3 System Description

3.2 Basic Design

22 3HNA009834-001 en Rev.06 Product Manual, Control Cabinet IRC5P

3.2.4 Purge System

General When the robot is installed in an area where explosion hazard is present, it is

equipped with a purge system. The purpose of this system is to apply compressed

air in the manipulator. The compressed air is kept at a higher pressure than the

atmospheric pressure and so preventing hazardous gases from entering the

manipulator interior.

For more details on the purge unit, see ‘Unit Description, IRC5P’, Purge System.

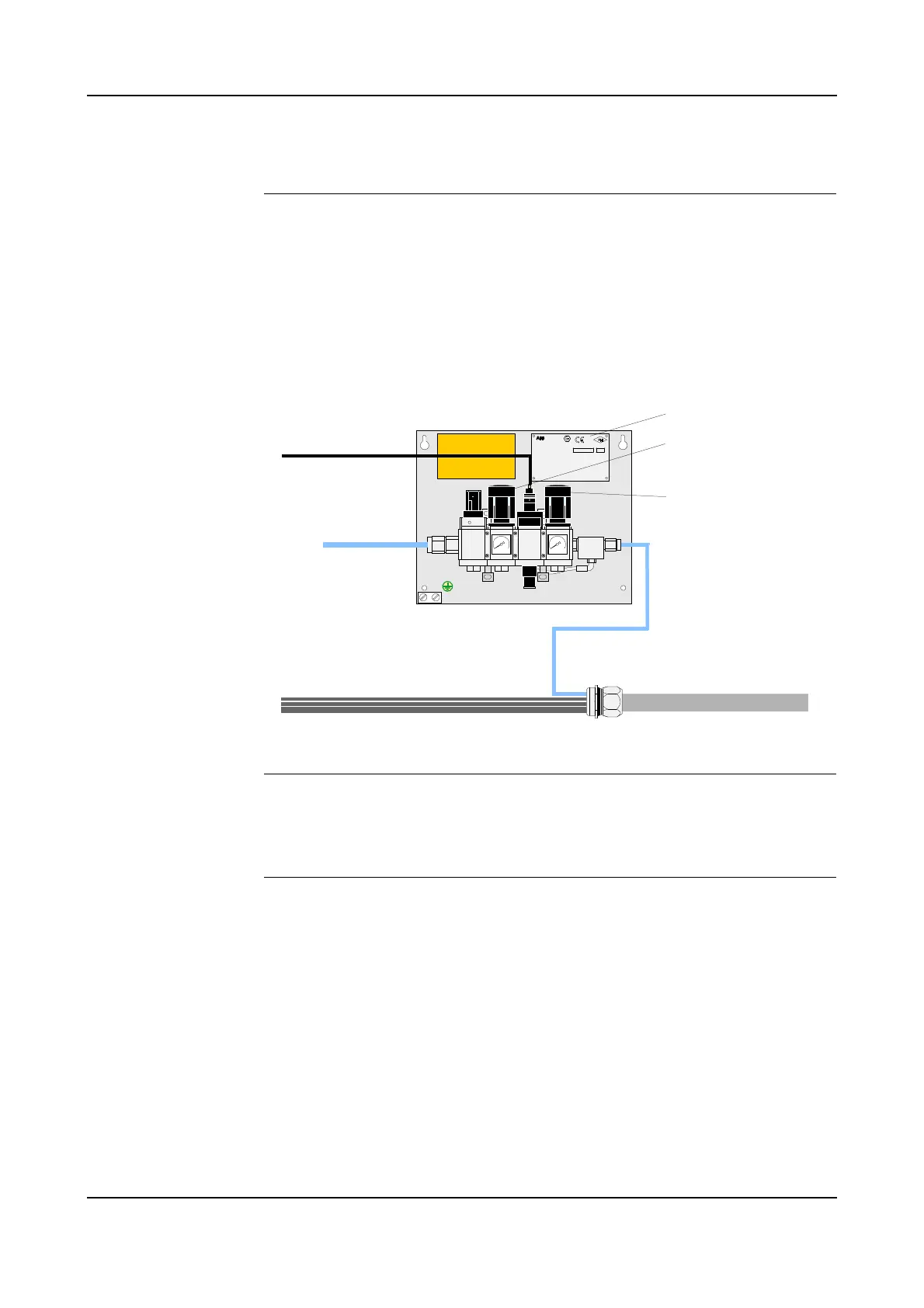

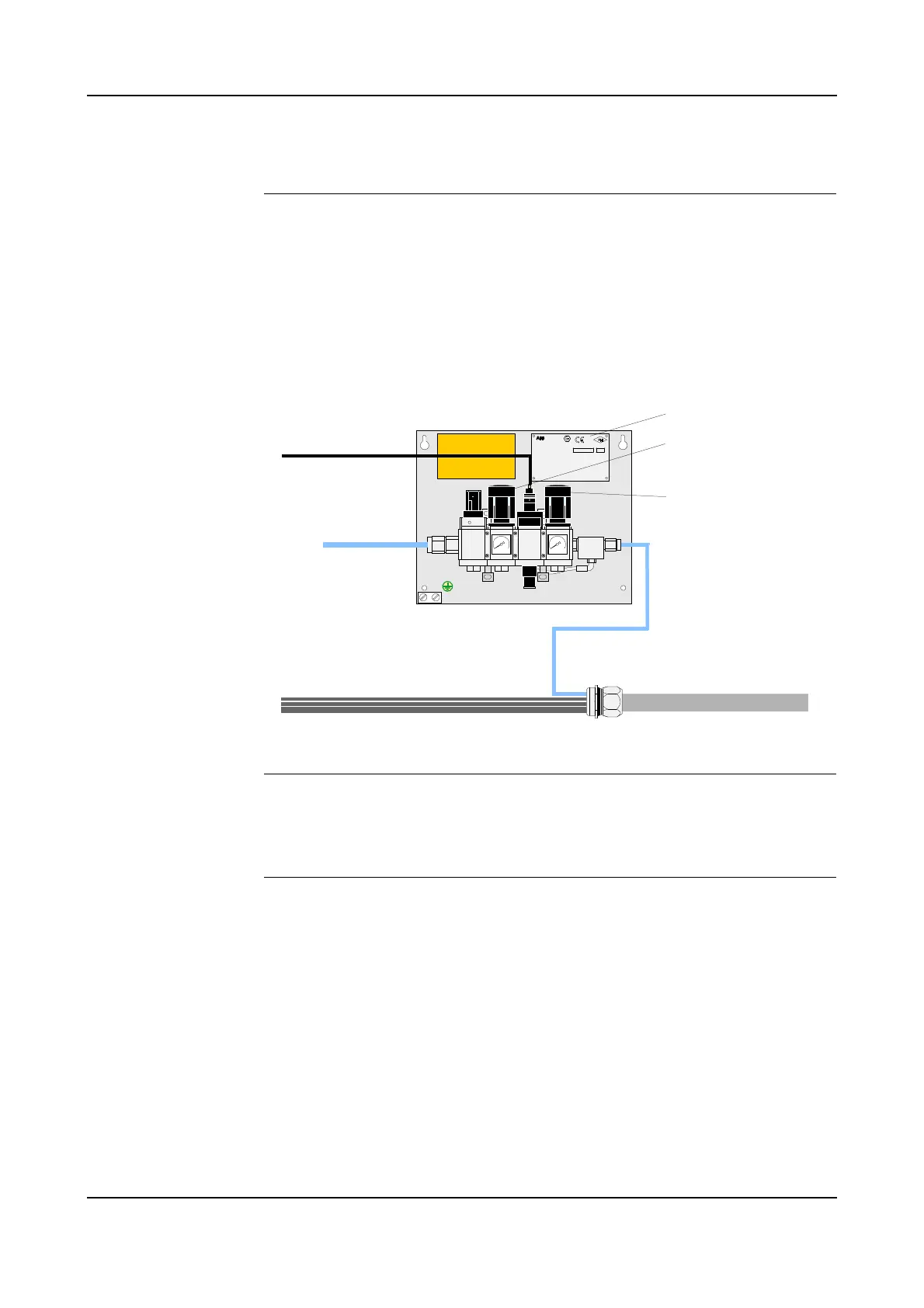

Figure 5 Purge unit design

Description The purge valve assembly includes various valves for controlling and regulating the

purge air supply to the robot. Supply air is connected to the purge unit and, via the

control valves, routed to the manipulator via the purge connector and flexible hose.

Versions Different versions of the purge unit are available:

The purge unit shown in the above illustration is used for all stand-alone robots.

For robots operating on a trolley, a different type of purge unit, called ‘Purge Unit

with Connector Box’, is used. This purge unit includes a purged chamber with cable

