MNALAZIN-02 25

Integration in the Servo System / Mounting

Soldering SolderinganAZboarddirectlytoaPCBprovidesaddedsupportagainstmechanical

shocksandvibration.ItisrecommendedtosolderAZdrivestoaPCBfollowingtheindustry

standardforAcceptabilityofElectronicAssembliesIPC‐A‐610D.Usesolderwithno‐cleanflux.

AZdrivescanbesolderedbyanyofthefollowingmethods:

• wavesoldering

• handsoldering

• selectivewavesoldering

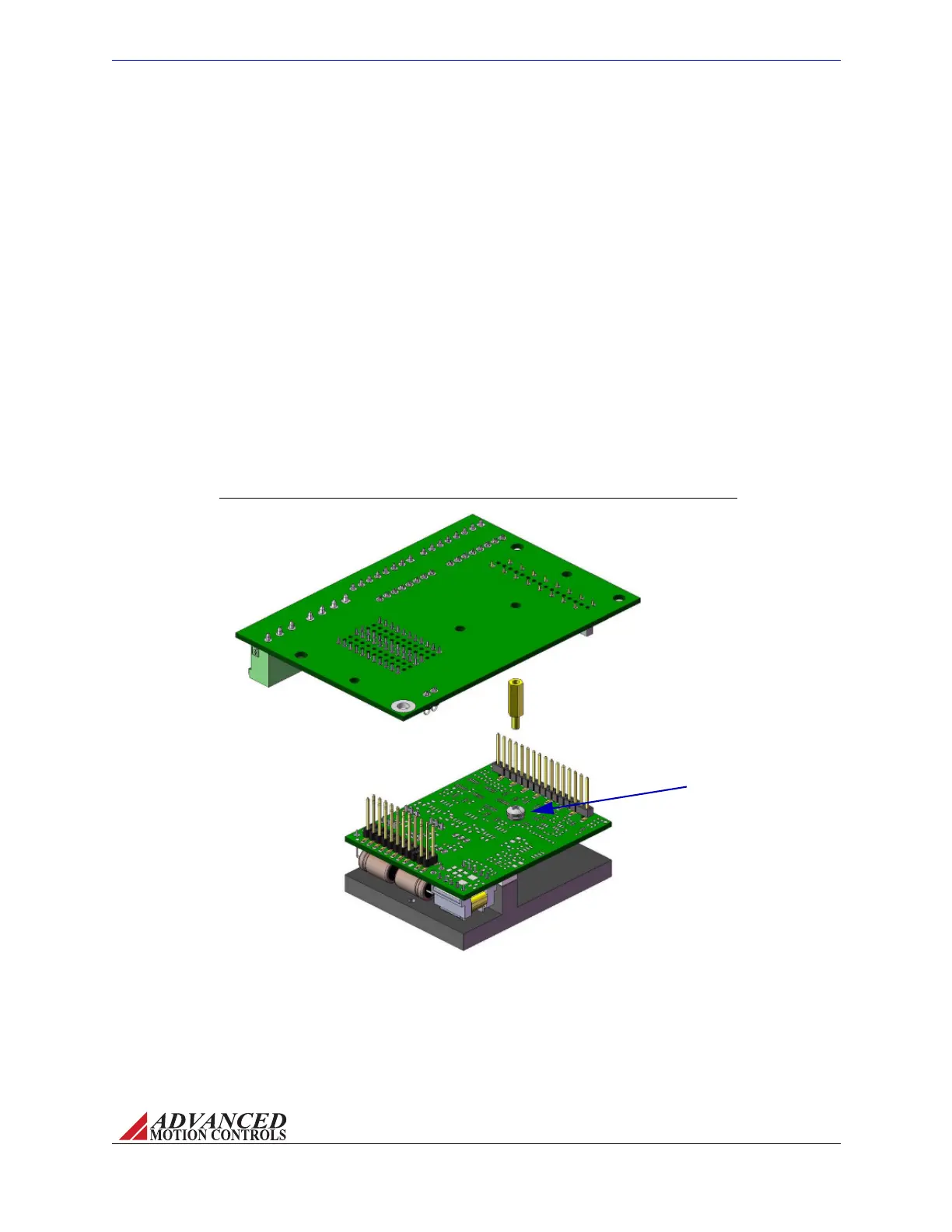

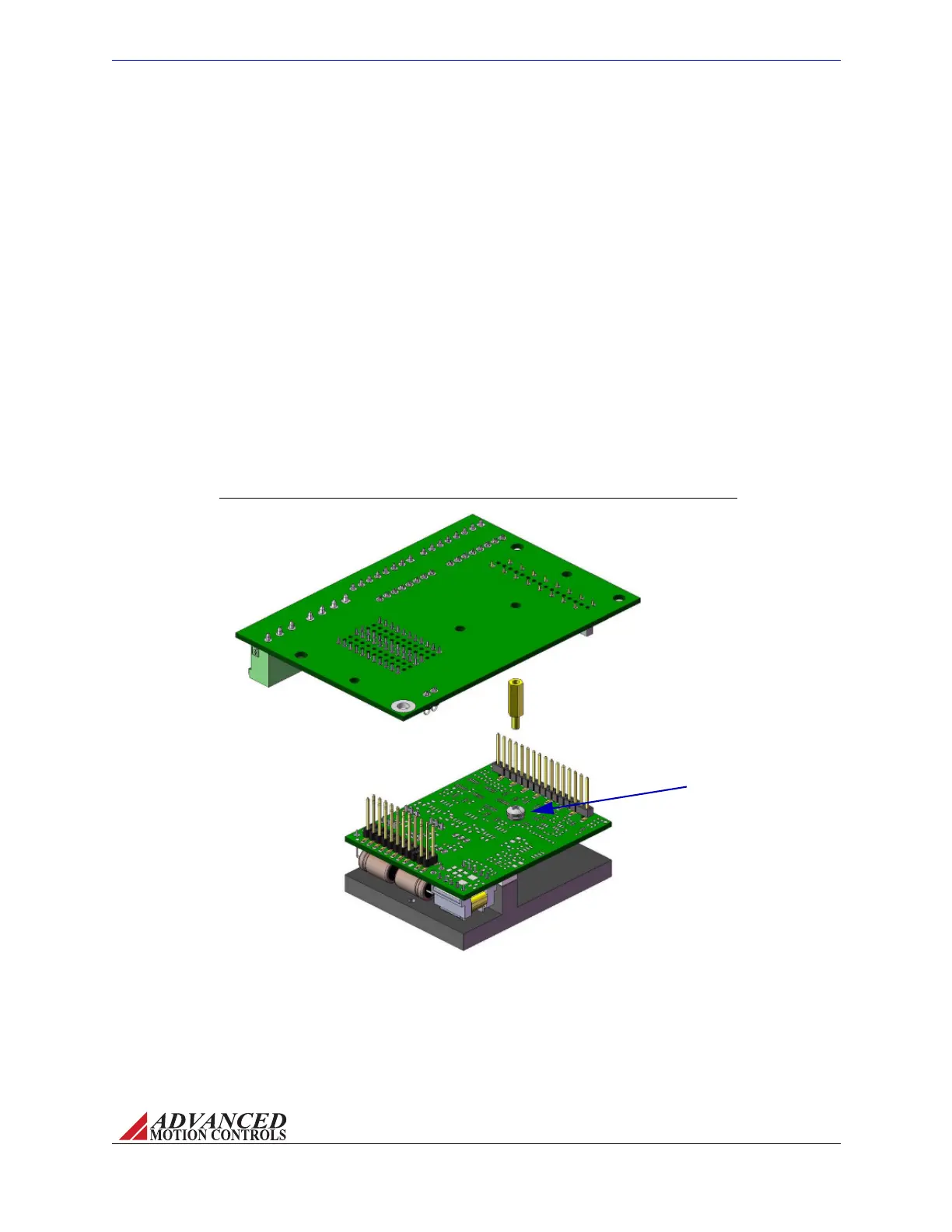

FIGURE 3.5

Remove drive mounting screw,

and replace with spacer*. Use

the removed drive mounting

screw to secure mounting card

to drive from the bottom of the

mounting card through the

spacer after drive has been

inserted in mounting card

socket connectors.

*Spacer not included with AZ drive or

mounting card. Spacer shown is

standard 3/16" hex 4/40 thread,

male/female, 7/16" length.

Drive Mounting Screw

AZ20 Screw Mount Diagram

TocleanthePCBanddriveaftersoldering,itisrecommendedtogentlyapplyisopropylalcohol

oracleaningagentwithasoft‐bristledbrush.Usecarenottoapplydownwardpressure,but

ratherlightlybrushthePCBanddrive.Donotimmersethedriveinacleaningagent.

Screw Mounting Foraddedstabilityandsupport,AZdrivescanbemountedwithscrewsin

tandemwithoneoftheoptionsabove.Figure3.5showshowanAZ20drivecanbemountedto

theMC1XAZ01mountingcardusingaspacer.See“PhysicalDimensions”onpage39and/or

thespecificdrive’sdatasheetforexactscrewlocationsanddimensions.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...