30 AO2000 CONTINUOUS GAS ANALYZERS | OI/AO2000-EN REV. B

Caldos25, Caldos27, Magnos206: Version for the 'Safety Concept'

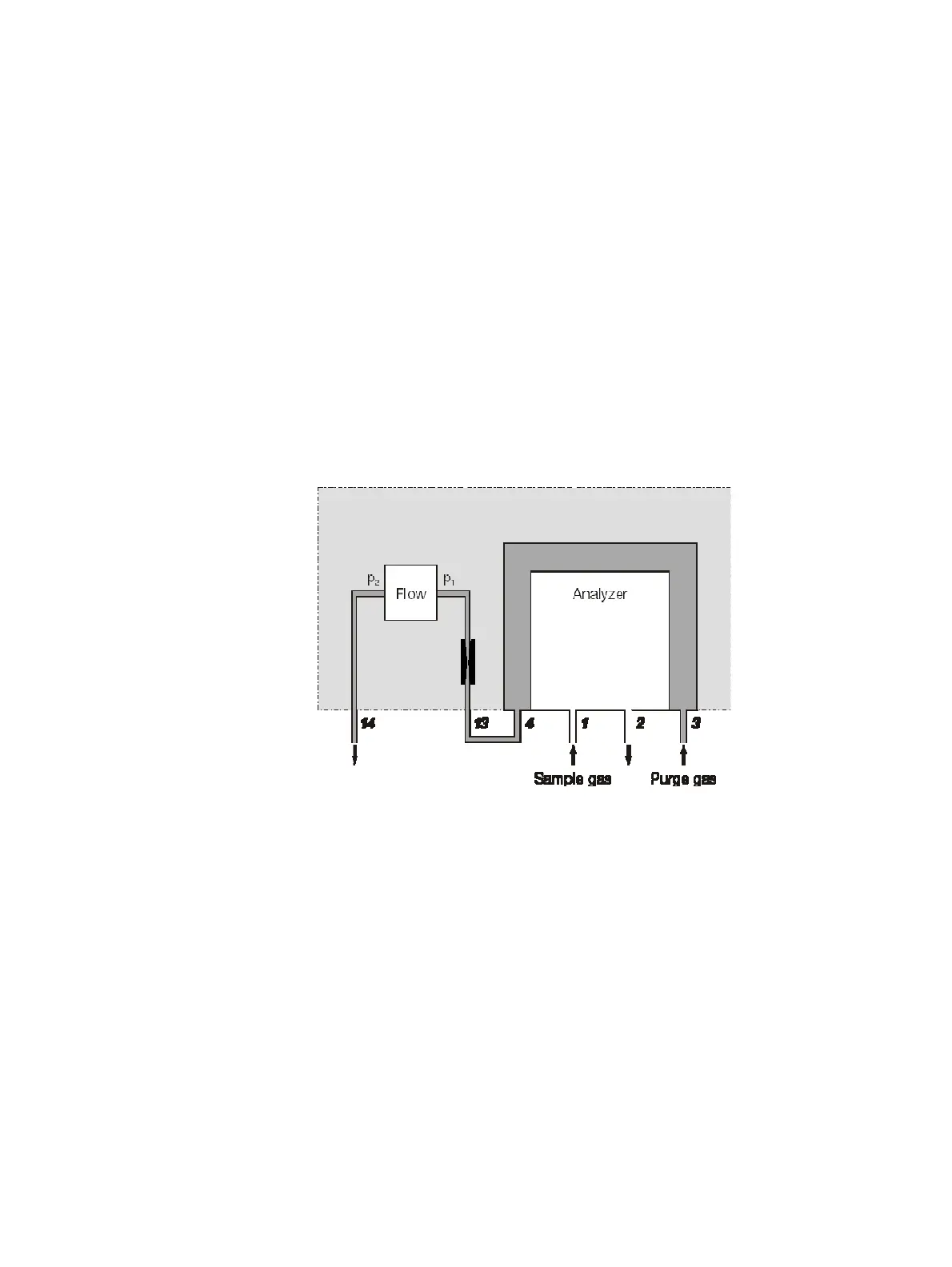

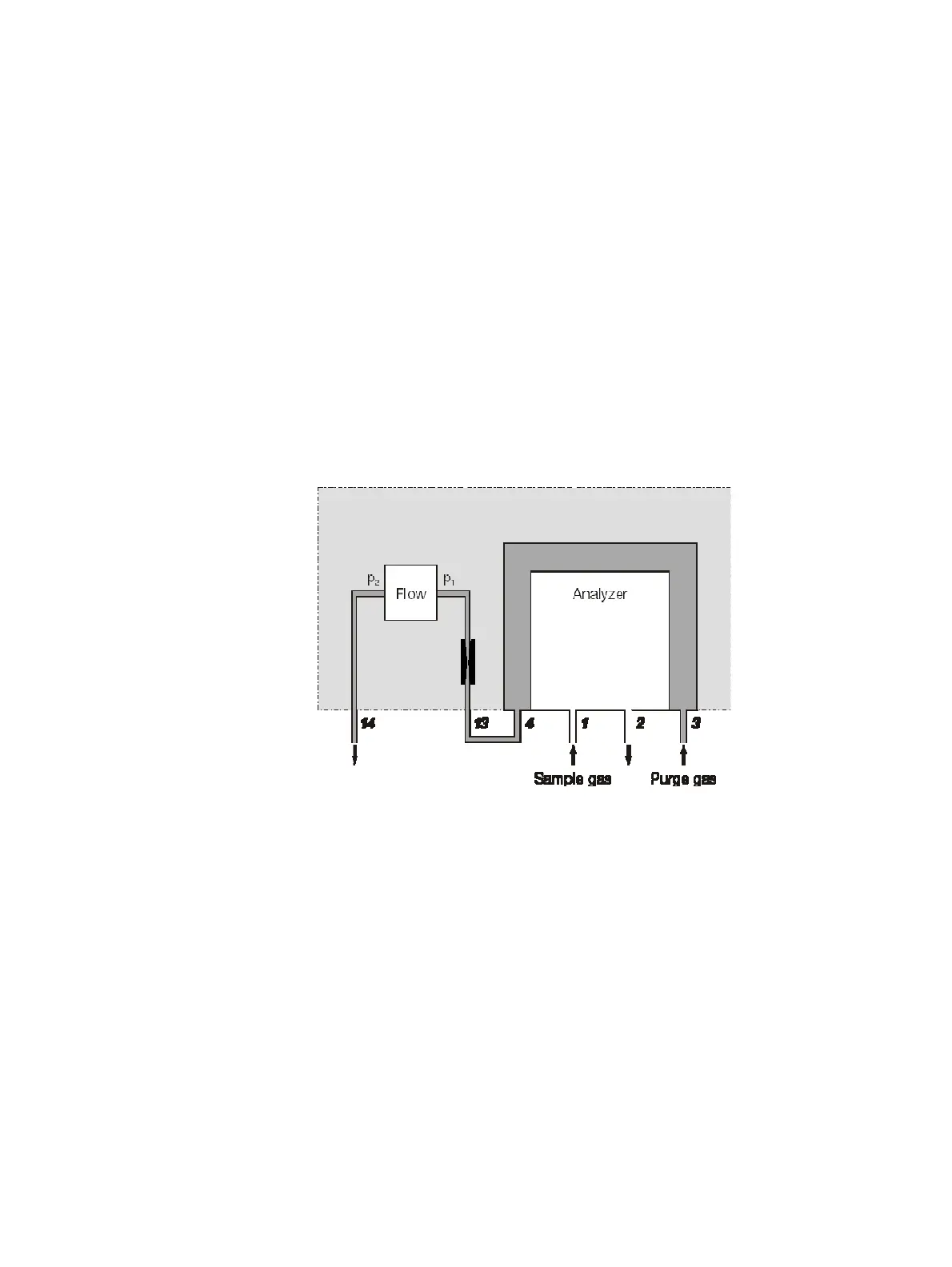

Purging of the thermostat chamber

The thermostat chamber that encloses the analyzer is flushed with purge

gas at a slight positive pressure. The purge curtain formed in this manner

comprises all of the parts of the sample gas path. In the event of a leak in the

sample gas path, the purge gas flows into the analyzer and, in this way, pre-

vents flammable gases from emerging from the analyzer module.

The purge gas is introduced at a flow rate of 15 to 20 l/h and a positive

pressure of p

e

≤ 50 hPa to the thermostat chamber. As a result of the capil-

lary, a positive pressure of p

e

= 7 to 20 hPa is established. The purge gas flow

is measured by a flow meter located downstream from a capillary in the

sample gas path. The outlet pressure should be open to atmospheric pres-

sure.

The signal from the flow sensor is monitored and evaluated by a function

block application (see section "Monitoring of purge gas flow" (see page 32)).

Purge curtain

1

Sample gas inlet

2

Sample gas outlet

3

Purge gas inlet thermostat chamber "Analyzer Purge In"

4

Purge gas outlet thermostat chamber, ex works tubed with 13

13

Purge gas inlet flow monitoring

14

Purge gas outlet flow monitoring "Analyzer Purge Out"

Loading...

Loading...