connections. The main reason for using this type is to provide flexible cables via the

trolley cable chain. For information on this purge unit type, see ’Purge Unit

w/Connector Box’ on page 111.

Purge supply to dry filtered

air only (instrumental air)

Purge pressure:

WARNING! PRESSURIZED AIR

Not e:

3 bar (45 psi)

Mainte nance p ressure: 0,5-1 bar

TURN OFF MAIN AIR-TAB BEFO RE

WORKING ON EQUIPMENT

Purge time: See machine specification

PO Box 265, N-4349 B ryne

ABB AS, Robotics

0470

APPROVED

Type:PURGE CONNECTOR BOX

Dwg.No.: 3HNM 01201-1

Part of :PU RGE SYSTEM Dwg.N o.3HNE 06486- 1

NEMKO 02AT EX189U

Protective gas :........................... Instrumental air

Purge Suppl y press ure :............ M in.3.0 max.5.0 bar

Maintenanc e Supply press ure :. M in.0. 5 max.1.0 bar

Leaquage C ompensation : ........... 5 -20 Nl/min.

Maintenanc e press ure :................. Min. 0.8 mbar

Enclosure Pressure :..................... Max. 500 mbar

BatchSerial No.

INTRINSICALLY SAFE SIGNALS Cl. I.II. Div. 1 , Gr. A - G

[EEx pib] IIB

II ( 2) G,D

Supply air

Flexible hose

to manipulator

Motor and

control signals

Purge valve

control signal

Purge connection

Purge valve assy'

Purge air

hose

Purging (Flushing)

pressure regulator

Maintenance pressure

regulator

Identification label

Loading...

Loading...