5 Installation and Commissioning

Product Manual, Control Cabinet IRC5P 3HNA009834-001 en Rev.06 47

5.2 Component Installation

5.2.2 Lifting and Transporting the Controller

General The control cabinet is shipped on a transportation pallet at an upright position.

Weight of the control cabinet is given in ’Controller Specifications’ on page 32.

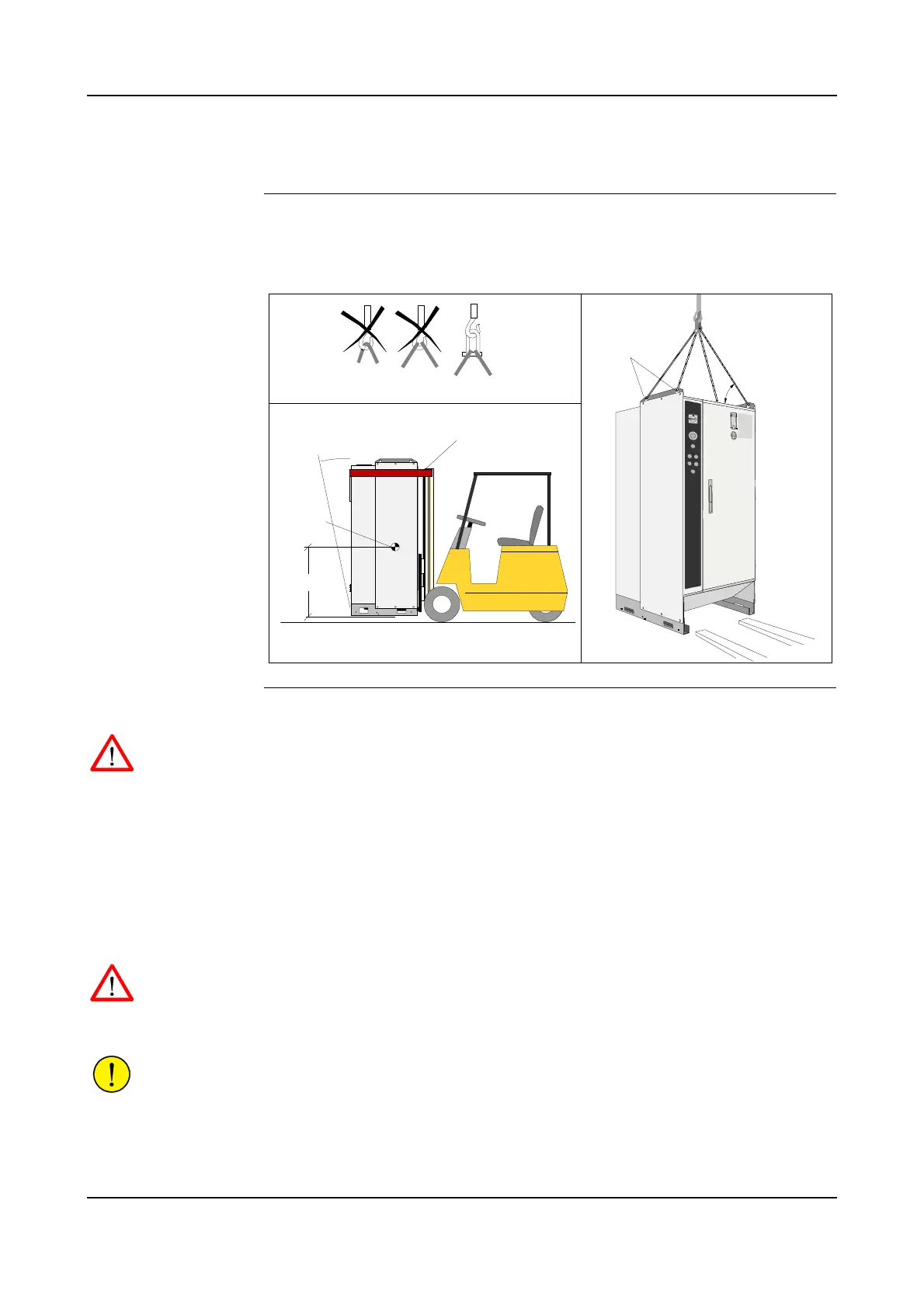

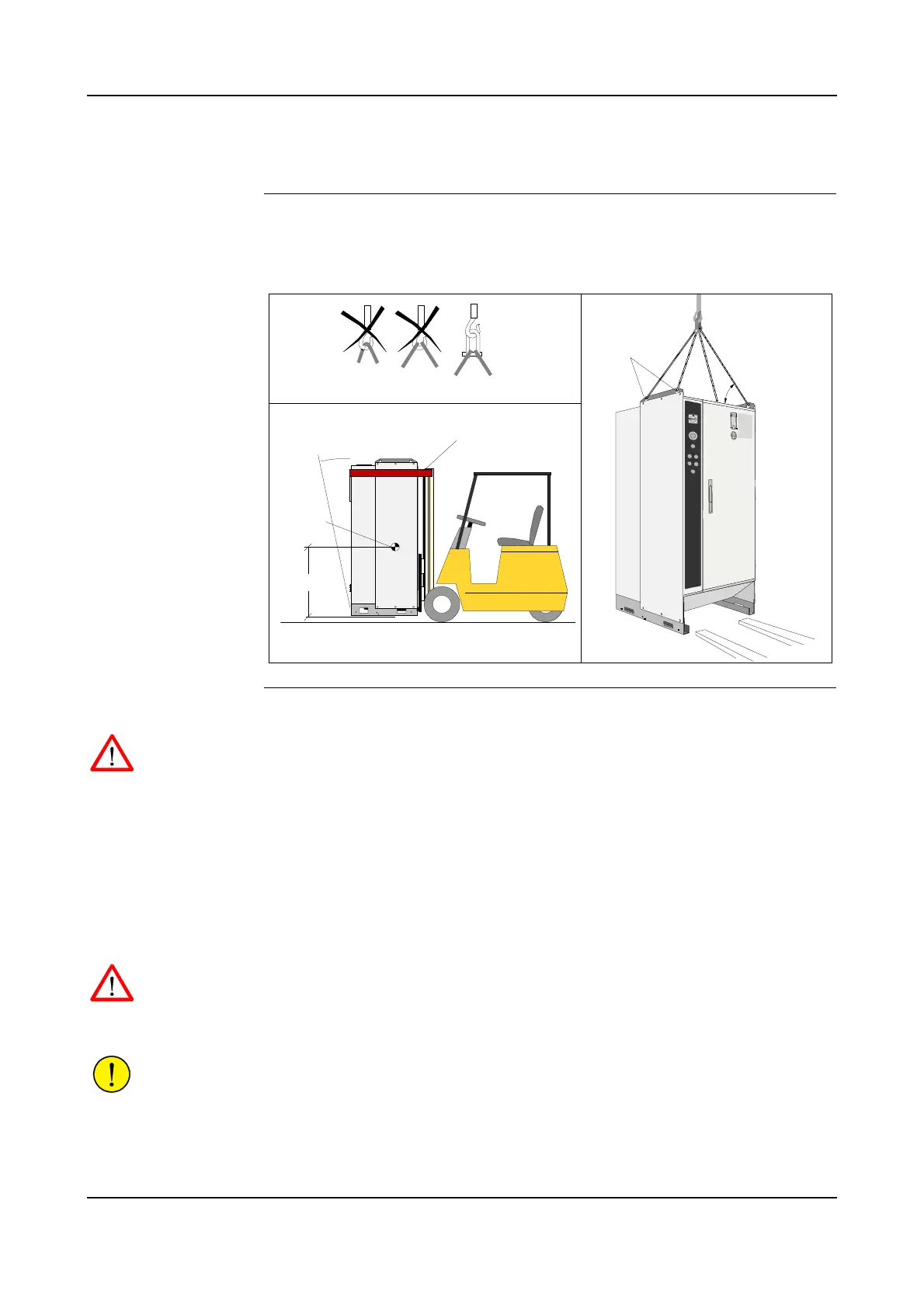

Figure 20 Control cabinet lifting

Procedure This procedure describes how to lift and transport the control cabinet.

WARNING! Attach the top of the cabinet to the fork lift using a strap or similar to

prevent it from tipping over by braking etc. See Figure 20, lower left illustration.

1. After having unloaded the control cabinet crate from the lorry, use a fork lift

and transport the cabinet to the installation site or as close to the site as possible

before removing it from the pallet.

2. Unpack the supplied packages and check that the content is correct and

undamaged.

3. Place the cabinet on the floor and remove packing material.

WARNING! Do not walk under the hanging load.

4. Transport the cabinet to its permanent location using an overhead crane or fork

lift. See Figure 20, lower left and right illustration.

CAUTION! If lifting straps are used, they must be attached to all 4 lifting eyes.

For information on location of the cabinet and information on how to secure the

cabinet to the floor, etc., see ’Cabinet Location’ on page 48.

Lifting eyes

Min. 45°

Lifting by

fork lift

Max. 17.5°

Safety strap

Transporting cabinet by fork lift

Lifting by

overhead crane

Lifting strap attachment to hook

Center

of gravity

Lifting the cabinet

1 meter

Loading...

Loading...