5 Installation and Commissioning

5.6 Encoder and Sync Switch Installation

94 3HNA009834-001 en Rev.06 Product Manual, Control Cabinet IRC5P

5.6.6 Sync. Switch Installation

General The sync switch may be positioned to detect the work object suspension or the work

object directly.

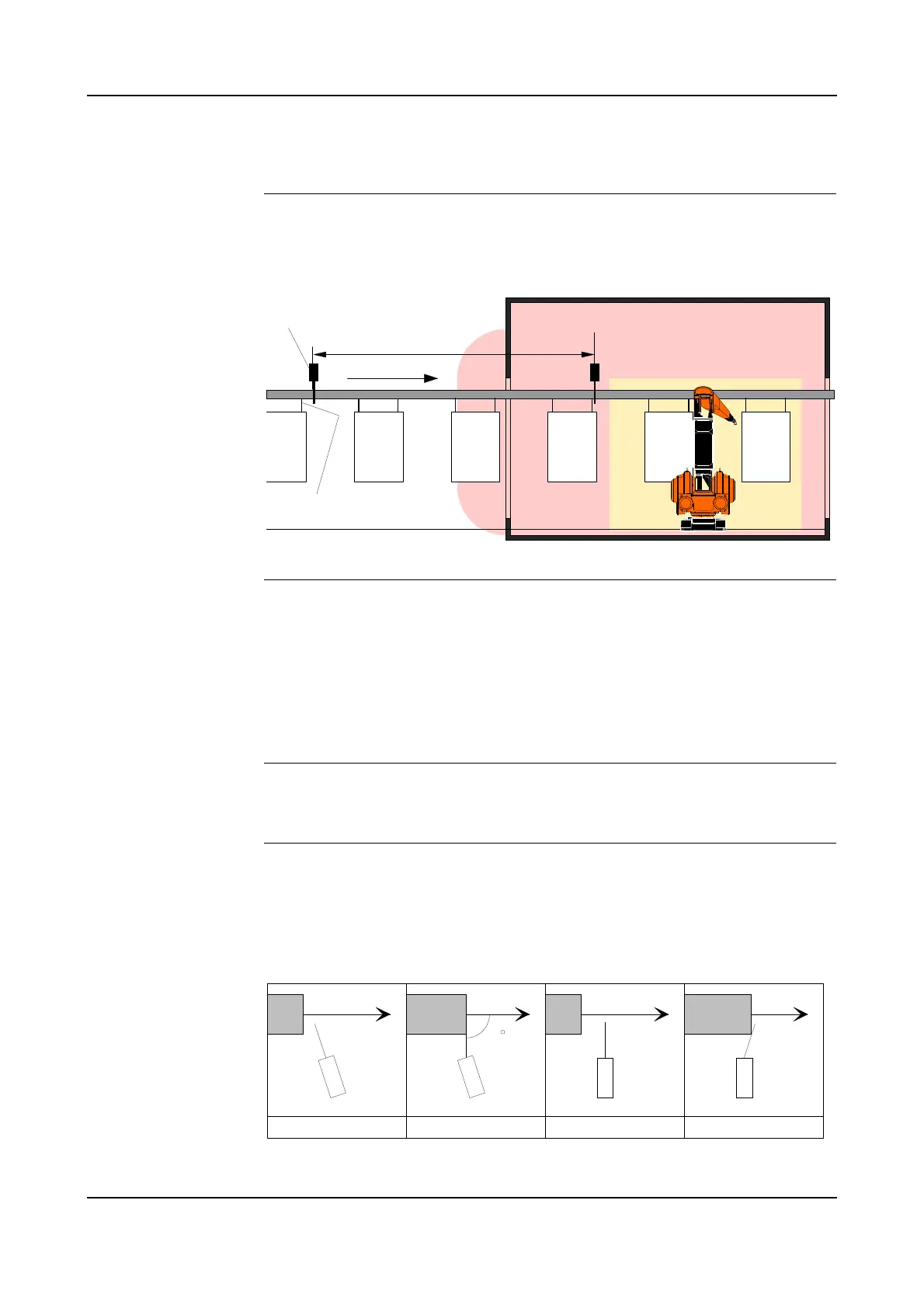

Figure 42 Location of sync switch in an installation

Location of Switch To reduce possible variation in the synchronization signal due to uneven conveyor

motion, swinging of work objects etc., the switch should be placed as close to the

robot as practically possible.

The switch may also be placed outside the hazardous area. This location must be

used if a non-ex switch and non-ex connection is used. The switch can be installed

on a bracket mounted on the conveyor.

