sufficient free space around the drive for cooling, maintenance, and

operation. See the free space specifications for the drive.

• Make sure that there are no sources of strong magnetic fields such as high-current

single-core conductors or contactor coils near the drive. A strong magnetic field can

cause interference or inaccuracy in the operation of the drive.

Required tools

To install the drive mechanically, you need these tools:

• a drill and suitable drill bits

• a screwdriver or wrench with a set of suitable bits

• a tape measure and spirit level

• personal protective equipment.

44 Mechanical installation

Loading...

Loading...