Initiator Mounting If an initiator is used, the initiator should be installed to detect the object directly, or

detecting the object suspension (a flag on the suspension) etc.

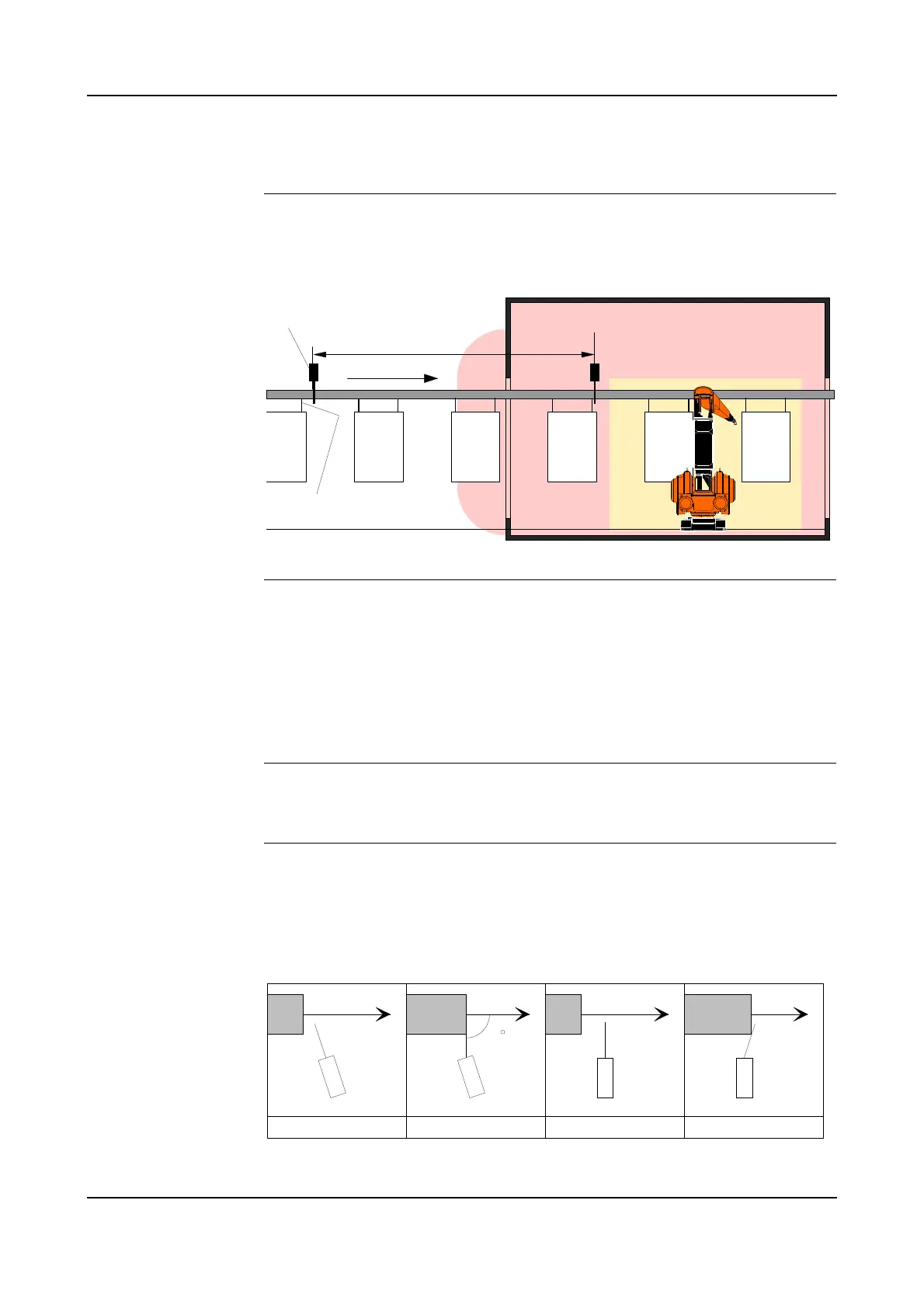

‘Normal’ Switch

Mounting

If a ‘normal’ switch is used, the switch arm must be in a perpendicular position in

relation to the work object when the switch is activated. If the switch is installed as

indicated in the two illustrations at the right, there is a risk that the work object (or

suspension) will slide on the switch arm, causing inaccurate switching.

Figure 43 Sync switch mounting

Robot

working

area

0.0 point

Non-ex

Sync switch

Sync switch

trig point

Queue tracking distance

Spray booth

Hazardous area

Hazardous area

outside entrance

Ex Sync switch

90

CorrectCorrect Not correct Not correct

Loading...

Loading...